Weldneck Flanges

UNS S30400 Weldneck Flanges, DIN 1.4301 Weldneck Flanges, UNS N08904 Weldneck Flanges, ASME SA182 Duplex 2205 Weldneck Flanges, ASME SA182 SS 316 Weldneck Flanges.

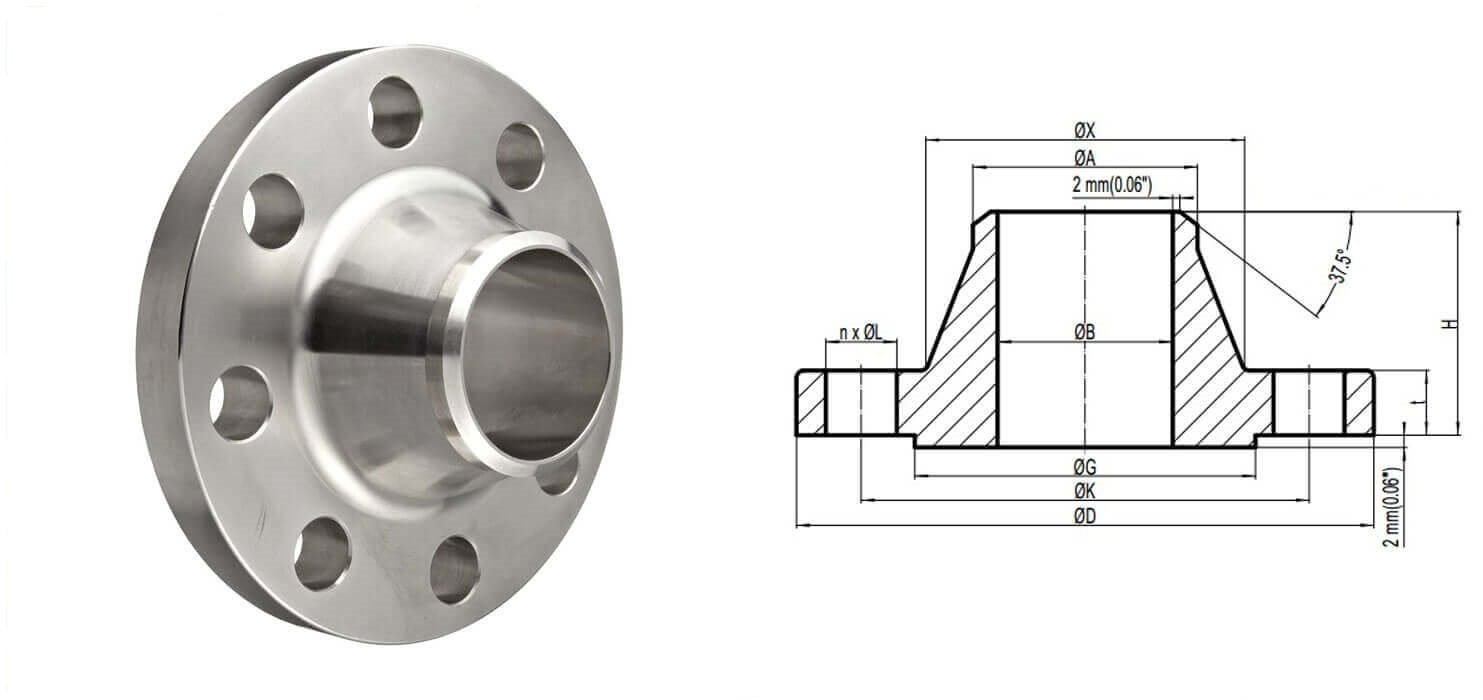

About Weld Neck Flanges

Weld neck flanges are essential in guaranteeing the safety and security of connections in the broad world of industrial piping systems. These flanges’ great pressure and temperature resistance have earned them widespread acclaim. Weld neck flanges are widely used in the oil and gas, chemical, petrochemical, and power generation industries due to their innovative design and construction.

The weld neck flange is distinguished by the pipe’s enlarged transition area, which can be seen by the flange’s long tapered hub (thus the name). Because of this design element, turbulence and pressure loss are kept to a minimum when fluids move through the system.

Weld neck flanges’ principal benefit is the uniform stress distribution throughout the flange and the pipeline. The lengthy hub reinforces, easing pressure on the flange’s base. This means the likelihood of fatigue failure is reduced, and the system’s overall safety is improved because weld neck flanges are so resistant to bending, thermal expansion, and contraction.

In addition, weld neck flanges’ adaptability to different pipe sizes and pressure classes makes them desirable. Carbon steel, stainless steel, alloy steel, and non-ferrous metals are just some of the materials from which they can be fabricated, ensuring they are compatible with a wide range of working conditions and fluids. Flanges can be protected from corrosion and erosion with the help of specific coatings and linings installed on the outside of the pipe.

Weld neck flanges are useful because they are simple to set up and repair. Welded joints don’t require regular tightening or adjustments because of their permanent nature. Their uniform dimensions and design parameters also make them interchangeable, which expedites the process of making repairs and minimizes disruptions to service.

Weld neck flanges, in conclusion, provide a secure and long-lasting link in industrial pipe systems. These flanges enhance the effectiveness and security of vital procedures because of their high strength, high-stress resistance, and high adaptability. In sectors where dangerous chemicals or high-pressure fluids must be transported or handled, weld neck flanges provide superior performance and peace of mind for engineers.

304 Stainless Steel Weldneck Flanges Stockist, Inconel 625 Weldneck Flanges Exporter, Duplex 31803 Weldneck Flanges Stockist, UNS N06625 Weldneck Flanges Exporter.

Specification of Weldneck Flanges

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Weld Neck Flanges |

| Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Weld Neck Flanges |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar Weld Neck Flanges |

| JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K Weld Neck Flanges |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized Weld Neck Flanges |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar Weld Neck Flanges |

| Most common types of Weld Neck Flanges | Forged / Threaded / Screwed / Plate |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

Dimensions Standard Of Weldneck Flanges

Class 150 Weld Neck Flange Dimensions

| Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Hub Diam. Chamfer of W.N | Lengtd Hub.Y | Bore | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | Approx. Weight | ||

| inch | dn | O | C | X | G | A | Y | B | BC | BH | BN | BD | KG | LB |

| 1/2″ | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 21.30 | 47.80 | 15.80 | 60.50 | 15.80 | 4 | 1/2″ | 0.7 | 1.5 |

| 3/4″ | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 26.70 | 52.30 | 20.80 | 69.90 | 15.80 | 4 | 1/2″ | 0.8 | 1.8 |

| 1″ | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 33.50 | 55.60 | 26.70 | 79.30 | 15.80 | 4 | 1/2″ | 1.1 | 2.4 |

| 1-1/4″ | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 42.20 | 57.20 | 35.10 | 88.90 | 15.80 | 4 | 1/2″ | 1.5 | 3.3 |

| 1-1/2″ | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 48.30 | 62.00 | 40.90 | 98.60 | 15.80 | 4 | 1/2″ | 1.8 | 4 |

| 2″ | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 60.50 | 63.50 | 52.60 | 120.70 | 19.10 | 4 | 5/8″ | 2.7 | 6 |

| 2-1/2″ | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 73.20 | 69.90 | 62.70 | 139.70 | 19.10 | 4 | 5/8″ | 4.4 | 9.8 |

| 3″ | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 88.90 | 69.90 | 78.00 | 152.40 | 19.10 | 4 | 5/8″ | 5.2 | 11.5 |

| 3-1/2″ | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 101.60 | 71.40 | 90.20 | 177.80 | 19.10 | 8 | 5/8″ | 6.4 | 14.2 |

| 4″ | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 114.30 | 76.20 | 102.40 | 190.50 | 19.10 | 8 | 5/8″ | 7.5 | 16.6 |

| 5″ | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 141.20 | 88.90 | 128.30 | 215.90 | 22.40 | 8 | 3/4″ | 9.2 | 20.2 |

| 6″ | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 168.40 | 88.90 | 154.20 | 241.30 | 22.40 | 8 | 3/4″ | 11 | 24.3 |

| 8″ | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 219.20 | 101.60 | 202.70 | 298.50 | 22.40 | 8 | 3/4″ | 18.4 | 40.6 |

| 10″ | 250 | 406.50 | 30.20 | 304.80 | 323.90 | 273.10 | 101.60 | 254.50 | 362.00 | 25.40 | 12 | 7/8″ | 25.5 | 56.2 |

| 12″ | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 323.90 | 114.30 | 304.80 | 431.80 | 25.40 | 12 | 7/8″ | 37 | 81.4 |

| 14″ | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 355.60 | 127.00 | 476.30 | 28.50 | 12 | 1″ | 51 | 113 | |

| 16″ | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 406.40 | 127.00 | 539.80 | 28.50 | 16 | 1″ | 61.5 | 136 | |

| 18″ | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 457.20 | 139.70 | 577.90 | 31.80 | 16 | 1 1/8″ | 71.5 | 158 | |

| 20″ | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 508.00 | 144.50 | 635.00 | 31.80 | 20 | 1 1/8″ | 85 | 187 | |

| 24″ | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 609.60 | 152.40 | 749.30 | 35.10 | 20 | 1 1/4″ | 119 | 262 | |

Class 300 Weld Neck Flange Dimensions

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Hub Diam. Chamfer of W.N | Lengtd Hub.Y | Bore | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | Approx. Weight | ||

| inch | dn | O | C | X | G | A | Y | B | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2″ | 15 | 95.5 | 14.2 | 38.1 | 35.1 | 21.3 | 52.3 | 15.7 | 66.5 | 15.7 | 4 | 1/2″ | 0.8 | 1.8 |

| 3/4″ | 20 | 117. 5 | 15.7 | 47.8 | 42.9 | 26.7 | 57.2 | 20.8 | 82.6 | 19.1 | 4 | 5/8″ | 1.4 | 3.1 |

| 1″ | 25 | 124. 0 | 17.5 | 53.8 | 50.8 | 33.5 | 62 | 26.7 | 88.9 | 19.1 | 4 | 5/8″ | 1.7 | 3.7 |

| 1-1/4″ | 32 | 133. 5 | 19.1 | 63.5 | 63.5 | 42.2 | 65 | 35.1 | 98.6 | 19.1 | 4 | 5/8″ | 2.2 | 4.8 |

| 1-1/2″ | 40 | 155. 5 | 20.6 | 69.9 | 73.2 | 48.3 | 68.3 | 40.9 | 114.3 | 22.4 | 4 | 5/8″ | 3.2 | 7 |

| 2″ | 50 | 165. 0 | 22.4 | 84.1 | 91.9 | 60.5 | 69.9 | 52.6 | 127 | 19.1 | 8 | 5/8″ | 3.6 | 7.9 |

| 2-1/2″ | 65 | 190. 5 | 25.4 | 100.1 | 104.6 | 73.2 | 76.2 | 62.7 | 149.4 | 22.4 | 8 | 3/4″ | 5.4 | 12 |

| 3″ | 80 | 209. 5 | 28.4 | 117.3 | 127 | 88.9 | 79.2 | 78 | 168.1 | 22.4 | 8 | 3/4″ | 7.3 | 16.1 |

| 3-1/2″ | 90 | 228. 5 | 30.2 | 133.4 | 139.7 | 101.6 | 81 | 90.2 | 184.2 | 22.4 | 8 | 3/4″ | 8.9 | 19.6 |

| 4″ | 100 | 254. 0 | 31.8 | 146.1 | 157.2 | 114.3 | 85.9 | 102.4 | 200.2 | 22.4 | 8 | 3/4″ | 11.8 | 26 |

| 5″ | 125 | 279. 5 | 35.1 | 177.8 | 185.7 | 141.2 | 98.6 | 128.3 | 235 | 22.4 | 8 | 3/4″ | 16 | 35.2 |

| 6″ | 150 | 317. 5 | 36.6 | 206.2 | 215.9 | 168.4 | 98.6 | 154.2 | 269.7 | 22.4 | 12 | 3/4″ | 20.2 | 44.6 |

| 8″ | 200 | 381. 0 | 41.1 | 260.4 | 269.7 | 219.2 | 111. 3 | 202.7 | 330.2 | 25.4 | 12 | 7/8″ | 31.2 | 68.8 |

| 10″ | 250 | 444. 5 | 47.8 | 320.5 | 323.9 | 273.1 | 117. 3 | 254.5 | 387.4 | 28.4 | 16 | 1″ | 44.3 | 97.5 |

| 12″ | 300 | 520. 5 | 50.8 | 374.7 | 381 | 323.9 | 130. 0 | 304.8 | 450.9 | 31.8 | 16 | 1 1/8″ | 63.5 | 140 |

| 14″ | 350 | 584. 0 | 53.8 | 425.5 | 412.8 | 355.6 | 142. 7 | 514..4 | 31.8 | 20 | 1 1/8″ | 86 | 190 | |

| 16″ | 400 | 647. 5 | 57.2 | 482.6 | 469.9 | 406.4 | 146. 1 | 571.5 | 35.1 | 20 | 1 1/4″ | 112 | 247 | |

| 18″ | 450 | 711. 0 | 60.5 | 533.4 | 533.4 | 457.2 | 158. 8 | 628.7 | 35.1 | 24 | 1 1/4″ | 141 | 310 | |

| 20″ | 500 | 774. 5 | 63.5 | 587.2 | 584.2 | 508 | 162. 1 | 685.8 | 35.1 | 24 | 1 1/4″ | 173 | 382 | |

| 24″ | 600 | 914. 5 | 69.9 | 701.5 | 692.2 | 609.6 | 168. 1 | 812.8 | 41.1 | 24 | 1 1/2″ | 248 | 546 | |

Class 600 Weld Neck Flange Dimensions

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Hub Diam. Chamfer of W.N | Lengtd Hub | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | Approx. Weight | ||

| inch | dn | O | C | X | G | A | Y | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2″ | 15 | 95.5 | 14.2 | 38.1 | 35.1 | 22.4 | 52.3 | 66.5 | 15.7 | 4 | 1/2″ | 0.9 | 2 |

| 3/4″ | 20 | 117. 5 | 15.7 | 47.8 | 42.9 | 25.4 | 57.2 | 82.6 | 19.1 | 4 | 5/8″ | 1.6 | 3.5 |

| 1″ | 25 | 124. 0 | 17.5 | 53.8 | 50.8 | 26.9 | 62 | 88.9 | 19.1 | 4 | 5/8″ | 1.9 | 4.2 |

| 1-1/4″ | 32 | 133. 5 | 20.6 | 63.5 | 63.5 | 28.4 | 66.5 | 98.6 | 19.1 | 4 | 5/8″ | 2.6 | 5.8 |

| 1-1/2″ | 40 | 155. 5 | 22.4 | 69.9 | 73.2 | 31.8 | 69.9 | 114.3 | 22.4 | 4 | 3/4″ | 3.6 | 8 |

| 2″ | 50 | 165. 0 | 25.4 | 84.1 | 91.9 | 36.6 | 73.2 | 127 | 19.1 | 8 | 5/8″ | 4.7 | 10.4 |

| 2-1/2″ | 65 | 190. 5 | 28.4 | 100.1 | 104.6 | 41.1 | 79.2 | 149.4 | 22.4 | 8 | 3/4″ | 4.8 | 15 |

| 3″ | 80 | 209. 5 | 31.8 | 117.3 | 127 | 46 | 82.6 | 168.1 | 22.4 | 8 | 3/4″ | 8.7 | 19.3 |

| 3-1/2″ | 90 | 228. 5 | 35.1 | 133.4 | 139.7 | 49.3 | 85.9 | 184.2 | 25.4 | 8 | 7/8″ | 11.6 | 25.5 |

| 4″ | 100 | 273. 0 | 38.1 | 152.4 | 157.2 | 53.8 | 101. 6 | 215.9 | 25.4 | 8 | 7/8″ | 18.4 | 40.5 |

| 5″ | 125 | 330. 0 | 44.5 | 189 | 185.7 | 60.5 | 114. 3 | 266.7 | 28.4 | 8 | 1″ | 31 | 68 |

| 6″ | 150 | 355. 5 | 47.8 | 222.3 | 215.9 | 66.5 | 117. 3 | 292.1 | 28.4 | 12 | 1″ | 37 | 81.4 |

| 8″ | 200 | 419. 0 | 55.6 | 273.1 | 269.7 | 76.2 | 133. 4 | 349.3 | 31.8 | 12 | 1 1/8″ | 54.5 | 120 |

| 10″ | 250 | 508. 0 | 63.5 | 342.9 | 323.9 | 85.9 | 152. 4 | 431.8 | 35.1 | 16 | 1 1/4″ | 98.5 | 195 |

| 12″ | 300 | 559. 0 | 66.5 | 400.1 | 381 | 91.9 | 155. 4 | 489 | 35.1 | 20 | 1 1/4″ | 105 | 231 |

| 14″ | 350 | 603. 5 | 69.9 | 431.8 | 412.8 | 93.7 | 165. 1 | 527.1 | 38.1 | 20 | 1 3/8″ | 150 | 330 |

| 16″ | 400 | 686. 0 | 76.2 | 495.3 | 469.9 | 106.4 | 177. 8 | 603.3 | 41.1 | 20 | 1 1/2″ | 177 | 390 |

| 18″ | 450 | 743. 0 | 82.6 | 546.1 | 533.4 | 117.3 | 184. 2 | 654.1 | 44.5 | 20 | 1 5/8″ | 228 | 503 |

| 20″ | 500 | 813. 0 | 88.9 | 609.6 | 584.2 | 127 | 190. 5 | 723.9 | 44.5 | 24 | 1 5/8″ | 285 | 628 |

| 24″ | 600 | 940. 0 | 101.6 | 717.6 | 692.2 | 139.7 | 203. 2 | 838.2 | 50.8 | 24 | 1 7/8″ | 372 | 820 |

Class 1500 Weld Neck Flanges Dimensions

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Hub Diam. Chamfer of W.N | Length Hub | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | Approx. Weight | ||

| inch | dn | O | C | X | A | Y | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2″ | 15 | 120.7 | 22.4 | 38.1 | 21.3 | 60.5 | 82.6 | 22.4 | 4 | 3/4″ | 2.1 | 4.6 |

| 3/4″ | 20 | 130 | 25.4 | 44.5 | 26.7 | 69.9 | 88.9 | 22.4 | 4 | 3/4″ | 2.7 | 5.9 |

| 1″ | 25 | 149.4 | 28.4 | 52.3 | 33.5 | 73.2 | 101.6 | 25.4 | 4 | 7/8″ | 3.9 | 8.6 |

| 1-1/4″ | 32 | 158.8 | 28.4 | 63.5 | 42.2 | 73.2 | 111.3 | 25.4 | 4 | 7/8″ | 4.5 | 9.9 |

| 1-1/2″ | 40 | 177.8 | 31.8 | 69.9 | 48.3 | 82.6 | 124 | 28.4 | 4 | 1″ | 6.2 | 13.7 |

| 2″ | 50 | 215.9 | 38.1 | 104.6 | 60.5 | 101.6 | 165.1 | 25.4 | 8 | 7/8″ | 11.3 | 24.9 |

| 2-1/2″ | 65 | 244.3 | 41.1 | 124 | 73.2 | 104.6 | 190.5 | 28.4 | 8 | 1″ | 16.3 | 36 |

| 3″ | 80 | 266.7 | 47.8 | 133.4 | 88.9 | 117.3 | 190.5 | 25.4 | 8 | 7/8″ | 21 | 46.3 |

| 4″ | 100 | 311.2 | 53.8 | 162.1 | 114.3 | 124 | 235 | 31.8 | 8 | 1 1/8″ | 31.8 | 70.1 |

| 5″ | 125 | 374.7 | 73.2 | 196.9 | 141.2 | 155.4 | 279.4 | 35.1 | 8 | 1 1/4″ | 59 | 129.8 |

| 6″ | 150 | 393.7 | 82.6 | 228.6 | 168.4 | 171.5 | 317.5 | 31.8 | 12 | 1 1/8″ | 72 | 158 |

| 8″ | 200 | 482.6 | 91.9 | 292.1 | 219.2 | 212.9 | 393.7 | 38.1 | 12 | 1 3/8″ | 124 | 273 |

| 10″ | 250 | 584.2 | 108 | 368.3 | 273.1 | 254 | 469.9 | 38.1 | 16 | 1 3/8″ | 207 | 456 |

| 12″ | 300 | 673.1 | 124 | 450.9 | 323.9 | 282.4 | 533.4 | 38.1 | 20 | 1 3/8″ | 306 | 674 |

| 14″ | 350 | 749.3 | 133.4 | 495.3 | 355.6 | 298.5 | 558.8 | 41.1 | 20 | 1 1/2″ | 416 | 917 |

| 16″ | 400 | 825.5 | 146.1 | 552.5 | 406.4 | 311.2 | 616 | 44.5 | 20 | 1 5/8″ | 567 | 1250 |

| 18″ | 450 | 914.4 | 162.1 | 596.9 | 457.2 | 327.2 | 685.8 | 50.8 | 20 | 1 7/8″ | 736 | 1623 |

| 20″ | 500 | 984.3 | 177.8 | 641.4 | 508 | 355.6 | 749.3 | 53.8 | 20 | 2″ | 929 | 2048 |

| 24″ | 600 | 1168.4 | 203.2 | 762 | 609.6 | 406.4 | 901.7 | 66.5 | 20 | 2 1/2″ | 1504 | 3316 |

Class 2500 Weld Neck Flanges Dimensions

| Nominal Pipe Size | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Hub Diam. Chamfer of W.N | Lengtd Hub.Y | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | Approx. Weight | ||

| inch | dn | O | C | X | A | Y | BC | BH | BN | BD | KG | LB |

| 1/2″ | 15 | 133.4 | 30.2 | 42.9 | 21.3 | 73.2 | 88.9 | 22.4 | 4 | 3/4″ | 3.2 | 7 |

| 3/4″ | 20 | 139.7 | 31.8 | 50.8 | 26.7 | 79.2 | 95.3 | 22.4 | 4 | 3/4″ | 3.6 | 8 |

| 1″ | 25 | 158.8 | 35.1 | 57.2 | 33.5 | 88.9 | 108 | 25.4 | 4 | 7/8″ | 5.4 | 12 |

| 1-1/4″ | 32 | 184.2 | 38.1 | 73.2 | 42.2 | 95.3 | 130 | 28.4 | 4 | 1″ | 7.8 | 17.2 |

| 1-1/2″ | 40 | 203.2 | 44.5 | 79.2 | 48.3 | 111.3 | 146.1 | 31.8 | 4 | 1 1/8″ | 11.5 | 25.4 |

| 2″ | 50 | 235 | 50.8 | 95.3 | 60.5 | 127 | 171.5 | 28.4 | 8 | 1″ | 19 | 42 |

| 2-1/2″ | 65 | 266.7 | 57.2 | 114.3 | 73.2 | 142.7 | 196.9 | 31.8 | 8 | 1 1/8″ | 24 | 52 |

| 3″ | 80 | 304.8 | 66.5 | 133.4 | 88.9 | 168.1 | 228.6 | 35.1 | 8 | 1 1/4″ | 42.6 | 94 |

| 4″ | 100 | 355.6 | 76.2 | 165.1 | 114.3 | 190.5 | 273.1 | 41.1 | 8 | 1 1/2″ | 64 | 141 |

| 5″ | 125 | 419.1 | 91.9 | 203.2 | 141.2 | 228.6 | 323.9 | 47.8 | 8 | 1 3/4″ | 111 | 244 |

| 6″ | 150 | 482.6 | 108 | 235 | 168.4 | 273.1 | 368.3 | 53.8 | 8 | 2″ | 171 | 378 |

| 8″ | 200 | 552.5 | 127 | 304.8 | 219.2 | 317.5 | 438.2 | 53.8 | 12 | 2″ | 261 | 576 |

| 10″ | 250 | 673.1 | 165.1 | 374.7 | 273.1 | 419.1 | 539.8 | 66.5 | 12 | 2 1/2″ | 485 | 1068 |

| 12″ | 300 | 762 | 184.2 | 441.5 | 323.9 | 463.6 | 619.3 | 73.2 | 12 | 2 3/4″ | 698 | 1539 |

Size Of Weldneck Flanges

| Nom Pipe Size | Outside Diam | Sched 10 | Sched 20 | Sched 30 | Std. Wall | Sched 40 | Sched 60 | Extra Strong | Sched 80 | Sched 100 | Sched 120 | Sched 140 | Sched 160 | Double Extra Strong |

| 1/2” | 0.840 | 0.674 | – | – | 0.622 | 0.622 | – | 0.546 | 0.546 | – | – | – | 0.464 | 0.252 |

| 3/4” | 1.050 | 0.884 | – | – | 0.824 | 0.824 | – | 0.742 | 0.742 | – | – | – | 0.612 | 0.434 |

| 1” | 1.315 | 1.097 | – | – | 1.049 | 1.049 | – | 0.957 | 0.957 | – | – | – | 0.815 | 0.599 |

| 1.1/4” | 1.660 | 1.442 | – | – | 1.380 | 1.380 | – | 1.278 | 1.278 | – | – | – | 1.160 | 0.896 |

| 1.1/2” | 1.900 | 1.682 | – | – | 1.610 | 1.610 | – | 1.500 | 1.500 | – | – | – | 1.338 | 1.100 |

| 2” | 2.375 | 2.157 | – | – | 2.067 | 2.067 | – | 1.939 | 1.939 | – | – | – | 1.687 | 1.503 |

| 2.1/2” | 2.875 | 2.635 | – | – | 2.469 | 2.469 | – | 2.323 | 2.323 | – | – | – | 2.125 | 1.771 |

| 3” | 3.500 | 3.260 | – | – | 3.068 | 3.068 | – | 2.900 | 2.900 | – | – | – | 2.624 | 2.300 |

| 3-1/2” | 4.000 | 3.760 | – | – | 3.548 | 3.548 | – | 3.364 | 3.364 | – | – | – | – | 2.728 |

| 4” | 4.500 | 4.260 | – | – | 4.026 | 4.026 | – | 3.826 | 3.826 | – | 3.624 | – | 3.438 | 3.152 |

| 5” | 5.563 | 5.295 | – | – | 5.047 | 5.047 | – | 4.813 | 4.813 | – | 4.563 | – | 4.313 | 4.063 |

| 6” | 6.625 | 6.357 | – | – | 6.065 | 6.065 | – | 5.761 | 5.761 | – | 5.501 | – | 5.187 | 4.897 |

| 8” | 8.625 | 8.329 | 8.125 | 8.071 | 7.981 | 7.981 | 7.813 | 7.625 | 7.625 | 7.437 | 7.187 | 7.001 | 6.813 | 6.875 |

| 10” | 10.750 | 10.420 | 10.250 | 10.136 | 10.020 | 10.020 | 9.750 | 9.750 | 9.562 | 9.312 | 9.062 | 8.750 | 8.500 | 8.750 |

| 12” | 12.750 | 12.390 | 12.250 | 12.090 | 12.000 | 11.938 | 11.626 | 11.750 | 11.374 | 11.062 | 10.750 | 10.500 | 10.126 | 10.750 |

| 14” | 14.000 | 13.500 | 13.376 | 13.250 | 13.250 | 13.124 | 12.812 | 13.000 | 12.500 | 12.124 | 11.814 | 11.500 | 11.188 | – |

| 16” | 16.000 | 15.500 | 15.376 | 15.250 | 15.250 | 15.000 | 14.688 | 15.000 | 14.312 | 13.938 | 13.564 | 13.124 | 12.812 | – |

| 18” | 18.000 | 17.500 | 17.376 | 17.124 | 17.250 | 16.876 | 16.500 | 17.000 | 16.124 | 15.688 | 15.250 | 14.876 | 14.438 | – |

| 20” | 20.000 | 19.500 | 19.250 | 19.000 | 19.250 | 18.812 | 18.376 | 19.000 | 17.938 | 17.438 | 17.000 | 16.500 | 16.062 | – |

| 24” | 24.000 | 23.500 | 23.250 | 22.876 | 23.250 | 22.624 | 22.062 | 23.000 | 21.562 | 20.938 | 20.376 | 19.876 | 19.312 | – |

| 30” | 30.000 | 29.376 | 29.000 | 28.750 | 29.250 | – | – | 29.000 | – | – | – | – | – | – |

| 36” | 36.000 | 35.376 | 35.000 | 34.750 | 35.250 | 34.500 | – | 35.000 | – | – | – | – | – | – |

| 42” | 42.000 | – | – | – | 41.250 | – | – | 41.000 | – | – | – | – | – | – |

Weight Chart Of Weldneck Flanges

| Nom Size | 150# | 300# | 600# | 900# | 1500# | 2500# | ||||||||||||

| WN | S/O | B/K | WN | S/O | B/K | WN | S/O | B/K | WN | S/O | B/K | WN | S/O | B/K | WN | S/O | B/K | |

| 1/2” | 0.7 | 0.4 | 0.5 | 0.8 | 0.7 | 0.8 | 0.9 | 0.8 | 0.8 | 2.1 | 1.8 | 1.9 | 2.1 | 1.8 | 1.9 | 3.2 | 3 | 3 |

| 3/4” | 0.8 | 0.7 | 0.8 | 1.4 | 1.2 | 1.2 | 1.6 | 1.4 | 1.4 | 2.7 | 2.4 | 2.7 | 2.7 | 2.4 | 2.7 | 3.6 | 4 | 4.5 |

| 1” | 1.1 | 0.8 | 0.9 | 1.7 | 1.4 | 1.5 | 1.9 | 1.7 | 1.7 | 3.9 | 3.6 | 3.7 | 3.9 | 3.6 | 3.7 | 5.4 | 5 | 5 |

| 1.1/4” | 1.5 | 1.2 | 1.3 | 2.2 | 1.8 | 2 | 2.6 | 2.1 | 2.4 | 4.5 | 4.1 | 4.3 | 4.5 | 4.1 | 4.3 | 7.8 | 8 | 8 |

| 1.1/2” | 1.8 | 1.4 | 1.6 | 3.2 | 2.7 | 2.9 | 3.6 | 3.1 | 3.4 | 6.2 | 5.4 | 5.9 | 6.2 | 5.4 | 5.9 | 11.5 | 11 | 11 |

| 2” | 2.7 | 2.2 | 2.6 | 3.6 | 3.2 | 3.5 | 4.7 | 3.9 | 4.4 | 11.3 | 10.5 | 11.3 | 11.3 | 10.5 | 11.3 | 19 | 17 | 17 |

| 2.1/2” | 4.4 | 3.5 | 4.1 | 5.4 | 4.5 | 5.3 | 4.8 | 5.4 | 6.8 | 16.3 | 15.8 | 16 | 16.3 | 15.8 | 16 | 24 | 25 | 25 |

| 3” | 5.2 | 3.8 | 5.1 | 7.3 | 5.9 | 7.2 | 8.7 | 7.3 | 8.9 | 15 | 12.3 | 16.8 | 21 | 21.5 | 19.5 | 42.6 | 38 | 39 |

| 3-1/2” | 6.4 | 5 | 6.5 | 8.9 | 7.5 | 9.2 | 11.6 | 9 | 12.7 | – | – | – | – | – | – | – | – | – |

| 4” | 7.5 | 5.6 | 7.5 | 11.8 | 10 | 12.2 | 18.4 | 16.5 | 18.6 | 24 | 23.2 | 24.5 | 31.8 | 31 | 33 | 64 | 58 | 60 |

| 5” | 9.2 | 6.5 | 9.2 | 16 | 12.5 | 16 | 31 | 28.5 | 30.8 | 38.5 | 37.5 | 39.5 | 59 | 58.8 | 60 | 111 | 95 | 101 |

| 6” | 11.0 | 8.1 | 11.8 | 20.2 | 16.5 | 22 | 37 | 36.2 | 38 | 50 | 48.3 | 51.5 | 72 | 74 | 75 | 171 | 146 | 156 |

| 8” | 18.4 | 13 | 20.4 | 31.2 | 25.5 | 36 | 54.5 | 51.5 | 62.2 | 85 | 75 | 89 | 124 | 112 | 125 | 261 | 220 | 242 |

| 10” | 25.5 | 18.4 | 31 | 44.3 | 35 | 55 | 98.5 | 76.2 | 102 | 123 | 110 | 131 | 207 | 184 | 215 | 485 | 420 | 465 |

| 12” | 37 | 28.5 | 47 | 63.5 | 52 | 82.5 | 105 | 89.5 | 132 | 168 | 146 | 187 | 306 | 264 | 316 | 698 | 590 | 665 |

| 14” | 51 | 37.5 | 60 | 86 | 73 | 108 | 150 | 102 | 158 | 198 | 172 | 224 | 416 | – | – | – | – | – |

| 16” | 61.5 | 44.5 | 61 | 112 | 88 | 139 | 177 | 150 | 225 | 225 | 192 | 259 | 567 | – | – | – | – | – |

| 18” | 71.5 | 54 | 93 | 141 | 115 | 178 | 228 | 180 | 285 | 318 | 272 | 383 | 736 | – | – | – | – | – |

| 20” | 85 | 72 | 127 | 173 | 139 | 228 | 285 | 231 | 365 | 376 | 330 | 482 | 929 | – | – | – | – | – |

| 24” | 119 | 95 | 190 | 248 | 212 | 350 | 372 | 330 | 532 | 680 | 632 | 905 | 1504 | – | – | – | – | – |

Pressure Rating Of Weldneck Flanges

| ANSI/ASME B16.34 | ANSI PRESSURE RATING | ||||||

| Temperature (in F°) | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| < 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| Hydrostatic Test Pressure (in Psig) | 450 | 1125 | 1500 | 2225 | 3350 | 5575 | 9275 |

| ANSI/ASME B16.34 | ANSI PRESSURE RATING | ||||||

| Temperature in C° | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -29 / 38 | 19.6 | 51.1 | 68.1 | 102.1 | 153.2 | 255.3 | 425.5 |

| 50 | 19.2 | 50.1 | 66.8 | 100.2 | 150.4 | 250.6 | 417.7 |

| 100 | 17.7 | 46.6 | 62.1 | 93.2 | 139.8 | 233 | 388.3 |

| 150 | 15.8 | 45.1 | 60.1 | 90.2 | 135.2 | 225.4 | 375.6 |

| 200 | 13.8 | 43.8 | 58.4 | 87.6 | 131.4 | 219 | 365 |

| 250 | 12.1 | 41.9 | 55.9 | 83.9 | 125.8 | 209.7 | 349.5 |

| 300 | 10.2 | 39.8 | 53.1 | 79.6 | 119.5 | 199.1 | 331.8 |

| 325 | 9.3 | 38.7 | 51.6 | 77.4 | 116.1 | 193.6 | 322.6 |

| 350 | 8.4 | 37.6 | 50.1 | 75.1 | 112.7 | 187.8 | 313 |

| 375 | 7.4 | 36.4 | 48.5 | 72.7 | 109.1 | 181.8 | 303.1 |

| 400 | 6.5 | 34.7 | 46.3 | 69.4 | 104.2 | 173.6 | 289.3 |

| 425 | 5.5 | 28.8 | 38.4 | 57.5 | 86.3 | 143.8 | 239.7 |

| 450 | 4.6 | 23 | 30.7 | 46 | 69 | 115 | 191.7 |

| 475 | 3.7 | 17.4 | 23.2 | 34.9 | 52.3 | 87.2 | 145.3 |

| 500 | 2.8 | 11.8 | 15.7 | 23.5 | 35.3 | 58.8 | 97.9 |

Price Of Weldneck Flanges

| Stainless Steel Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| High Nickel Alloys Flanges | USD $8.10 - $20.20 / Piece (FOB Price) on request |

| Duplex & Super Duplex Flange | USD $10.20 - $35.50 / Piece (FOB Price) on request |

| Cupro Nickel Flanges | USD $5.19 - $10.48 / Piece (FOB Price) on request |

| Carbon Steel Flanges | USD $2.08 - $7.10 / Piece (FOB Price) on request |

Application Of Weldneck Flanges

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Weldneck Flanges

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

Packing Of Weldneck Flanges

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

WRN 2.4856 Weldneck Flanges Price List, ASME SA182 SS 316 Weldneck Flanges Price Per Kg, 304 Stainless Steel Weldneck Flanges Weight Calculator, Duplex 31803 Weldneck Flanges Price Per Kg, UNS N06625 Weldneck Flanges Weight Chart, Inconel 625 Weldneck Flanges At Factory Price, UNS N08904 Weldneck Flanges Weight Calculator, UNS S30400 Weldneck Flanges Price List In India, 2507 Super Duplex Weldneck Flanges At Factory Price, ASME SA182 Duplex 2205 Weldneck Flanges At Factory Price, DIN 1.4301 Weldneck Flanges Catalogue.

Hastelloy C276 Weldneck Flanges Stockist in Pimpri-Chinchwad, ASME SA182 SS 316 Weldneck Flanges Supplier in Coimbatore, ASME SA182 Duplex 2205 Weldneck Flanges Stockist in Chennai, ASTM A182 SS 304 Weldneck Flanges Manufacturer in Bengaluru, UNS N06625 Weldneck Flanges Stockist in Bangalore, Inconel 625 Weldneck Flanges Supplier in Hyderabad, UNS S30400 Weldneck Flanges Manufacturer in Mumbai, DIN 1.4301 Weldneck Flanges Stockist in Ahmedabad, UNS N08904 Weldneck Flanges Supplier in Hyderabad, 2507 Super Duplex Weldneck Flanges Supplier in Pune.

304 Stainless Steel Weldneck Flanges Stockist in AustraliaUNS N08904 Weldneck Flanges Exporter in Kuwait, Inconel 625 Weldneck Flanges Exporter in Indonesia,WRN 2.4856 Weldneck Flanges Manufacturer in Vietnam, UNS N06625 Weldneck Flanges Exporter in South Africa, UNS S30400 Weldneck Flanges Manufacturer in Singapore, ASME SA182 Duplex 2205 Weldneck Flanges Stockist in UAE, DIN 1.4301 Weldneck Flanges Stockist in Malaysia,2507 Super Duplex Weldneck Flanges Supplier in Qatar,

Types of Flanges

- Forge Flange

- Blind Flange

- Slip On Flange

- Weldneck Flange

- Lap Joint Flange

- Threaded Flange

- Socketweld Flange

- Long Weld Neck Flange

- Weldo / Nipo Flange

- Orifice Flange

- Reducing Flange

- Flat Flange

- Loose Flange

- RTJ Flanges

- SORF Flanges

- Square Flanges

- SWRF Flanges

- Expander Flanges

- WNRF Flanges

- Ring Type Joint Flanges

- Groove & Tongue Flanges

- Spectacle Blind Flanges

- Weld Neck Flanges A / B Flanges

- Spades Ring Spacers Flanges

- Screwed Flanges

- Forging Facing Flanges

- Flanges Bolts