Stainless Steel 316/ 316L/ 316Ti Buttweld Fittings

Stainless Steel 316L 1.5D Elbow, SS 316 Long Stud End, SS 316Ti 180 Degree Elbow, UNS S31603 Pipe End Cap, DIN 1.4571 SR Return Bend, UNS S31600 Lateral Tee, ASTM A403 SS 316 1D Elbow, DIN 1.4301 Exhaust Pipe Reducer, 316L SS Long Radius, SS 316 Contcentric Reducer.

About Stainless Steel 316/ 316L/ 316Ti Buttweld Fittings

Stainless steel is widely used in various industrial applications due to its corrosion resistance, strength, and durability. The 316, 316L, and 316Ti stainless steel grades are popular for various applications. 316 stainless steel is an alloy that contains molybdenum, which provides additional corrosion resistance and improved high-temperature strength. It is also known for its ability to withstand harsh environments and resist pitting and crevice corrosion.

316L stainless steel is a low-carbon version of 316 stainless steel, which makes it easier to weld and reduces the risk of intergranular corrosion. This grade of stainless steel is ideal for strength and corrosion resistance applications. 316Ti is a titanium-stabilized version of 316 stainless steel. The addition of titanium provides improved resistance to intergranular corrosion and reduces the risk of sensitization, which can occur in high-temperature applications. All three grades of stainless steel are widely used in the production of buttweld fittings. Buttweld fittings connect pipes, valves, and other components in a piping system. The use of stainless steel provides long-term durability, as it resists corrosion and is easy to maintain.

In terms of mechanical properties, 316, 316L, and 316Ti stainless steel buttweld fittings have high strength and toughness, which makes them ideal for high-pressure applications. They also have good resistance to high-temperature corrosion, which is important in applications with high temperatures. In terms of welding, all three grades of stainless steel are easy to weld and fabricate, making them a popular choice for various applications. The low-carbon content of 316L and the addition of titanium in 316Ti make them particularly well-suited for welding. Stainless steel 316, 316L, and 316Ti are popular choices for buttweld fittings due to their excellent combination of strength, corrosion resistance, and durability. All three grades are easy to weld and fabricate, making them suitable for various applications.

Our company packs stainless steel 316, 316L, and 316Ti buttweld fittings in wooden crates or pallets to ensure safe and secure transportation. The fittings are covered with rust-proof material and securely wrapped to prevent any damage during transit. Our packaging ensures that the fittings reach their destination in the same condition as when they were dispatched from our facility.

SS 316Ti 3D Elbow Manufacturer, ASME SA403 SS 316Ti Equal Cross Stockist, UNS S31600 Equal Tee Manufacturer, 316Ti SS Barrel Nipple Stockist, DIN 1.4301 Reducing Tee Stockist, UNS S31603 Pipe End Cap Exporter.

Specification of Stainless Steel 316/ 316L/ 316Ti Buttweld Fittings

| Specification | ASTM A403 / ASME SA403 |

| Standard | EN, ISO, DIN, JIS, NPT |

| Dimension Standard | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Size | 1/8” NB TO 48” NB. (Seamless & 100% X-Ray Welded, Fabricated) |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Type | Seamless / Welded / Fabricated |

| Pressure-Temperature Class | 150LB, 300LB, 600LB, 1500LB, 2500LB. |

| Schedule | Schedule 5 TO Schedule XXS. |

| Type Of Dimension | BS1640, EN 10253 - 4, DIN 2605, JIS B2312, ANSI B16.9, MSS SP-75, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2313 |

Ready stock of available for Stainless Steel 316/ 316L/ 316Ti Buttweld Fittings

Equivalent Grades of Stainless Steel 316/ 316L/ 316Ti Buttweld Fittings

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST |

| SS 316 | S31600 | 1.4401 / 1.4436 | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 | SUS 316 | 316S31 / 316S33 | - |

| SS 316L | S31603 | 1.4404 / 1.4435 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 |

| SS 316Ti | S31635 | 1.4571 | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 | SUS 316Ti | 904S13 | - |

Chemical Composition of Stainless Steel 316/ 316L/ 316Ti Buttweld Fittings

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.0 - 18.0 | 2.0 - 3.0 | 11.00 - 14.00 | 67.845 min |

| 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.0 - 18.0 | 2.0 - 3.0 | 11.00 - 14.00 | 68.89 min |

| 316TI | 0.08 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 16.0 - 18.0 | 2.0 - 3.0 | 10.00 - 14.00 | 68.395 min |

Mechanical Properties of Stainless Steel 316/ 316L/ 316Ti Buttweld Fittings

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 316 | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| 316L/ 316TI | 8.0 g/cm3 | 1399 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Other Types of Stainless Steel 316/ 316L/ 316Ti Buttweld Fittings

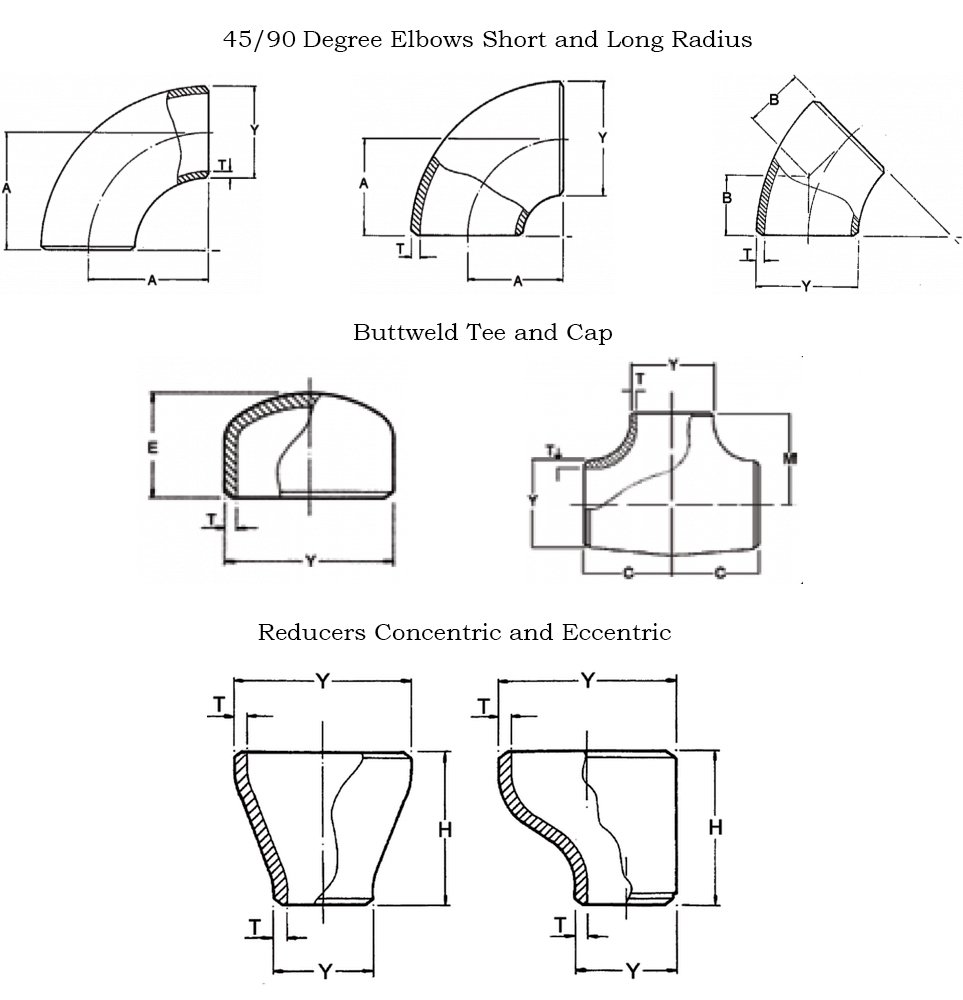

Dimensions Standard Of Stainless Steel 316/ 316L/ 316Ti Buttweld Fittings

| Nominal Pipe Size | Outside Diameter | Caps | Straight Tees | Straight Crosses | Stub Ends | |||

| inch | mm | inch | Length (inch) | Center to End (inch) | Center to End (inch) | Lap Diameter (inch) | Long Length (inch) | Short Length (inch) |

| 1/2 | 21.3 | 0.840 | 1 | 1 | – | 1 3/8 | 3 | 2 |

| 3/4 | 26.7 | 1.050 | 1 | 1 1/8 | – | 1 11/16 | 3 | 2 |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 1/2 | 1 1/2 | 2 | 4 | 2 |

| 1 1/4 | 42.2 | 1.660 | 1 1/2 | 1 7/8 | 1 7/8 | 2 1/2 | 4 | 2 |

| 1 1/2 | 48.3 | 1.900 | 1 1/2 | 2 1/4 | 2 1/4 | 2 7/8 | 4 | 2 |

| 2 | 60.3 | 2.375 | 1 1/2 | 2 1/2 | 2 1/2 | 3 5/8 | 6 | 2 1/2 |

| 2 1/2 | 73.0 | 2.875 | 1 1/2 | 3 | 3 | 4 1/8 | 6 | 2 1/2 |

| 3 | 88.9 | 3.500 | 2 | 3 3/8 | 3 3/8 | 5 | 6 | 2 1/2 |

| 3 1/2 | 101.6 | 4.000 | 2 1/2 | 3 3/4 | 3 3/4 | 5 1/2 | 6 | 3 |

| 4 | 114.3 | 4.500 | 2 1/2 | 4 1/8 | 4 1/8 | 6 3/16 | 6 | 3 |

| 5 | 141.3 | 5.563 | 3 | 4 7/8 | 4 7/8 | 7 5/16 | 8 | 3 |

| 6 | 168.3 | 6.625 | 3 1/2 | 5 5/8 | 5 5/8 | 8 1/2 | 8 | 3 1/2 |

| 8 | 219.1 | 8.625 | 4 | 7 | 7 | 10 5/8 | 8 | 4 |

| 10 | 273.1 | 10.750 | 5 | 8 1/2 | 8 1/2 | 12 3/4 | 10 | 5 |

| 12 | 323.9 | 12.750 | 6 | 10 | 10 | 15 | 10 | 6 |

Size Of Stainless Steel 316/ 316L/ 316Ti Buttweld Fittings

| Product | Size* | Wall Thickness** | Seamless | Welded |

| Elbow | 1/2"-24" | SCH10S~XXS | √ | √ |

| 8"-104" | SCH5S~80S/XS | √ | ||

| Tee | 1/2"-24" | SCH10S~XXS | √ | √ |

| 8"-104" | SCH5S~80S/XS | √ | ||

| Reducer | 1/2"-24" | SCH10S~XXS | √ | √ |

| 8"-104" | SCH5S~80S/XS | √ | ||

| Cap | 1/2"-80" | SCH10S~SCH160 | √ | |

| Lap Joint Stub End | 1/2"-24" | SCH5S~80S/XS | √ | √ |

| 8"-80" | SCH5S~80S/XS | √ |

Weight Chart Of Stainless Steel 316/ 316L/ 316Ti Buttweld Fittings

| DN | Schedule 10S | Schedule 40S | Schedule 80S | ||||||

| 900 Elbow | 450 Elbow | Equal tee | 900 Elbow | 450 Elbow | Equal tee | 900 Elbow | 450 Elbow | Equal tee | |

