Slip On Flange

DIN 1.4301 Slip On Flange, Inconel 625 Slip On Flange, UNS S30400 Slip On Flange, Duplex 31803 Slip On Flange, WRN 2.4856 Slip On Flange, UNS N06625 Slip On Flange, 2507 Super Duplex Slip On Flange.

About Slip On Flange

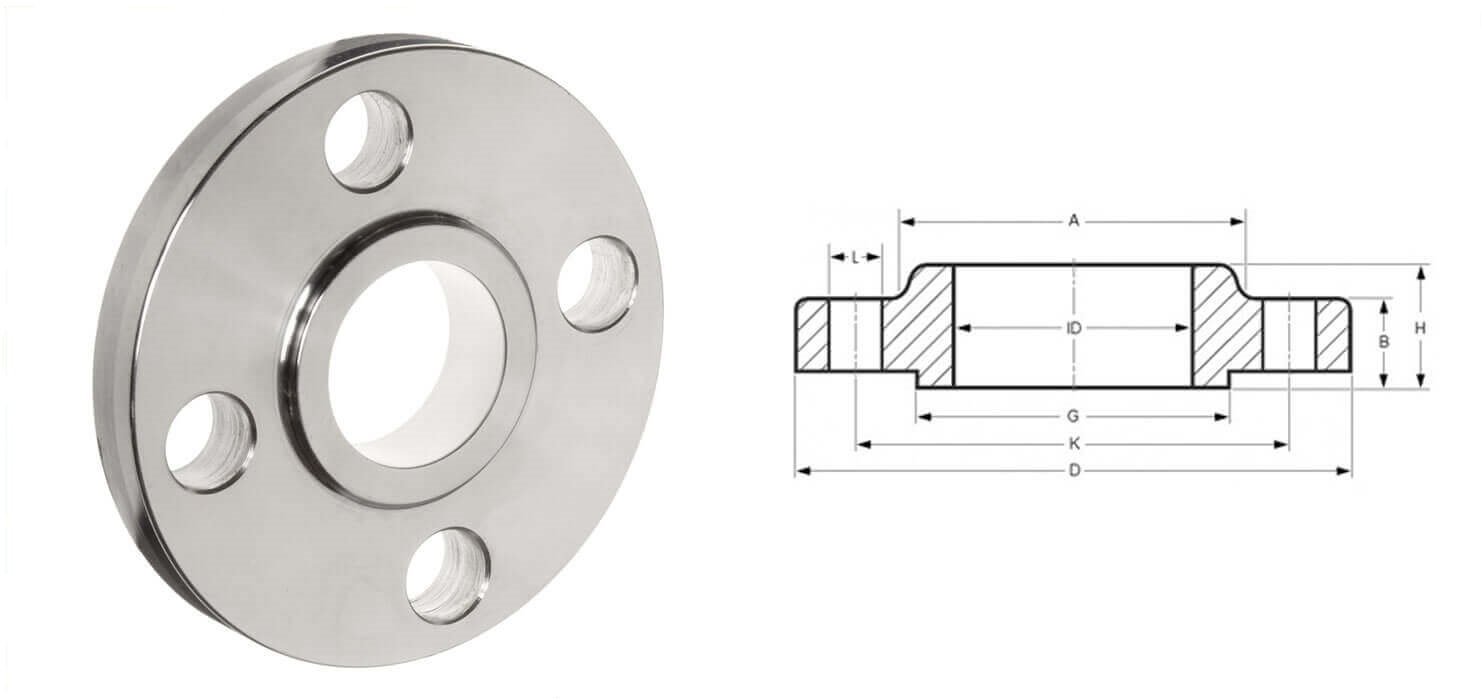

Slip-on flanges are a crucial part of piping systems and are widely utilized in many industries because they are simple to install. A slip-on flange is a type of flange that attaches securely by sliding over the end of a pipe or fitting. Its structure is a circular plate with an exposed hub that fits over the pipe’s outside diameter. The pipe is then joined securely to the flange via welding.

Numerous industries use slip-on flanges, including petrochemical, oil and gas, water treatment, pharmaceuticals, and more. They are frequently employed in non-critical, low-pressure applications such as low-temperature pipelines, ventilation, and water supply systems.

Simple Installation: Slip-on flanges are well-liked because they are easy to install. They are a time-saving solution because their slip-on construction does not require exact alignment during installation.

Cost-effective: These flanges are frequently more affordable than other varieties, making them a sensible option for many jobs.

Versatility: Slip-on flanges are compatible with various pipe systems due to their availability in a wide range of sizes, materials, and pressure ratings.

Even though slip-on flanges provide several advantages, there are a few things to take into account:

Limited Pressure Ratings: Slip-on flanges are inappropriate for systems that often disassemble and reassemble or for high-pressure applications.

Alignment: For a leak-free junction during welding, proper alignment is essential. The integrity of the junction may be compromised if the flange and pipe are not perfectly aligned.

Support and Stability: Slip-on flanges sometimes need extra stability to avoid excessive joint stress, especially when the pipe moves around a lot or vibrates a lot.

A dependable and affordable method of connecting pipes in low-pressure systems is to use slip-on flanges. They are popular in many industries because of their simple installation method and adaptability. When choosing slip-on flanges for a given application, it is crucial to consider the pressure ratings, alignment, and support needs.

UNS S30400 Slip On Flange Manufacturer, ASME SA182 SS 316 Slip On Flange Supplier, DIN 1.4301 Slip On Flange Stockist, Hastelloy C276 Slip On Flange Stockist.

Specification of Slip On Flange

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Slip On Flange |

| Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Slip On Flange |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar Slip On Flange |

| JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K Slip On Flange |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized Slip On Flange |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar Slip On Flange |

| Most common types of Slip On Flange | Forged / Threaded / Screwed / Plate |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

Dimensions Standard Of Slip On Flange

Class 150 Slip On Flange Dimensions

| FLANGE NPS | Inside Diameter | Outside Diameter | Bolt Circle (BC) | Raised Face (R) | Raised Face (RF) | H | Raised Face Thickness (T) | T1 | Flat Face Thickness (T2) | Bolt Hole (B) | No. of Bolt Holes |

| 1/2 | 0.88 | 3.50 | 2.38 | 1.38 | .063 | 1.19 | .62 | .38 | .56 | .62 | 4 |

| 3/4 | 1.09 | 3.88 | 2.75 | 1.69 | .063 | 1.50 | .62 | .44 | .56 | .62 | 4 |

| 1 | 1.36 | 4.25 | 3.12 | 2.00 | .063 | 1.94 | .69 | .50 | .63 | .62 | 4 |

| 1-1/4 | 1.70 | 4.62 | 3.50 | 2.50 | .063 | 2.31 | .81 | .56 | .75 | .62 | 4 |

| 1-1/2 | 1.97 | 5.00 | 3.88 | 2.88 | .063 | 2.56 | .88 | .62 | .82 | .62 | 4 |

| 2 | 2.44 | 6.00 | 4.75 | 3.62 | .063 | 3.06 | 1.00 | .69 | .94 | .75 | 4 |

| 2-1/2 | 2.94 | 7.00 | 5.50 | 4.12 | .063 | 3.56 | 1.12 | .82 | 1.06 | .75 | 4 |

| 3 | 3.57 | 7.50 | 6.00 | 5.00 | .063 | 4.25 | 1.19 | .88 | 1.13 | .75 | 4 |

| 3-1/2 | 4.07 | 8.50 | 7.00 | 5.50 | .063 | 4.81 | 1.25 | .88 | 1.19 | .75 | 8 |

| 4 | 4.57 | 9.00 | 7.50 | 6.19 | .063 | 5.31 | 1.31 | .88 | 1.25 | .75 | 8 |

| 5 | 5.66 | 10.00 | 8.50 | 7.31 | .063 | 6.44 | 1.44 | .88 | 1.38 | .88 | 8 |

| 6 | 6.72 | 11.00 | 9.50 | 8.50 | .063 | 7.56 | 1.56 | .94 | 1.50 | .88 | 8 |

| 8 | 8.72 | 13.50 | 11.75 | 10.62 | .063 | 9.69 | 1.75 | 1.06 | 1.69 | .88 | 8 |

| 10 | 10.88 | 16.00 | 14.25 | 12.75 | .063 | 12.00 | 1.94 | 1.13 | 1.88 | 1.00 | 12 |

| 12 | 12.88 | 19.00 | 17.00 | 15.00 | .063 | 14.38 | 2.19 | 1.19 | 2.13 | 1.00 | 12 |

| 14 | 14.14 | 21.00 | 18.75 | 16.25 | .063 | 15.75 | 2.25 | 1.32 | 2.19 | 1.12 | 12 |

| 16 | 16.16 | 23.50 | 21.25 | 18.50 | .063 | 18.00 | 2.50 | 1.38 | 2.44 | 1.12 | 16 |

| 18 | 18.18 | 25.00 | 22.75 | 21.00 | .063 | 19.88 | 2.69 | 1.50 | 2.63 | 1.25 | 16 |

| 20 | 20.20 | 27.50 | 25.00 | 23.00 | .063 | 22.00 | 2.88 | 1.63 | 2.83 | 1.25 | 20 |

| 22 | 22.22 | 29.50 | 27.25 | 25.25 | .063 | 24.25 | 3.13 | 1.75 | 3.07 | 1.38 | 20 |

| 24 | 24.25 | 32.00 | 29.50 | 27.25 | .063 | 26.12 | 3.25 | 1.82 | 3.19 | 1.38 | 20 |

Class 300 Slip On Flange Dimensions

| FLANGE NPS | Inside Diameter | Outside Diameter | Bolt Circle (BC) | Raised Face (R) | Raised Face (RF) | H | Raised Face Thickness (T) | T1 | Flat Face Thickness (T2) | Bolt Hole (B) | No. of Bolt Holes |

| 1/2 | 0.88 | 3.75 | 2.62 | 1.38 | .063 | 1.50 | 0.88 | 0.50 | 0.82 | 0.62 | 4 |

| 3/4 | 1.09 | 4.62 | 3.25 | 1.69 | .063 | 1.88 | 1.00 | .056 | 0.94 | 0.75 | 4 |

| 1 | 1.36 | 4.88 | 3.50 | 2.00 | .063 | 2.12 | 1.06 | 0.63 | 1.00 | 0.75 | 4 |

| 1-1/4 | 1.70 | 5.25 | 3.88 | 2.50 | .063 | 2.50 | 1.06 | 0.69 | 1.00 | 0.75 | 4 |

| 1-1/2 | 1.95 | 6.12 | 4.50 | 2.88 | .063 | 2.75 | 1.19 | 0.75 | 1.13 | 0.88 | 4 |

| 2 | 2.44 | 6.50 | 5.00 | 3.62 | .063 | 3.31 | 1.31 | 0.82 | 1.25 | 0.75 | 8 |

| 2-1/2 | 2.94 | 7.50 | 5.88 | 4.12 | .063 | 3.94 | 1.50 | 0.94 | 1.44 | 0.88 | 8 |

| 3 | 3.57 | 8.25 | 6.62 | 5.00 | .063 | 4.62 | 1.69 | 1.06 | 1.63 | 0.88 | 8 |

| 3-1/2 | 4.07 | 9.00 | 7.25 | 5.50 | .063 | 5.25 | 1.75 | 1.13 | 1.69 | 0.88 | 8 |

| 4 | 4.57 | 10.00 | 7.88 | 6.19 | .063 | 5.75 | 1.88 | 1.19 | 1.82 | 0.88 | 8 |

| 5 | 5.66 | 11.00 | 9.25 | 7.31 | .063 | 7.00 | 2.00 | 1.32 | 1.94 | 0.88 | 8 |

| 6 | 6.72 | 12.50 | 10.62 | 8.50 | .063 | 8.12 | 2.06 | 1.38 | 2.00 | 0.88 | 12 |

| 8 | 8.72 | 15.00 | 13.00 | 10.62 | .063 | 10.25 | 2.44 | 1.56 | 2.38 | 1.00 | 12 |

| 10 | 10.88 | 17.50 | 15.25 | 12.75 | .063 | 12.62 | 2.62 | 1.82 | 2.56 | 1.12 | 16 |

| 12 | 12.88 | 20.50 | 17.75 | 15.00 | .063 | 14.75 | 2.88 | 1.94 | 2.82 | 1.25 | 16 |

| 14 | 14.14 | 23.00 | 20.25 | 16.25 | .063 | 16.75 | 3.00 | 2.06 | 2.94 | 1.25 | 20 |

| 16 | 16.16 | 25.50 | 22.50 | 18.50 | .063 | 19.00 | 3.25 | 2.19 | 3.19 | 1.38 | 20 |

| 18 | 18.18 | 28.00 | 24.75 | 21.00 | .063 | 21.00 | 3.50 | 2.32 | 3.44 | 1.38 | 24 |

| 20 | 20.20 | 30.50 | 27.00 | 23.00 | .063 | 23.12 | 3.75 | 2.44 | 3.69 | 1.38 | 24 |

| 22 | 22.22 | 33.00 | 29.25 | 25.25 | .063 | 25.25 | 4.00 | 2.57 | 3.94 | 1.63 | 24 |

| 24 | 24.25 | 36.00 | 32.00 | 27.25 | .063 | 27.62 | 4.19 | 2.69 | 4.13 | 1.62 | 24 |

Class 400 Slip On Flange Dimensions

| FLANGE NPS | Inside Diameter | Outside Diameter | Bolt Circle (BC) | Raised Face (R) | Raised Face (RF) | H | Raised Face Thickness (T) | T1 | Flat Face Thickness (T2) | Bolt Hole (B) | No. of Bolt Holes |

| 1/2 | 0.88 | 3.75 | 2.62 | 1.38 | .250 | 1.50 | 1.13 | 0.56 | 0.88 | 0.62 | 4 |

| 3/4 | 1.09 | 4.62 | 3.25 | 1.69 | .250 | 1.88 | 1.25 | 0.62 | 1.00 | 0.75 | 4 |

| 1 | 1.36 | 4.88 | 3.50 | 2.00 | .250 | 2.12 | 1.31 | 0.69 | 1.06 | 0.75 | 4 |

| 1-1/4 | 1.70 | 5.25 | 3.88 | 2.50 | .250 | 2.50 | 1.37 | 0.81 | 1.12 | 0.75 | 4 |

| 1-1/2 | 1.95 | 6.12 | 4.50 | 2.88 | .250 | 2.75 | 1.50 | 0.88 | 1.25 | 0.88 | 4 |

| 2 | 2.44 | 6.50 | 5.00 | 3.62 | .250 | 3.31 | 1.69 | 1.00 | 1.44 | 0.75 | 8 |

| 2-1/2 | 2.94 | 7.50 | 5.88 | 4.12 | .250 | 3.94 | 1.87 | 1.12 | 1.62 | 0.88 | 8 |

| 3 | 3.57 | 8.25 | 6.62 | 5.00 | .250 | 4.62 | 2.06 | 1.25 | 1.81 | 0.88 | 8 |

| 3-1/2 | 4.07 | 9.00 | 7.25 | 5.50 | .250 | 5.25 | 2.19 | 1.38 | 1.94 | 1.00 | 8 |

| 4 | 4.57 | 10.00 | 7.88 | 6.19 | .250 | 5.75 | 2.25 | 1.38 | 2.00 | 1.00 | 8 |

| 5 | 5.66 | 11.00 | 9.25 | 7.31 | .250 | 7.00 | 2.37 | 1.50 | 2.12 | 1.00 | 8 |

| 6 | 6.72 | 12.50 | 10.62 | 8.50 | .250 | 8.12 | 2.50 | 1.62 | 2.25 | 1.00 | 12 |

| 8 | 8.72 | 15.00 | 13.00 | 10.62 | .250 | 10.25 | 2.94 | 1.88 | 2.69 | 1.12 | 12 |

| 10 | 10.88 | 17.50 | 15.25 | 12.75 | .250 | 12.62 | 3.13 | 2.12 | 2.88 | 1.25 | 16 |

| 12 | 12.88 | 20.50 | 17.75 | 15.00 | .250 | 14.75 | 3.37 | 2.25 | 3.12 | 1.38 | 16 |

| 14 | 14.14 | 23.00 | 20.25 | 16.25 | .250 | 16.75 | 3.56 | 2.38 | 3.31 | 1.38 | 20 |

| 16 | 16.16 | 25.50 | 22.50 | 18.50 | .250 | 19.00 | 3.94 | 2.50 | 3.69 | 1.50 | 20 |

| 18 | 18.18 | 28.00 | 24.75 | 21.00 | .250 | 21.00 | 4.13 | 2.62 | 3.88 | 1.50 | 24 |

| 20 | 20.20 | 30.50 | 27.00 | 23.00 | .250 | 23.12 | 4.25 | 2.75 | 4.00 | 1.62 | 24 |

| 22 | 22.22 | 33.00 | 29.25 | 25.25 | .250 | 25.25 | 4.50 | 2.88 | 4.25 | 1.75 | 24 |

| 24 | 24.25 | 36.00 | 32.00 | 27.25 | .250 | 27.62 | 4.75 | 3.00 | 4.50 | 1.88 | 24 |

Class 600 Slip On Flange Dimensions

| FLANGE NPS | Inside Diameter | Outside Diameter | Bolt Circle (BC) | Raised Face (R) | Raised Face (RF) | H | Raised Face Thickness (T) | T1 | Flat Face Thickness (T2) | Bolt Hole (B) | No. of Bolt Holes |

| 1/2 | 0.88 | 3.75 | 2.62 | 1.38 | .250 | 1.50 | 1.13 | 0.56 | 0.88 | 0.62 | 4 |

| 3/4 | 1.09 | 4.62 | 3.25 | 1.69 | .250 | 1.88 | 1.25 | 0.62 | 1.00 | 0.75 | 4 |

| 1 | 1.36 | 4.88 | 3.50 | 2.00 | .250 | 2.12 | 1.31 | 0.69 | 1.06 | 0.75 | 4 |

| 1-1/4 | 1.7 | 5.25 | 3.88 | 2.50 | .250 | 2.50 | 1.37 | 0.81 | 1.12 | 0.75 | 4 |

| 1-1/2 | 1.95 | 6.12 | 4.50 | 2.88 | .250 | 2.75 | 1.50 | 0.88 | 1.25 | 0.88 | 4 |

| 2 | 2.44 | 6.50 | 5.00 | 3.62 | .250 | 3.31 | 1.69 | 1.00 | 1.44 | 0.75 | 8 |

| 2-1/2 | 2.94 | 7.50 | 5.88 | 4.12 | .250 | 3.94 | 1.87 | 1.12 | 1.62 | 0.88 | 8 |

| 3 | 3.57 | 8.25 | 6.62 | 5.00 | .250 | 4.62 | 2.06 | 1.25 | 1.81 | 0.88 | 8 |

| 3-1/2 | 4.07 | 9.00 | 7.25 | 5.50 | .250 | 5.25 | 2.19 | 1.38 | 1.94 | 1.00 | 8 |

| 4 | 4.57 | 10.75 | 8.50 | 6.19 | .250 | 6.00 | 2.37 | 1.5 | 2.12 | 1.00 | 8 |

| 5 | 5.66 | 13.00 | 10.50 | 7.31 | .250 | 7.44 | 2.63 | 1.75 | 2.38 | 1.12 | 8 |

| 6 | 6.72 | 14.00 | 11.50 | 8.50 | .250 | 8.75 | 2.87 | 1.88 | 2.62 | 1.12 | 12 |

| 8 | 8.72 | 16.50 | 13.75 | 10.62 | .250 | 10.75 | 3.25 | 2.19 | 3.00 | 1.25 | 12 |

| 10 | 10.88 | 20.00 | 17.00 | 12.75 | .250 | 13.5 | 3.63 | 2.50 | 3.38 | 1.38 | 16 |

| 12 | 12.88 | 22.00 | 19.25 | 15.00 | .250 | 15.75 | 3.87 | 2.62 | 3.62 | 1.38 | 20 |

| 14 | 14.14 | 23.75 | 20.75 | 16.25 | .250 | 17.00 | 3.94 | 2.75 | 3.69 | 1.50 | 20 |

| 16 | 16.16 | 27.00 | 23.75 | 18.50 | .250 | 19.50 | 4.44 | 3.00 | 4.19 | 1.62 | 20 |

| 18 | 18.18 | 29.25 | 25.75 | 21.00 | .250 | 21.50 | 4.87 | 3.25 | 4.62 | 1.75 | 20 |

| 20 | 20.20 | 32.00 | 28.50 | 23.00 | .250 | 24.00 | 5.25 | 3.50 | 5.00 | 1.75 | 24 |

| 22 | 22.22 | 34.25 | 30.63 | 25.25 | .250 | 26.25 | 5.50 | 3.75 | 5.25 | 1.75 | 24 |

| 24 | 24.25 | 37.00 | 33.00 | 27.25 | .250 | 28.25 | 5.75 | 4.00 | 5.50 | 2.00 | 24 |

Class 900 Slip On Flanges Dimensions

| FLANGE NPS | Inside Diameter | Outside Diameter | Bolt Circle (BC) | Raised Face (R) | Raised Face (RF) | H | Raised Face Thickness (T) | T1 | Flat Face Thickness (T2) | Bolt Hole (B) | No. of Bolt Holes |

| 3 | 3.57 | 9.50 | 7.50 | 5.00 | .250 | 5.00 | 2.38 | 1.50 | 2.13 | 1.00 | 8 |

| 4 | 4.57 | 11.50 | 9.25 | 6.19 | .250 | 6.25 | 3.00 | 1.75 | 2.75 | 1.25 | 8 |

| 5 | 5.66 | 13.75 | 11.00 | 7.31 | .250 | 7.50 | 3.38 | 3.00 | 3.13 | 1.38 | 8 |

| 6 | 6.72 | 15.00 | 12.50 | 8.50 | .250 | 9.25 | 3.63 | 2.19 | 3.38 | 1.25 | 12 |

| 8 | 8.72 | 18.50 | 15.50 | 10.63 | .250 | 11.75 | 4.25 | 2.50 | 4.00 | 1.50 | 12 |

| 10 | 10.88 | 21.50 | 18.50 | 12.75 | .250 | 14.50 | 4.50 | 2.75 | 4.25 | 1.50 | 16 |

| 12 | 12.88 | 24.00 | 21.00 | 15.00 | .250 | 16.50 | 4.88 | 3.13 | 4.63 | 1.50 | 20 |

| 14 | 14.14 | 25.25 | 22.00 | 16.25 | .250 | 17.75 | 5.38 | 3.38 | 5.13 | 1.63 | 20 |

| 16 | 16.16 | 27.75 | 24.25 | 18.50 | .250 | 20.00 | 5.50 | 3.50 | 5.25 | 1.75 | 20 |

| 18 | 18.18 | 31.00 | 27.00 | 21.00 | .250 | 22.25 | 6.25 | 4.00 | 6.00 | 2.00 | 20 |

| 20 | 20.20 | 33.75 | 29.50 | 23.00 | .250 | 24.50 | 6.50 | 4.25 | 6.25 | 2.13 | 20 |

| 24 | 24.25 | 41.00 | 35.50 | 27.25 | .250 | 29.50 | 8.25 | 5.50 | 8.00 | 2.63 | 20 |

Class 1500 Slip On Flanges Dimensions

| FLANGE NPS | Inside Diameter | OD | Bolt Circle (BC) | Raised Face (R) | Raised Face (RF) | H | Raised Face Thickness (T) | T1 | Flat Face Thickness (T2) | Bolt Hole (B) | No. of Bolt Holes |

| 1/2 | 0.88 | 4.75 | 3.25 | 1.38 | .250 | 1.50 | 1.50 | 0.88 | 1.25 | 0.88 | 4 |

| 3/4 | 1.09 | 5.13 | 3.50 | 1.69 | .250 | 1.75 | 1.63 | 1.00 | 1.38 | 0.88 | 4 |

| 1 | 1.36 | 5.88 | 4.00 | 2.00 | .250 | 2.06 | 1.88 | 1.13 | 1.63 | 1.00 | 4 |

| 1-1/4 | 1.70 | 6.25 | 4.38 | 2.50 | .250 | 2.50 | 1.88 | 1.13 | 1.63 | 1.00 | 4 |

| 1-1/2 | 1.95 | 7.00 | 4.88 | 2.88 | .250 | 2.75 | 2.00 | 1.25 | 1.75 | 1.13 | 4 |

| 2 | 2.44 | 8.50 | 6.50 | 3.63 | .250 | 4.13 | 2.50 | 1.50 | 2.25 | 1.00 | 8 |

| 2-1/2 | 2.94 | 9.63 | 7.50 | 4.13 | .250 | 4.88 | 2.75 | 1.63 | 2.50 | 1.13 | 8 |

| 3 ** | 3.57 | 10.50 | 8.00 | 5.00 | .250 | 5.25 | 3.13 | 1.88 | 2.88 | 1.25 | 8 |

| 4 ** | 4.57 | 12.25 | 9.50 | 6.19 | .250 | 6.38 | 3.81 | 2.13 | 3.56 | 1.38 | 8 |

| 5 ** | 5.66 | 14.75 | 11.50 | 7.31 | .250 | 7.75 | 4.38 | 2.88 | 4.13 | 1.63 | 8 |

| 6 ** | 6.72 | 15.50 | 12.50 | 8.50 | .250 | 9.00 | 4.94 | 3.25 | 4.69 | 1.50 | 12 |

| 8 ** | 8.72 | 19.00 | 15.50 | 10.63 | .250 | 11.50 | 5.88 | 3.63 | 5.63 | 1.75 | 12 |

| 10 ** | 10.88 | 23.00 | 19.00 | 12.75 | .250 | 14.50 | 6.50 | 4.25 | 6.25 | 2.00 | 12 |

| 12 ** | 12.88 | 26.50 | 22.50 | 15.00 | .250 | 17.75 | 7.38 | 4.88 | 7.13 | 2.13 | 16 |

Class 2500 Slip On Flanges Dimensions

| FLANGE NPS | Inside Diameter | Outside Diameter | Bolt Circle (BC) | Raised Face (R) | Raised Face (RF) | H | Raised Face Thickness (T) | T1 | Flat Face Thickness (T2) | Bolt Hole (B) | No. of Bolt Holes |

| 1/2 | 0.88 | 5.25 | 3.50 | 1.38 | .250 | 1.69 | 1.81 | 1.19 | 1.56 | 0.88 | 4 |

| 3/4 | 1.09 | 5.50 | 3.75 | 1.69 | .250 | 2.00 | 1.94 | 1.25 | 1.69 | 0.88 | 4 |

| 1 | 1.36 | 6.25 | 4.25 | 2.00 | .250 | 2.25 | 2.13 | 1.38 | 1.88 | 1.00 | 4 |

| 1-1/4 | 1.70 | 7.25 | 5.13 | 2.50 | .250 | 2.88 | 2.31 | 1.50 | 2.06 | 1.13 | 4 |

| 1-1/2 | 1.95 | 8.00 | 5.75 | 2.88 | .250 | 3.13 | 2.63 | 1.75 | 2.38 | 1.25 | 4 |

| 2 | 2.44 | 9.25 | 6.75 | 3.63 | .250 | 3.75 | 3.00 | 2.00 | 2.75 | 1.13 | 8 |

| 2-1/2 | 2.94 | 10.50 | 7.75 | 4.13 | .250 | 4.50 | 3.38 | 2.25 | 3.13 | 1.25 | 8 |

| 3 | 3.57 | 12.00 | 9.00 | 5.00 | .250 | 5.25 | 3.88 | 2.63 | 3.63 | 1.38 | 8 |

| 4 | 4.57 | 14.00 | 10.75 | 6.19 | .250 | 6.50 | 4.50 | 3.00 | 4.25 | 1.63 | 8 |

| 5 | 5.66 | 16.50 | 12.75 | 7.31 | .250 | 8.00 | 5.38 | 3.63 | 5.13 | 1.88 | 8 |

| 6 | 6.72 | 19.00 | 14.50 | 8.50 | .250 | 9.25 | 6.25 | 4.25 | 6.00 | 2.13 | 8 |

| 8 | 8.72 | 21.75 | 17.25 | 10.63 | .250 | 12.00 | 7.25 | 5.00 | 7.00 | 2.13 | 12 |

| 10 | 10.88 | 26.50 | 21.25 | 12.75 | .250 | 14.75 | 9.25 | 6.50 | 9.00 | 2.63 | 12 |

| 12 | 12.88 | 30.00 | 24.38 | 15.00 | .250 | 17.38 | 10.25 | 7.25 | 10.00 | 2.88 | 12 |

Size Of Slip On Flange

| Size | 150 # | 300 # | 600 # | 900 # | 1500 # | 2500 # | ||||||||||||

| WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN |

| 1/2" | 2 | 1 | 1 | 2 | 1 | 1 | 2 | 2 | 2 | SEE 1500 # WEIGHTS | 5 | 4 | 4 | 7 | 7 | 7 | ||

| 3/4" | 2 | 2 | 2 | 3 | 3 | 3 | 4 | 3 | 3 | SEE 1500 # WEIGHTS | 6 | 5 | 6 | 8 | 8 | 8 | ||

| 1" | 3 | 2 | 2 | 4 | 3 | 3 | 4 | 4 | 4 | SEE 1500 # WEIGHTS | 9 | 8 | 8 | 12 | 11 | 11 | ||

| 1 1/2" | 4 | 3 | 3 | 7 | 6 | 6 | 8 | 7 | 8 | SEE 1500 # WEIGHTS | 13 | 12 | 13 | 25 | 22 | 23 | ||

| 2" | 6 | 5 | 5 | 9 | 7 | 8 | 12 | 9 | 10 | SEE 1500 # WEIGHTS | 25 | 25 | 25 | 42 | 37 | 39 | ||

| 2 1/2" | 8 | 7 | 7 | 12 | 10 | 12 | 18 | 13 | 15 | SEE 1500 # WEIGHTS | 36 | 36 | 35 | 52 | 55 | 56 | ||

| 3" | 10 | 8 | 9 | 15 | 13 | 16 | 23 | 16 | 20 | 31 | 26 | 29 | 48 | 48 | 48 | 94 | 83 | 86 |

| 4" | 15 | 13 | 17 | 25 | 22 | 27 | 42 | 37 | 41 | 53 | 53 | 54 | 73 | 73 | 73 | 145 | 125 | 130 |

| 5" | 19 | 15 | 20 | 32 | 28 | 35 | 68 | 63 | 68 | 86 | 83 | 87 | 130 | 130 | 140 | 245 | 210 | 225 |

| 6" | 24 | 19 | 26 | 42 | 39 | 50 | 81 | 80 | 86 | 110 | 110 | 115 | 165 | 165 | 160 | 380 | 325 | 345 |

| 8" | 39 | 30 | 45 | 67 | 58 | 81 | 120 | 115 | 140 | 175 | 170 | 200 | 275 | 260 | 300 | 580 | 485 | 530 |

| 10" | 52 | 43 | 70 | 91 | 81 | 124 | 190 | 170 | 230 | 260 | 245 | 290 | 455 | 435 | 510 | 1075 | 930 | 1025 |

| 12" | 80 | 64 | 110 | 140 | 115 | 185 | 225 | 200 | 295 | 325 | 325 | 415 | 690 | 580 | 690 | 1525 | 1100 | 1300 |

| 14" | 110 | 90 | 140 | 180 | 165 | 250 | 280 | 230 | 355 | 400 | 400 | 520 | 940 | NA | 975 | NA | NA | NA |

| 16" | 140 | 98 | 180 | 250 | 190 | 295 | 390 | 330 | 495 | 495 | 425 | 600 | 1250 | NA | 1300 | NA | NA | NA |

| 18" | 150 | 130 | 220 | 320 | 250 | 395 | 475 | 400 | 630 | 680 | 600 | 850 | 1625 | NA | 1750 | NA | NA | NA |

| 20" | 180 | 165 | 285 | 400 | 315 | 505 | 590 | 510 | 810 | 830 | 730 | 1075 | 2050 | NA | 2225 | NA | NA | NA |

| 22" | 225 | 185 | 355 | 465 | 370 | 640 | 720 | 590 | 1000 | NA | NA | NA | NA | NA | NA | NA | NA | NA |

| 24" | 260 | 220 | 430 | 580 | 475 | 790 | 830 | 730 | 1250 | 1500 | 1400 | 2025 | 3325 | NA | 3625 | NA | NA | NA |

Weight Chart Of Slip On Flange

| Rated Diameter | O.D. of Pipe | Flange Parameter | Neck Size | Size of R.F. | Bolts | Approx. Weight | |||||||

| DN | d1 | D | d5 | b | k | h | d3 | r | d4 | f | No. of holes | d2 | KG |

| 10 | 17.2 | 90 | 17.7 | 14 | 60 | 20 | 30 | 4 | 40 | 2 | 4 | 14 | 0.56 |

| 15 | 21.3 | 95 | 22 | 14 | 65 | 20 | 35 | 4 | 45 | 2 | 4 | 14 | 0.62 |

| 20 | 26.9 | 105 | 27.6 | 16 | 75 | 24 | 45 | 4 | 58 | 2 | 4 | 14 | 0.91 |

| 25 | 33.7 | 115 | 34.4 | 16 | 85 | 24 | 52 | 5 | 68 | 2 | 4 | 14 | 1.09 |

| 32 | 42.4 | 140 | 43.1 | 16 | 100 | 26 | 60 | 5 | 78 | 2 | 4 | 18 | 1.58 |

| 40 | 48.3 | 150 | 49 | 16 | 110 | 26 | 70 | 5 | 88 | 3 | 4 | 18 | 1.76 |

| 50 | 60.3 | 165 | 61.1 | 18 | 125 | 28 | 85 | 5 | 102 | 3 | 4 | 18 | 2.39 |

| 65 | 76.1 | 185 | 77.1 | 18 | 145 | 32 | 105 | 5 | 122 | 3 | 4 | 18 | 3.1 |

| 80 | 88.9 | 200 | 90.3 | 20 | 160 | 34 | 118 | 5 | 138 | 3 | 8 | 18 | 3.77 |

| 100 | 114.3 | 220 | 115.9 | 20 | 180 | 38 | 140 | 5 | 158 | 3 | 8 | 18 | 4.29 |

| 125 | 139.7 | 250 | 141.6 | 22 | 210 | 40 | 168 | 5 | 188 | 3 | 8 | 18 | 5.86 |

| 150 | 168.3 | 285 | 170.5 | 22 | 240 | 44 | 196 | 5 | 212 | 3 | 8 | 22 | 7.22 |

| 175 | 193.7 | 315 | 196.1 | 24 | 270 | 44 | 224 | 6 | 242 | 3 | 8 | 22 | 9.18 |

| 200 | 219.4 | 340 | 222 | 24 | 295 | 44 | 247 | 6 | 268 | 3 | 8 | 22 | 9.95 |

| 250 | 273 | 395 | 276 | 26 | 350 | 46 | 300 | 6 | 320 | 3 | 12 | 22 | 12.69 |

| 300 | 323.9 | 445 | 327 | 26 | 400 | 46 | 352 | 6 | 370 | 4 | 12 | 22 | 14.4 |

| 350 | 355.6 | 505 | 359 | 26 | 460 | 53 | 398 | 10 | 430 | 4 | 16 | 22 | 22.36 |

| 400 | 406.4 | 565 | 410 | 26 | 515 | 57 | 448 | 10 | 482 | 4 | 16 | 26 | 26.85 |

| 450 | 457 | 615 | 461 | 28 | 565 | 62 | 502 | 10 | 532 | 4 | 20 | 26 | 32.53 |

| 500 | 508 | 670 | 512 | 28 | 620 | 67 | 552 | 10 | 585 | 4 | 20 | 26 | 37.84 |

| 600 | 610 | 780 | 614 | 28 | 725 | 75 | 658 | 10 | 685 | 5 | 20 | 30 | 49.32 |

| 700 | 711 | 895 | 716 | 30 | 840 | 77 | 760 | 10 | 800 | 5 | 24 | 30 | 63.86 |

| 800 | 813 | 1015 | 818 | 32 | 950 | 84 | 864 | 10 | 905 | 5 | 24 | 33 | 85.19 |

| 900 | 914 | 1115 | 920 | 34 | 1050 | 88 | 969 | 10 | 1005 | 5 | 28 | 33 | 101.4 |

| 1000 | 1016 | 1230 | 1022 | 34 | 1160 | 92 | 1071 | 10 | 1110 | 5 | 28 | 36 | 119.7 |

Pressure Rating Of Slip On Flange

Pressure-Temperature Ratings for ASTM Group 2-1.1 Materials

Working pressure by Classes, BAR

| Temp -29 °C | 150 | 300 | 400 | 600 | 900 | 1500 | 2500 |

| 38 | 19.6 | 51.1 | 68.1 | 102.1 | 153.2 | 255.3 | 425.5 |

| 50 | 19.2 | 50.1 | 66.8 | 100.2 | 150.4 | 250.6 | 417.7 |

| 100 | 17.7 | 46.6 | 62.1 | 93.2 | 139.8 | 233 | 388.3 |

| 150 | 15.8 | 45.1 | 60.1 | 90.2 | 135.2 | 225.4 | 375.6 |

| 200 | 13.8 | 43.8 | 58.4 | 87.6 | 131.4 | 219 | 365 |

| 250 | 12.1 | 41.9 | 55.9 | 83.9 | 125.8 | 209.7 | 349.5 |

| 300 | 10.2 | 39.8 | 53.1 | 79.6 | 119.5 | 199.1 | 331.8 |

| 325 | 9.3 | 38.7 | 51.6 | 77.4 | 116.1 | 193.6 | 322.6 |

| 350 | 8.4 | 37.6 | 50.1 | 75.1 | 112.7 | 187.8 | 313 |

| 375 | 7.4 | 36.4 | 48.5 | 72.7 | 109.1 | 181.8 | 303.1 |

| 400 | 6.5 | 34.7 | 46.3 | 69.4 | 104.2 | 173.6 | 289.3 |

| 425 | 5.5 | 28.8 | 38.4 | 57.5 | 86.3 | 143.8 | 239.7 |

| 450 | 4.6 | 23 | 30.7 | 46 | 69 | 115 | 191.7 |

| 475 | 3.7 | 17.4 | 23.2 | 34.9 | 52.3 | 87.2 | 145.3 |

| 500 | 2.8 | 11.8 | 15.7 | 23.5 | 35.3 | 58.8 | 97.9 |

| 538 | 1.4 | 5.9 | 7.9 | 11.8 | 17.7 | 29.5 | 49.2 |

| Temp °C | 150 | 300 | 400 | 600 | 900 | 1500 | 2500 |

Pressure-Temperature Ratings for ASTM Group 2-2.3 Materials

Working pressure by Classes, BAR

| Temp -29 °C | 150 | 300 | 400 | 600 | 900 | 1500 | 2500 |

| 38 | 15.9 | 41.4 | 55.2 | 82.7 | 124.1 | 206.8 | 344.7 |

| 50 | 15.3 | 40 | 53.4 | 80 | 120.1 | 200.1 | 333.5 |

| 100 | 13.3 | 34.8 | 46.4 | 69.6 | 104.4 | 173.9 | 289.9 |

| 150 | 12 | 31.4 | 41.9 | 62.8 | 94.2 | 157 | 261.6 |

| 200 | 11.2 | 29.2 | 38.9 | 58.3 | 87.5 | 145.8 | 243 |

| 250 | 10.5 | 27.5 | 36.6 | 54.9 | 82.4 | 137.3 | 228.9 |

| 300 | 10 | 26.1 | 34.8 | 52.1 | 78.2 | 130.3 | 217.2 |

| 325 | 9.3 | 25.5 | 34 | 51 | 76.4 | 127.4 | 212.3 |

| 350 | 8.4 | 25.1 | 33.4 | 50.1 | 75.2 | 125.4 | 208.9 |

| 375 | 7.4 | 24.8 | 33 | 49.5 | 74.3 | 123.8 | 206.3 |

| 400 | 6.5 | 24.3 | 32.4 | 48.6 | 72.9 | 121.5 | 202.5 |

| 425 | 5.5 | 23.9 | 31.8 | 47.7 | 71.6 | 119.3 | 198.8 |

| 450 | 4.6 | 23.4 | 31.2 | 46.8 | 70.2 | 117.1 | 195.1 |

| Temp °C | 150 | 300 | 400 | 600 | 900 | 1500 | 2500 |

Price Of Slip On Flange

| Stainless Steel Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| High Nickel Alloys Flanges | USD $8.10 - $20.20 / Piece (FOB Price) on request |

| Duplex & Super Duplex Flange | USD $10.20 - $35.50 / Piece (FOB Price) on request |

| Cupro Nickel Flanges | USD $5.19 - $10.48 / Piece (FOB Price) on request |

| Carbon Steel Flanges | USD $2.08 - $7.10 / Piece (FOB Price) on request |

Application Of Slip On Flange

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Slip On Flange

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

Packing Of Slip On Flange

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

Hastelloy C276 Slip On Flange Price List, UNS N06625 Slip On Flange Weight Chart, UNS N08904 Slip On Flange Weight Calculator, UNS S30400 Slip On Flange Price List In India, DIN 1.4301 Slip On Flange Catalogue, ASME SA182 Duplex 2205 Slip On Flange At Factory Price, ASTM A182 SS 304 Slip On Flange Weight Chart, Inconel 625 Slip On Flange At Factory Price, 2507 Super Duplex Slip On Flange At Factory Price, ASME SA182 SS 316 Slip On Flange Price Per Kg.

UNS N08904 Slip On Flange Supplier in Hyderabad, Inconel 625 Slip On Flange Supplier in Hyderabad, ASME SA182 Duplex 2205 Slip On Flange Stockist in Chennai, DIN 1.4301 Slip On Flange Stockist in Ahmedabad, UNS S30400 Slip On Flange Manufacturer in Mumbai, Hastelloy C276 Slip On Flange Stockist in Pimpri-Chinchwad, UNS N06625 Slip On Flange Stockist in Bangalore, ASME SA182 SS 316 Slip On Flange Supplier in Coimbatore, 2507 Super Duplex Slip On Flange Supplier in Pune.

ASME SA182 Duplex 2205 Slip On Flange Stockist in UAE, WRN 2.4856 Slip On Flange Manufacturer in Vietnam, Duplex 31803 Slip On Flange Stockist in Oman, UNS N08904 Slip On Flange Exporter in Kuwait, UNS N06625 Slip On Flange Exporter in South Africa, UNS S30400 Slip On Flange Manufacturer in Singapore, 304 Stainless Steel Slip On Flange Stockist in Australia, DIN 1.4301 Slip On Flange Stockist in Malaysia, Inconel 625 Slip On Flange Exporter in Indonesia, 2507 Super Duplex Slip On Flange Supplier in Qatar.

Types of Flanges

- Forge Flange

- Blind Flange

- Slip On Flange

- Weldneck Flange

- Lap Joint Flange

- Threaded Flange

- Socketweld Flange

- Long Weld Neck Flange

- Weldo / Nipo Flange

- Orifice Flange

- Reducing Flange

- Flat Flange

- Loose Flange

- RTJ Flanges

- SORF Flanges

- Square Flanges

- SWRF Flanges

- Expander Flanges

- WNRF Flanges

- Ring Type Joint Flanges

- Groove & Tongue Flanges

- Spectacle Blind Flanges

- Weld Neck Flanges A / B Flanges

- Spades Ring Spacers Flanges

- Screwed Flanges

- Forging Facing Flanges

- Flanges Bolts