Nickel 200/ 201 Buttweld Fittings

UNS N02201 Short Radius, Nickel Alloys 201 90 Degree Elbow, UNS N02201 Pipe End Cap, Nickel 200 3D Elbow, UNS N02200 LR Return Bend, 201 Nickel Long Radius, DIN 2.4066 Exhaust Pipe Reducer.

About Nickel 200/ 201 Buttweld Fittings

Nissan Steel is a promising manufacturer and stockist of Nickel 200 Buttweld Fittings, and it is one of the companies that makes these fittings. Several different industries that make things prefer this product to all others. They are an excellent option for more business-oriented jobs. You can get them in different sizes, thicknesses, shapes, dimensions, polishes, finishes, etc. There needs to be a priority placed on the wants of the customers.

They are very corrosion-resistant because they have a lot of nickel in them. In addition, grades 200 and 201 comprise carbon, manganese, silicon, sulfur, copper, and ferrous iron. This chemical structure has an impressive range of electrical and thermal conductivity. Even though it’s hot, they can work well in the environment they are in. The melting point is 1446 degrees Celsius (or 2635 degrees Fahrenheit). It also has the widest range of tensile and yield strengths.

The American Society for Testing and Materials (ASTM) B366 and the American Society of Mechanical Engineers (ASME) SB366 are the standards that control the specifications, chemical properties, and mechanical qualities of grades 200 and 201.

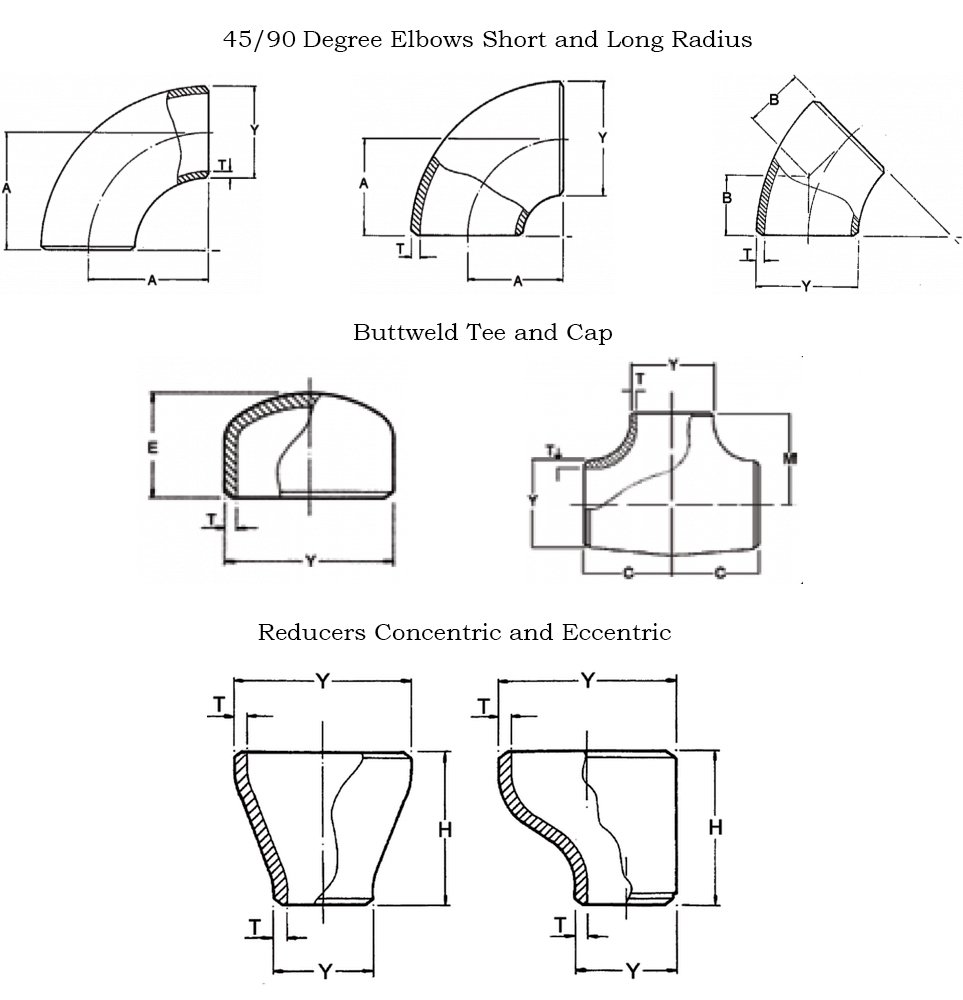

Buttweld fittings are categorised based on how they look and what they are used for. These connect two pipes and spread the fluid going through them out evenly. Similarly, there are a few kinds of Nickel 200/201 Buttweld Fittings, such as a 45-degree elbow, crosses, reducers, caps, stub ends, unions, couplings, threaded pipe fittings, and so on.

Nickel 200/201 buttweld fittings can be packaged according to customer specifications or the general approach. Before they are packed, they must pass several important tests, such as the PMI test, chemical and mechanical analysis, 100% raw material authenticity testing, third-party inspection, radiography test, and others.