| 8 | 0.02 | 0.01 | 0.03 | 0.03 | 0.02 | 0.06 | 0.04 | 0.03 | 0.07 |

| 10 | 0.03 | 0.02 | 0.05 | 0.03 | 0.02 | 0.03 | 0.06 | 0.04 | 0.09 |

| 15 | 0.06 | 0.03 | 0.09 | 0.08 | 0.04 | 0.10 | 0.10 | 0.05 | 0.14 |

| 20 | 0.07 | 0.03 | 0.13 | 0.08 | 0.04 | 0.17 | 0.11 | 0.05 | 0.20 |

| 25 | 0.14 | 0.08 | 0.28 | 0.15 | 0.11 | 0.29 | 0.22 | 0.14 | 0.38 |

| 32 | 0.23 | 0.11 | 0.49 | 0.26 | 0.17 | 0.59 | 0.40 | 0.23 | 0.68 |

| 40 | 0.30 | 0.17 | 0.68 | 0.40 | 0.23 | 0.86 | 0.51 | 0.29 | 1.02 |

| 50 | 0.50 | 0.25 | 0.85 | 0.70 | 0.4 | 1.28 | 0.91 | 0.59 | 1.59 |

| 65 | 0.85 | 0.48 | 1.41 | 1.40 | 0.77 | 2.19 | 1.81 | 0.99 | 3.13 |

| 80 | 1.25 | 0.63 | 1.77 | 2.20 | 1.08 | 3.31 | 2.97 | 1.50 | 4.45 |

| 90 | 1.70 | 0.75 | 2.67 | 2.83 | 1.42 | 4.08 | 4.00 | 2.00 | 5.44 |

| 100 | 2.10 | 1.08 | 3.46 | 4.47 | 2.09 | 5.27 | 6.18 | 2.81 | 7.71 |

| 150 | 5.45 | 2.72 | 8.07 | 10.89 | 5.44 | 10.99 | 16.32 | 8.16 | 13.61 |

| 200 | 10.20 | 5.33 | 15.65 | 21.54 | 10.77 | 20.91 | 33.11 | 16.56 | 28.12 |

| 250 | 18.15 | 9.75 | 26.46 | 38.56 | 19.27 | 35.38 | 51.71 | 25.86 | 49.90 |

| 300 | 25.80 | 13.62 | 39.46 | 59.42 | 29.71 | 62.14 | 79.38 | 39.69 | 83.91 |

| DN | Schedule 10S | Schedule 40S | Schedule 80S | ||||||

| Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | |

| 40x.25 | 0.19 | 0.19 | 0.60 | 0.26 | 0.26 | 0.76 | 0.34 | 0.34 | 0.90 |

| 50x25 | 0.28 | 0.28 | 0.73 | 0.40 | 0.40 | 1.10 | 0.54 | 0.54 | 1.37 |

| 50x40 | 0.31 | 0.31 | 0.76 | 0.45 | 0.45 | 1.15 | 0.59 | 0.59 | 1.43 |

| 80x.50 | 0.55 | 0.55 | 1.56 | 1.00 | 1.00 | 2.91 | 1.79 | 1.79 | 3.91 |

| 100x50 | 0.78 | 0.78 | 2.94 | 1.50 | 1.50 | 4.48 | 1.95 | 1.95 | 6.55 |

| 100x80 | 0.87 | 0.87 | 3.04 | 1.74 | 1.74 | 4.64 | 2.33 | 2.33 | 6.79 |

| 150x80 | 1.82 | 1.82 | 6.86 | 3.95 | 3.95 | 9.68 | 5.51 | 5.51 | 11.57 |

| 150x100 | 1.96 | 1.96 | 7.10 | 4.07 | 4.07 | 11.94 | 5.96 | 5.96 | 11.97 |

| 200x100 | 3.01 | 3.01 | 13.46 | 6.55 | 6.55 | 17.98 | 9.23 | 9.23 | 24.18 |

| 200x150 | 3.19 | 3.19 | 14.08 | 6.74 | 6.74 | 18.82 | 10.12 | 10.12 | 25.31 |

Pressure Rating Of Stainless Steel 316/ 316L/ 316Ti Buttweld Fittings

| (oF) | (oC) | 150 |

| -20 to 150 | -29 to 66 | 300 |

| 200 | 93 | 265 |

| 250 | 121 | 225 |

| 300 | 149 | 185 |

| 350 | 177 | 150 |

| 400 | 204 | - |

| 450 | 232 | - |

| 500 | 260 | - |

| 550 | 288 | - |

industrial use fitting for Stainless Steel 316/ 316L/ 316Ti Buttweld Fittings

Price Of Stainless Steel 316/ 316L/ 316Ti Buttweld Fittings

| Stainless Steel Elbow | USD $2.06 - $10.07 / Piece (FOB Price) on request |

| Stainless Steel Equal Tee | USD $2.06 - $10.07 / Piece (FOB Price) on request |

| Stainless Steel Reducing Tee | USD $2.06 - $10.07 / Piece (FOB Price) on request |

| Stainless Steel Cross | USD $2.06 - $10.07 / Piece (FOB Price) on request |

| Stainless Steel Cap | USD $2.06 - $10.07 / Piece (FOB Price) on request |

Application Of Stainless Steel 316/ 316L/ 316Ti Buttweld Fittings

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Stainless Steel 316/ 316L/ 316Ti Buttweld Fittings

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

Packing Of Stainless Steel 316/ 316L/ 316Ti Buttweld Fittings

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

Stainless Steel Buttweld Fittings

- Stainless Steel 304/ 304L/ 304H Buttweld Fittings

- Stainless Steel 309 Buttweld Fittings

- Stainless Steel 310/ 310S Buttweld Fittings

- Stainless Steel 316/ 316L/ 316Ti Buttweld Fittings

- Stainless Steel 321 Buttweld Fittings

- Stainless Steel 347/ 347H Buttweld Fittings

- Stainless Steel 904L Buttweld Fittings

- Stainless Steel 15-5 PH Buttweld Fittings

- Stainless Steel 17-4 PH Buttweld Fittings