DIN 2.4066 Exhaust Pipe Reducer Supplier, Nickel Alloys 201 1.5D Elbow Exporter, 200 Nickel Elbow Exporter, Nickel 200 Pipe Nipple Stockist, 201 Nickel Eccentric Reducer Exporter.

Specification of Nickel 200/ 201 Buttweld Fittings

| Specification | ASTM B366 / ASME SB366 |

| Standard | EN, ISO, DIN, JIS, NPT |

| Dimension Standard | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Size | 1/8” NB TO 48” NB. (Seamless & 100% X-Ray Welded, Fabricated) |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom ASTM A403 Grade WP317L Pipe Fitting |

| Type | Seamless / Welded / Fabricated |

| Pressure-Temperature Class | 150LB, 300LB, 600LB, 1500LB, 2500LB. |

| Schedule | Schedule 5 TO Schedule XXS. |

| Type Of Dimension | BS1640, EN 10253 - 4, DIN 2605, JIS B2312, ANSI B16.9, MSS SP-75, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2313 |

Ready stock of available for Nickel 200/ 201 Buttweld Fittings

Equivalent Grades of Nickel 200/ 201 Buttweld Fittings

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Nickel 200 | 2.4066 | N02200 | NW 2200 | NA 11 | НП-2 | N-100M | Ni 99.2 |

| Nickel 201 | 2.4068 | N02201 | NW 2201 | NA 12 | НП-2 | – | LC-Ni 99 |

Chemical Composition of Nickel 200/ 201 Buttweld Fittings

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| Nickel 201 | 0.02 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Mechanical Properties of Nickel 200/ 201 Buttweld Fittings

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Nickel 200 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

| Nickel 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

Other Types of Nickel 200/ 201 Buttweld Fittings

Dimensions Standard Of Nickel 200/ 201 Buttweld Fittings

| Nominal Pipe Size | Outside Diameter | Caps | Straight Tees | Straight Crosses | Stub Ends | |||

| inch | mm | inch | Length (inch) | Center to End (inch) | Center to End (inch) | Lap Diameter (inch) | Long Length (inch) | Short Length (inch) |

| 1/2 | 21.3 | 0.840 | 1 | 1 | – | 1 3/8 | 3 | 2 |

| 3/4 | 26.7 | 1.050 | 1 | 1 1/8 | – | 1 11/16 | 3 | 2 |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 1/2 | 1 1/2 | 2 | 4 | 2 |

| 1 1/4 | 42.2 | 1.660 | 1 1/2 | 1 7/8 | 1 7/8 | 2 1/2 | 4 | 2 |

| 1 1/2 | 48.3 | 1.900 | 1 1/2 | 2 1/4 | 2 1/4 | 2 7/8 | 4 | 2 |

| 2 | 60.3 | 2.375 | 1 1/2 | 2 1/2 | 2 1/2 | 3 5/8 | 6 | 2 1/2 |

| 2 1/2 | 73.0 | 2.875 | 1 1/2 | 3 | 3 | 4 1/8 | 6 | 2 1/2 |

| 3 | 88.9 | 3.500 | 2 | 3 3/8 | 3 3/8 | 5 | 6 | 2 1/2 |

| 3 1/2 | 101.6 | 4.000 | 2 1/2 | 3 3/4 | 3 3/4 | 5 1/2 | 6 | 3 |

| 4 | 114.3 | 4.500 | 2 1/2 | 4 1/8 | 4 1/8 | 6 3/16 | 6 | 3 |

| 5 | 141.3 | 5.563 | 3 | 4 7/8 | 4 7/8 | 7 5/16 | 8 | 3 |

| 6 | 168.3 | 6.625 | 3 1/2 | 5 5/8 | 5 5/8 | 8 1/2 | 8 | 3 1/2 |

| 8 | 219.1 | 8.625 | 4 | 7 | 7 | 10 5/8 | 8 | 4 |

| 10 | 273.1 | 10.750 | 5 | 8 1/2 | 8 1/2 | 12 3/4 | 10 | 5 |

| 12 | 323.9 | 12.750 | 6 | 10 | 10 | 15 | 10 | 6 |

Size Of Nickel 200/ 201 Buttweld Fittings

| Product | Size* | Wall Thickness** | Seamless | Welded |

| Elbow | 1/2"-24" | SCH10S~XXS | √ | √ |

| 8"-104" | SCH5S~80S/XS | √ | ||

| Tee | 1/2"-24" | SCH10S~XXS | √ | √ |

| 8"-104" | SCH5S~80S/XS | √ | ||

| Reducer | 1/2"-24" | SCH10S~XXS | √ | √ |

| 8"-104" | SCH5S~80S/XS | √ | ||

| Cap | 1/2"-80" | SCH10S~SCH160 | √ | |

| Lap Joint Stub End | 1/2"-24" | SCH5S~80S/XS | √ | √ |

| 8"-80" | SCH5S~80S/XS | √ |

Weight Chart Of Nickel 200/ 201 Buttweld Fittings

| DN | Schedule 10S | Schedule 40S | Schedule 80S | ||||||

| 900 Elbow | 450 Elbow | Equal tee | 900 Elbow | 450 Elbow | Equal tee | 900 Elbow | 450 Elbow | Equal tee | |

| 8 | 0.02 | 0.01 | 0.03 | 0.03 | 0.02 | 0.06 | 0.04 | 0.03 | 0.07 |

| 10 | 0.03 | 0.02 | 0.05 | 0.03 | 0.02 | 0.03 | 0.06 | 0.04 | 0.09 |

| 15 | 0.06 | 0.03 | 0.09 | 0.08 | 0.04 | 0.10 | 0.10 | 0.05 | 0.14 |

| 20 | 0.07 | 0.03 | 0.13 | 0.08 | 0.04 | 0.17 | 0.11 | 0.05 | 0.20 |

| 25 | 0.14 | 0.08 | 0.28 | 0.15 | 0.11 | 0.29 | 0.22 | 0.14 | 0.38 |

| 32 | 0.23 | 0.11 | 0.49 | 0.26 | 0.17 | 0.59 | 0.40 | 0.23 | 0.68 |

| 40 | 0.30 | 0.17 | 0.68 | 0.40 | 0.23 | 0.86 | 0.51 | 0.29 | 1.02 |

| 50 | 0.50 | 0.25 | 0.85 | 0.70 | 0.4 | 1.28 | 0.91 | 0.59 | 1.59 |

| 65 | 0.85 | 0.48 | 1.41 | 1.40 | 0.77 | 2.19 | 1.81 | 0.99 | 3.13 |

| 80 | 1.25 | 0.63 | 1.77 | 2.20 | 1.08 | 3.31 | 2.97 | 1.50 | 4.45 |

| 90 | 1.70 | 0.75 | 2.67 | 2.83 | 1.42 | 4.08 | 4.00 | 2.00 | 5.44 |

| 100 | 2.10 | 1.08 | 3.46 | 4.47 | 2.09 | 5.27 | 6.18 | 2.81 | 7.71 |

| 150 | 5.45 | 2.72 | 8.07 | 10.89 | 5.44 | 10.99 | 16.32 | 8.16 | 13.61 |

| 200 | 10.20 | 5.33 | 15.65 | 21.54 | 10.77 | 20.91 | 33.11 | 16.56 | 28.12 |

| 250 | 18.15 | 9.75 | 26.46 | 38.56 | 19.27 | 35.38 | 51.71 | 25.86 | 49.90 |

| 300 | 25.80 | 13.62 | 39.46 | 59.42 | 29.71 | 62.14 | 79.38 | 39.69 | 83.91 |

| DN | Schedule 10S | Schedule 40S | Schedule 80S | ||||||

| Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | |

| 40x.25 | 0.19 | 0.19 | 0.60 | 0.26 | 0.26 | 0.76 | 0.34 | 0.34 | 0.90 |

| 50x25 | 0.28 | 0.28 | 0.73 | 0.40 | 0.40 | 1.10 | 0.54 | 0.54 | 1.37 |

| 50x40 | 0.31 | 0.31 | 0.76 | 0.45 | 0.45 | 1.15 | 0.59 | 0.59 | 1.43 |

| 80x.50 | 0.55 | 0.55 | 1.56 | 1.00 | 1.00 | 2.91 | 1.79 | 1.79 | 3.91 |

| 100x50 | 0.78 | 0.78 | 2.94 | 1.50 | 1.50 | 4.48 | 1.95 | 1.95 | 6.55 |

| 100x80 | 0.87 | 0.87 | 3.04 | 1.74 | 1.74 | 4.64 | 2.33 | 2.33 | 6.79 |

| 150x80 | 1.82 | 1.82 | 6.86 | 3.95 | 3.95 | 9.68 | 5.51 | 5.51 | 11.57 |

| 150x100 | 1.96 | 1.96 | 7.10 | 4.07 | 4.07 | 11.94 | 5.96 | 5.96 | 11.97 |

| 200x100 | 3.01 | 3.01 | 13.46 | 6.55 | 6.55 | 17.98 | 9.23 | 9.23 | 24.18 |

| 200x150 | 3.19 | 3.19 | 14.08 | 6.74 | 6.74 | 18.82 | 10.12 | 10.12 | 25.31 |

Pressure Rating Of Nickel 200/ 201 Buttweld Fittings

| (oF) | (oC) | 150 |

| -20 to 150 | -29 to 66 | 300 |

| 200 | 93 | 265 |

| 250 | 121 | 225 |

| 300 | 149 | 185 |

| 350 | 177 | 150 |

| 400 | 204 | - |

| 450 | 232 | - |

| 500 | 260 | - |

| 550 | 288 | - |

industrial use fitting for Nickel 200/ 201 Buttweld Fittings

Price Of Nickel 200/ 201 Buttweld Fittings

| High Nickel Alloys Elbow | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Equal Tee | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Reducing Tee | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Cross | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Cap | USD $8.11 - $20.21 / Piece (FOB Price) on request |

Application Of Nickel 200/ 201 Buttweld Fittings

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Nickel 200/ 201 Buttweld Fittings

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

Packing Of Nickel 200/ 201 Buttweld Fittings

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates