Carbon Steel A106 Pipe & Tube

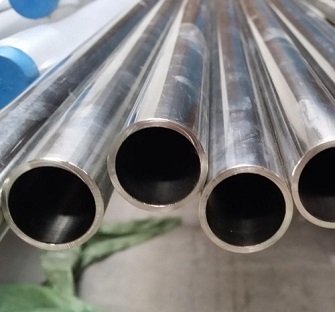

Carbon Steel A106 IBR Pipe, Carbon Steel A106 Rectangular Pipe, ANSI B16.5 Spiral Welded Pipe, A106 Carbon Steel Cold Drawn Seamless Tube, A106 Carbon Steel Triangle Tube.

About Carbon Steel A106 Pipe & Tube

ASTM A106 seamless pipe, or ASME SA106 pipes, is a seamless pipe used to move gas and liquids from one location to another. ASTM A106 pipes are ideally suited for high-temperature and high-pressure applications. These pipes are made following ANSI B36.10 / ASME B36.10 dimensional specifications. ASTM A106 Grade B is the most often used pipe, and it is the customers’ first choice because of its low cost and global availability. The pipes have a minimum yield strength of 240 MPa for Grade B pipes and 275 MPa for Grade C pipes, and a minimum increase of 16.5%/30% for Grade B pipes and 415 MPa for Grade C pipes. Pipes are manufactured using either the cold draw finish or the hot finish. Cold-drawn finish pipes need a normalizing heat treatment at 900 degrees. C. These pipes are primarily used in oil and gas refineries, petrochemical facilities, boilers, chemical plants, and shipbuilding sectors.

Nissan Steel is India’s largest provider of carbon steel seamless pipes. We provide high-quality tubes to consumers all around the globe. Tubes are supplied in NPS/NB dimensions following ASME B36.10 in various thicknesses to meet our customers’ needs. Before being delivered to the customer, our in-house quality control staff thoroughly examines all pipes provided by us. All pipes have complete traceability and a mill test certificate under EN 10204 3.1. We provide affordable rates and excellent service to our consumers. Pipe bought in accordance with these standards must be appropriate for bending, flanging, and similar forming operations, as well as welding.

Carbon A106 Welded Pipe Stockist, A106 Carbon Steel Cold Drawn Seamless Tube Exporter, Carbon Steel A106 Slot Round Pipe Exporter.

Specification of Carbon Steel A106 Pipe & Tube

| Specifications | ASTM A106 |

| Dimensional specification | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| Size | 1 / 8" NB - 24" NB |

| Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock |

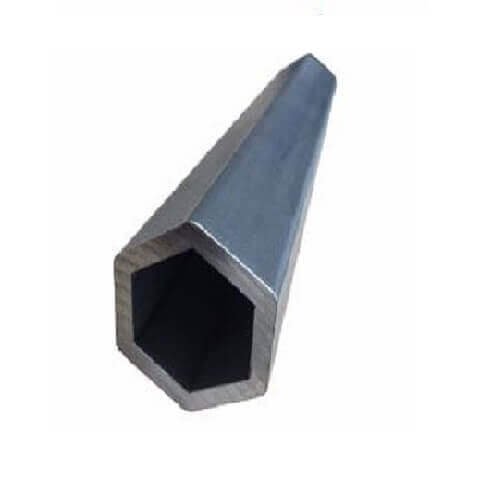

| Manufacturing Shapes | Hydraulic, Round, Square, Hex, Honed |

| Manufacturing Techniques | Normalized & as Rolled |

| Schedule Thickness Range | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| End Types | Plain End, Beveled End, Treaded One End, TBE (Treaded Both Ends) |

| Surface Finish | No.1, No.4, No.8 Mirror Finish, 2B |

| Value Added Services | Cutting, Beveling, Polishing, Threading, Destructive, Non Destructive, Ultrasonic Testing |

| Inspection and Test Reports | EN 10204 3.1, Mill Test Certificates, Chemical Reports, PMI Test Reports, Mechanical Reports, Third Party Inspection, NABL Approved Lab, Visual Inspection, Destructive Test and Non Destructive Test Reports |

| Outside Finish | 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Seamless Pipes, Finish as per customer Requirements |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Heat Treatment | Normalized, Normalized & Tempered |

| Packing of Seamless Pipes | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be on request |

Ready stock of available for Carbon Steel A106 Pipe & Tube

Chemical Composition of Carbon Steel A106 Pipe & Tube

| Grade A | Grade B | Grade C | |

| Carbon max. % | 0.25 | 0.30 | 0.35 |

| Manganese % | 0.27 to 0.93 | 0.29 to 1.06 | 0.29 to 1.06 |

| Phosporous, max. % | 0.025 | 0.025 | 0.025 |

| Sulfur, max. % | 0.025 | 0.025 | 0.025 |

| Silicon, min. % | 0.10 | 0.10 | 0.10 |

Mechanical Properties of Carbon Steel A106 Pipe & Tube

| Seamless | Grade A | Grade B | Grade C |

| Tensile Strength, min., psi | 48,000 | 60,000 | 70,000 |

| Yield Strength, min., psi | 30,000 | 35,000 | 40,000 |

Other Types of Carbon Steel A106 Pipe & Tube

Dimensions Standard Of Carbon Steel A106 Pipe & Tube

| Nominal Pipe Size | Outside Diameter (mm) | Nominal Wall Thickness Schedule | |||||||||||||||||

| NPS | DN | OD | SCH5s | SCHl0s | SCH 10 | SCH 20 | SCH 30 | SCH40s | SCH STD | SCH 40 | SCH 60 | SCH80s | SCH XS | SCH 80 | SCH 100 | SCH 120 | SCH 140 | SCH 160 | SCH XXS |

| 1/8 | 6 | 10.3 | 1.24 | 1.73 | 1.73 | 1.73 | 2.41 | 2.41 | 2.41 | ||||||||||

| 1/4 | 8 | 13.7 | 1.65 | 2.24 | 2.24 | 2.24 | 3.02 | 3.02 | 3.02 | ||||||||||

| 3/8 | 10 | 17.1 | 1.65 | 2.31 | 2,31 | 2.31 | 3.20 | 3.20 | 3.20 | ||||||||||

| 1/2 | 15 | 21.3 | 1.65 | 2.11 | 2.77 | 2.77 | 2.77 | 3.73 | 3.73 | 3.73 | 4.78 | 7.47 | |||||||

| 3/4 | 20 | 26.7 | 1.65 | 2.11 | 2.87 | 2.87 | 2.87 | 3.91 | 3.91 | 3.91 | 5.56 | 7.82 | |||||||

| 1 | 25 | 33.4 | 1.65 | 2.77 | 3.38 | 3.38 | 3.38 | 4.55 | 4.55 | 4.55 | 6.35 | 9.09 | |||||||

| 1 1/4 | 32 | 42.2 | 1.65 | 2.77 | 3.56 | 3.56 | 3,56 | 4.85 | 4.85 | 4.85 | 6.35 | 9.70 | |||||||

| 1 1/2 | 40 | 48.3 | 1.65 | 2.77 | 3.68 | 3.68 | 3.68 | 5.08 | 5.08 | 5.08 | 7.14 | 10.15 | |||||||

| 2 | 50 | 60.3 | 1.65 | 2.77 | 3.91 | 3.91 | 3.91 | 5.54 | 5.54 | 5.54 | 8.74 | 11.07 | |||||||

| 2 1/2 | 65 | 73 | 2.11 | 3.05 | 5.16 | 5.16 | 5.16 | 7.01 | 7.01 | 7.01 | 9.53 | 14.02 | |||||||

| 3 | 80 | 88.9 | 2.11 | 3.05 | 5.49 | 5.49 | 5.49 | 7.62 | 7.62 | 7.62 | 11.13 | 15.24 | |||||||

| 3 1/2 | 90 | 101.6 | 2.11 | 3.05 | 5.74 | 5.74 | 5.74 | 8.08 | 8.08 | 8.08 | |||||||||

| 4 | 100 | 114.3 | 2.11 | 3.05 | 6.02 | 6.02 | 6.02 | 8.56 | 8.56 | 8.56 | 11.13 | 13.49 | 17.12 | ||||||

| 5 | 125 | 141.3 | 2.77 | 3.40 | 6.55 | 6.55 | 6.55 | 9.53 | 9,53 | 9.53 | 12.70 | 15.88 | 19.05 | ||||||

| 6 | 150 | 168.3 | 2.77 | 3.40 | 7.11 | 7.11 | 7.11 | 10.97 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | ||||||

| 8 | 200 | 219.1 | 2.77 | 3.76 | 6.35 | 7.04 | 8.18 | 8.18 | 8.18 | 10.31 | 12.70 | 12.70 | 12.70 | 15.09 | 18.26 | 20.62 | 23.01 | 22.23 | |

| 10 | 250 | 273.1 | 3.40 | 4.19 | 6.35 | 7.80 | 9.27 | 9.27 | 9.27 | 12.70 | 12.70 | 12.70 | 15.09 | 18.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 12 | 300 | 323.9 | 3.96 | 4.57 | 6.35 | 8.38 | 9.53 | 9.53 | 10.31 | 14.27 | 12.70 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 14 | 350 | 355.6 | 3.96 | 4.78 | 6.35 | 7.92 | 9.53 | 9.53 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |||

| 16 | 400 | 406.4 | 4.19 | 4.78 | 6.35 | 7.92 | 9.53 | 9.53 | 12.70 | i6.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |||

| 18 | 450 | 457.2 | 4.19 | 4.78 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39,67 | 45.24 | |||

| 20 | 500 | 508 | 4.78 | 5.54 | 6.35 | 9.53 | 12.70 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |||

| 22 | 559 | 4.78 | 5.54 | 6.35 | 9.53 | 12.70 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | |||||

| 24 | 600 | 610 | 5.54 | 6.35 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |||

| 26 | 660 | 7.92 | 12.70 | 9.53 | 12.70 | ||||||||||||||

| 28 | 700 | 711 | 7.92 | 12.70 | 15.88 | 9.53 | 12.70 | ||||||||||||

| 30 | 762 | 6.35 | 7.92 | 7.92 | 12.70 | 15.88 | 9.53 | 12.70 | |||||||||||

| 32 | 800 | 813 | 7.92 | 12.70 | 15.88 | 9.53 | 17.48 | 12.70 | |||||||||||

| 34 | 884 | 7.92 | 12.70 | 15.88 | 9.53 | 17.48 | 12.70 | ||||||||||||

| 36 | 900 | 914 | 7.92 | 12.70 | 15.88 | 9.53 | 19.05 | 12.70 | |||||||||||

| 38 | 965 | 9.53 | 12.70 | ||||||||||||||||

| 40 | 1000 | 1016 | 9.53 | 12.70 | |||||||||||||||

| 42 | 1067 | 12.70 | 15.88 | 9.53 | 19.05 | 12.70 | |||||||||||||

| 44 | 1100 | 1118 | 9.53 | 12.70 | |||||||||||||||

| 46 | 1168 | 9.53 | 12.70 | ||||||||||||||||

| 48 | 1200 | 1219 | 9.53 | 12.70 | |||||||||||||||

| 52 | 1321 | ||||||||||||||||||

| 56 | 1422 | ||||||||||||||||||

| 60 | 1524 | ||||||||||||||||||

Size Of Carbon Steel A106 Pipe & Tube

Exhaust Pipe Size Chart In Mm

| ASTM A312 SS 304 Pipe OD mm | Pipe WT mm | in. | Sch | Kg/m |

| 13.72 | 1.65 | 1/4 | 10S | 0.50 |

| 13.72 | 2.24 | 1/4 | 40S | 0.64 |

| 13.72 | 3.02 | 1/4 | 80S | 0.81 |

| 17.15 | 1.65 | 3/8 | 10S | 0.64 |

| 17.15 | 2.31 | 3/8 | 40S | 0.86 |

| 17.15 | 3.20 | 3/8 | 80S | 1.12 |

| 21.34 | 2.11 | 1/2 | 10S | 1.02 |

| 21.34 | 2.77 | 1/2 | 40S | 1.29 |

| 21.34 | 3.73 | 1/2 | 80S | 1.65 |

| 26.67 | 2.11 | 3/4 | 10S | 1.30 |

| 26.67 | 2.87 | 3/4 | 40S | 1.71 |

| 26.67 | 3.91 | 3/4 | 80S | 2.23 |

| 33.40 | 2.77 | 1 | 10S | 2.13 |

| 33.40 | 3.38 | 1 | 40S | 2.54 |

| 33.40 | 4.55 | 1 | 80S | 3.29 |

| 33.40 | 6.352) | 1 | 160 | 4.30 |

| 42.16 | 2.77 | 1¼ | 10S | 2.73 |

| 42.16 | 3.56 | 1¼ | 40S | 3.44 |

| 42.16 | 4.85 | 1¼ | 80S | 4.53 |

| 42.16 | 6.352) | 1¼ | 160 | 5.69 |

| 48.26 | 2.77 | 1½ | 10S | 3.16 |

| 48.26 | 3.68 | 1½ | 40S | 4.11 |

| 48.26 | 5.08 | 1½ | 80S | 5.49 |

| 60.33 | 2.77 | 2 | 10S | 3.99 |

| 60.33 | 3.91 | 2 | 40S | 5.52 |

| 60.33 | 5.54 | 2 | 80S | 7.60 |

| 60.33 | 8.742) | 2 | 160 | 11.29 |

| 73.03 | 3.05 | 2½ | 10S | 5.35 |

| 73.03 | 5.16 | 2½ | 40S | 8.77 |

| 73.03 | 7.01 | 2½ | 80S | 11.59 |

| 88.90 | 3.05 | 3 | 10S | 6.56 |

| 88.90 | 5.49 | 3 | 40S | 11.47 |

| 88.90 | 7.62 | 3 | 80S | 15.51 |

| 88.90 | 11.132) | 3 | 160 | 21.67 |

| 101.60 | 3.05 | 3½ | 10S | 7.53 |

| 101.60 | 5.74 | 3½ | 40S | 13.78 |

| 101.60 | 8.08 | 3½ | 80S | 18.92 |

| 114.30 | 3.05 | 4 | 10S | 8.50 |

| 114.30 | 6.02 | 4 | 40S | 16.32 |

| 114.30 | 8.56 | 4 | 80S | 22.67 |

| 114.30 | 13.492) | 4 | 160 | 34.05 |

| 141.30 | 6.55 | 5 | 40S | 22.10 |

| 141.30 | 9.53 | 5 | 80S | 31.44 |

| 141.30 | 15.882) | 5 | 160 | 49.87 |

| 168.28 | 3.4 | 6 | 10S | 14.04 |

| 168.28 | 7.11 | 6 | 40S | 28.69 |

| 168.28 | 10.97 | 6 | 80S | 43.21 |

| 168.28 | 14.27 | 6 | 120 | 54.75 |

| 168.28 | 18.262) | 6 | 160 | 68.59 |

| 219.08 | 8.18 | 8 | 40S | 43.20 |

| 219.08 | 12.7 | 8 | 80S | 65.63 |

| 219.08 | 18.23 | 8 | 120 | 91.30 |

| 219.08 | 23.012) | 8 | 160 | 112.97 |

Erw Tube Size Chart

| Wall Thickness | Stainless Steel 304 Tube Sizes ( O.D.) Sizes ( O.D.) |

| .010 | 1/16" , 1/8" , 3/16" |

| .020 | 1/16" , 1/8" , 3/16" , 1/4" , 5/16" , 3/8" |

| .012 | 1/8" |

| .016 | 1/8" , 3/16" |

| .028 | 1/8" , 3/16" , 1/4" , 5/16" , 3/8" , 1/2" , 3/4" , 1" , 1 1/2" , 2" |

| .035 | 1/8" , 3/16" , 1/4" , 5/16" , 3/8" , 7/16" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 2" , 2 1/4" |

| .049 | 3/16" , 1/4" , 5/16" , 3/8" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/8" , 1 1/4" , 1 1/2" , 1 5/8" , 2" , 2 1/4" |

| .065 | 1/4" , 5/16" , 3/8" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 1 3/4" , 2" , 2 1/2" , 3" |

| .083 | 1/4" , 3/8" , 1/2" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 1 7/8" , 2" , 2 1/2" ,3" |

| .095 | 1/2" , 5/8" , 1" , 1 1/4" , 1 1/2" , 2" |

| .109 | 1/2" , 3/4" , 1" , 1 1/4" , 1 1/2" , 2" |

| .120 | 1/2" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 2" , 2 1/4" , 2 1/2" , 3" |

| .125 | 3/4" , 1" , 1 1/4" , 1 1/2" , 2" , 3" , 3 1/4" |

| .134 | 1" |

| .250 | 3" |

| .375 | 3 1/2" |

Weight Chart Of Carbon Steel A106 Pipe & Tube

| NPS (DN) | WEIGHT LB/FT (KG/M) | SCH | Outside Diameter IN (Milimeter) | ID | WT IN (Milimeter) |

| 32 (800) | 84.085 (126.032) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.025 (6.035) |

| 32 (800) | 95.028 (141.09) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.0281 (7.014) |

| 32 (800) | 105.069 (157.025) | 10 | 32.00 (813) | .0.0.0 | 0.0312 (7.092) |

| 32 (800) | 116.041 (173.035) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.0344 (8.074) |

| 32 (800) | 126.078 (188.083) | .0.0.0 | 32.00 (813) | STD | 0.0375 (9.053) |

| 32 (800) | 137.012 (204.009) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.0406 (10.031) |

| 32 (800) | 147.078 (220.01) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.0438 (11.013) |

| 32 (800) | 158.008 (235.029) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.0469 (11.091) |

| 32 (800) | 168.037 (250.065) | 20 | 32.00 (813) | XS | 0.05 (12.07) |

| 32 (800) | 188.087 (281.009) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.0562 (14.027) |

| 32 (800) | 209.062 (312.017) | 30 | 32.00 (813) | .0.0.0 | 0.0625 (15.088) |

| 32 (800) | 230.029 (342.094) | 40 | 32.00 (813) | .0.0.0 | 0.0688 (17.048) |

| 32 (800) | 250.055 (373.00) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.075 (19.005) |

| 32 (800) | 270.072 (402.094) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.0812 (20.062) |

| 32 (800) | 291.014 (433.052) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.0875 (22.023) |

| 32 (800) | 311.047 (463.078) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.0938 (23.083) |

| 32 (800) | 331.039 (493.035) | .0.0.0 | 32.00 (813) | .0.0.0 | 1.00 (25.04) |

| 32 (800) | 351.023 (522.08) | .0.0.0 | 32.00 (813) | .0.0.0 | 1.0062 (26.097) |

| 32 (800) | 371.031 (552.088) | .0.0.0 | 32.00 (813) | .0.0.0 | 1.0125 (28.058) |

| 32 (800) | 391.03 (582.064) | .0.0.0 | 32.00 (813) | .0.0.0 | 1.0188 (30.018) |

| 32 (800) | 410.09 (611.072) | .0.0.0 | 32.00 (813) | .0.0.0 | 1.025 (31.075) |

| 34 (850) | 90.02 (134.031) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.025 (6.035) |

| 34 (850) | 101.029 (150.088) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.0281 (7.014) |

| 34 (850) | 112.036 (167.021) | 10 | 34.00 (864) | .0.0.0 | 0.0312 (7.092) |

| 34 (850) | 123.077 (184.034) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.0344 (8.074) |

| 34 (850) | 134.079 (200.082) | .0.0.0 | 34.00 (864) | STD | 0.0375 (9.053) |

| 34 (850) | 145.08 (217.006) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.0406 (10.031) |

| 34 (850) | 157.014 (234.01) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.0438 (11.013) |

| 34 (850) | 168.011 (250.027) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.0469 (11.091) |

| 34 (850) | 179.006 (266.063) | 20 | 34.00 (864) | XS | 0.05 (12.07) |

| 34 (850) | 200.089 (299.004) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.0562 (14.027) |

| 34 (850) | 222.099 (332.014) | 30 | 34.00 (864) | .0.0.0 | 0.0625 (15.088) |

| 34 (850) | 245.00 (364.092) | 40 | 34.00 (864) | .0.0.0 | 0.0688 (17.048) |

| 34 (850) | 266.058 (396.096) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.075 (19.005) |

| 34 (850) | 288.008 (428.088) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.0812 (20.062) |

| 34 (850) | 309.084 (461.048) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.0875 (22.023) |

| 34 (850) | 331.052 (493.075) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.0938 (23.083) |

| 34 (850) | 352.077 (525.03) | .0.0.0 | 34.00 (864) | .0.0.0 | 1.00 (25.04) |

| 34 (850) | 373.094 (556.073) | .0.0.0 | 34.00 (864) | .0.0.0 | 1.0062 (26.097) |

| 34 (850) | 395.036 (588.083) | .0.0.0 | 34.00 (864) | .0.0.0 | 1.0125 (28.058) |

| 34 (850) | 416.07 (620.06) | .0.0.0 | 34.00 (864) | .0.0.0 | 1.0188 (30.018) |

| 34 (850) | 437.062 (651.065) | .0.0.0 | 34.00 (864) | .0.0.0 | 1.025 (31.075) |

| 36 (900) | 95.054 (142.014) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.025 (6.035) |

| 36 (900) | 107.03 (159.068) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0281 (7.014) |

| 36 (900) | 119.003 (176.097) | 10 | 36.00 (914) | .0.0.0 | 0.0312 (7.092) |

| 36 (900) | 131.012 (195.012) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0344 (8.074) |

| 36 (900) | 142.081 (212.057) | .0.0.0 | 36.00 (914) | STD | 0.0375 (9.053) |

| 36 (900) | 154.048 (229.077) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0406 (10.031) |

| 36 (900) | 166.051 (247.082) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0438 (11.013) |

| 36 (900) | 178.014 (264.096) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0469 (11.091) |

| 36 (900) | 189.075 (282.029) | 20 | 36.00 (914) | XS | 0.05 (12.07) |

| 36 (900) | 212.09 (316.063) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0562 (14.027) |

| 36 (900) | 236.035 (351.073) | 30 | 36.00 (914) | .0.0.0 | 0.0625 (15.088) |

| 36 (900) | 259.071 (386.047) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0688 (17.048) |

| 36 (900) | 282.062 (420.045) | 40 | 36.00 (914) | .0.0.0 | 0.075 (19.005) |

| 36 (900) | 305.044 (454.03) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0812 (20.062) |

| 36 (900) | 328.055 (488.089) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0875 (22.023) |

| 36 (900) | 351.057 (523.014) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0938 (23.083) |

| 36 (900) | 374.015 (556.062) | .0.0.0 | 36.00 (914) | .0.0.0 | 1.00 (25.04) |

| 36 (900) | 396.064 (589.098) | .0.0.0 | 36.00 (914) | .0.0.0 | 1.0062 (26.097) |

| 36 (900) | 419.042 (624.007) | .0.0.0 | 36.00 (914) | .0.0.0 | 1.0125 (28.058) |

| 36 (900) | 442.01 (657.081) | .0.0.0 | 36.00 (914) | .0.0.0 | 1.0188 (30.018) |

| 36 (900) | 464.035 (690.08) | .0.0.0 | 36.00 (914) | .0.0.0 | 1.025 (31.075) |

| 38 (950) | 125.07 (186.094) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0312 (7.092) |

| 38 (950) | 138.047 (206.011) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0344 (8.074) |

| 38 (950) | 150.083 (224.056) | .0.0.0 | 38.00 (965) | STD | 0.0375 (9.053) |

| 38 (950) | 163.016 (242.074) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0406 (10.031) |

| 38 (950) | 175.087 (261.082) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0438 (11.013) |

| 38 (950) | 188.017 (279.094) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0469 (11.091) |

| 38 (950) | 200.044 (298.026) | .0.0.0 | 38.00 (965) | XS | 0.05 (12.07) |

| 38 (950) | 224.092 (334.058) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0562 (14.027) |

| 38 (950) | 249.071 (371.07) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0625 (15.088) |

| 38 (950) | 274.042 (408.046) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0688 (17.048) |

| 38 (950) | 298.065 (444.041) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.075 (19.005) |

| 38 (950) | 322.08 (480.024) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0812 (20.062) |

| 38 (950) | 347.026 (516.085) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0875 (22.023) |

| 38 (950) | 371.063 (553.011) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0938 (23.083) |

| 38 (950) | 395.053 (588.057) | .0.0.0 | 38.00 (965) | .0.0.0 | 1.00 (25.04) |

| 38 (950) | 419.035 (623.09) | .0.0.0 | 38.00 (965) | .0.0.0 | 1.0062 (26.097) |

| 38 (950) | 443.047 (660.001) | .0.0.0 | 38.00 (965) | .0.0.0 | 1.0125 (28.058) |

| 38 (950) | 467.05 (695.077) | .0.0.0 | 38.00 (965) | .0.0.0 | 1.0188 (30.018) |

| 38 (950) | 491.007 (730.074) | .0.0.0 | 38.00 (965) | .0.0.0 | 1.025 (31.075) |

Pressure Ratings Of Carbon Steel A106 Pipe & Tube

| Schedule of Pipe | Size of Seamless Pipe (inches) | (°F) Temperature | ||||||||

| 200 | 100 | 300 | 500 | 400 | 600 | 700 | 650 | 750 | ||

| 80 | 1" | 3634 | 4213 | 3265 | 2791 | 3002 | 2659 | 2528 | 2580 | 2501 |

| 40 | 1" | 2629 | 3048 | 2362 | 2019 | 2171 | 1924 | 1824 | 1867 | 1810 |

| 40 | 1.5" | 1947 | 2257 | 1750 | 1496 | 1608 | 1425 | 1354 | 1383 | 1340 |

| 160 | 1" | 5296 | 6140 | 4759 | 4068 | 4375 | 3876 | 3684 | 3761 | 3646 |

| 160 | 1.5" | 3984 | 4619 | 3580 | 3060 | 3291 | 2916 | 2772 | 2829 | 2743 |

| 80 | 1.5" | 2744 | 3182 | 2466 | 2108 | 2267 | 2009 | 1909 | 1949 | 1889 |

| 80 | 2" | 2369 | 2747 | 2129 | 1820 | 1957 | 1734 | 1648 | 1682 | 1631 |

| 40 | 2" | 1640 | 1902 | 1474 | 1260 | 1355 | 1201 | 1141 | 1165 | 1129 |

| 40 | 3" | 1558 | 1806 | 1400 | 1196 | 1287 | 1140 | 1084 | 1106 | 1072 |

| 160 | 2" | 3880 | 4499 | 3486 | 2980 | 3205 | 2840 | 2699 | 2755 | 2671 |

| 160 | 3" | 3312 | 3840 | 2976 | 2544 | 2736 | 2424 | 2304 | 2352 | 2280 |

| 80 | 3" | 2202 | 2553 | 1979 | 1691 | 1819 | 1612 | 1532 | 1564 | 1516 |

| 80 | 4" | 1909 | 2213 | 1715 | 1466 | 1577 | 1397 | 1328 | 1355 | 1314 |

| 40 | 4" | 1321 | 1531 | 1187 | 1014 | 1091 | 967 | 919 | 938 | 909 |

| 40 | 5" | 1158 | 1342 | 1040 | 889 | 956 | 847 | 805 | 822 | 797 |

| 160 | 4" | 3106 | 3601 | 2791 | 2386 | 2566 | 2273 | 2161 | 2206 | 2138 |

| 80 | 5" | 1709 | 1981 | 1535 | 1312 | 1411 | 1250 | 1189 | 1213 | 1176 |

| 160 | 5" | 2945 | 3414 | 2646 | 2262 | 2433 | 2155 | 2049 | 2091 | 2027 |

| 80 | 6" | 1650 | 1913 | 1483 | 1267 | 1363 | 1208 | 1148 | 1172 | 1136 |

| 40 | 6" | 1052 | 1219 | 945 | 808 | 869 | 770 | 732 | 747 | 724 |

| 40 | 8" | 926 | 1073 | 832 | 711 | 765 | 678 | 644 | 657 | 637 |

| 160 | 6" | 2836 | 3289 | 2549 | 2179 | 2343 | 2076 | 1973 | 2014 | 1953 |

| 160 | 8" | 2738 | 3175 | 2460 | 2103 | 2262 | 2004 | 1905 | 1944 | 1885 |

| 80 | 8" | 1459 | 1692 | 1311 | 1121 | 1205 | 1068 | 1015 | 1036 | 1005 |

| 80 | 10" | 1388 | 1609 | 1247 | 1066 | 1147 | 1016 | 966 | 986 | 956 |

| 40 | 10" | 840 | 974 | 755 | 945 | 694 | 615 | 584 | 596 | 578 |

| 160 | 10" | 2714 | 3147 | 2439 | 2085 | 2242 | 1986 | 1880 | 1927 | 1868 |

industrial use fitting for Carbon Steel A106 Pipe & Tube

Price Of Carbon Steel A106 Pipe & Tube

| Carbon Steel Seamless Pipe | USD $3.24 - $10.84 / kg (FOB Price) on request |

| Carbon Steel Welded Pipe | USD $3.24 - $10.84 / kg (FOB Price) on request |

| Carbon Steel Hollow Pipe | USD $3.24 - $10.84 / kg (FOB Price) on request |

| Carbon Steel Tube | USD $3.24 - $10.84 / kg (FOB Price) on request |

| Carbon Steel ERW Pipe | USD $3.24 - $10.84 / kg (FOB Price) on request |

Application Of Carbon Steel A106 Pipe & Tube

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Carbon Steel A106 Pipe & Tube

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

Packing Of Carbon Steel A106 Pipe & Tube

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

ANSI B16.5 Exhaust Pipe Price List In India, Carbon Steel A106 Polished Pipe Price Per Kg, Carbon Steel A106 Air Heater Tubes Price Per Kg, ASTM A106 Carbon Steel A106 ERW Pipe Weight Chart, CS A106 Thin Wall Pipe Catalogue, CS A106 flexible corrugated pipes Catalogue, A106 Carbon Steel Fabricated Pipes Weight Calculator, ASME SA106 Carbon Steel A106 Ornamental Tubes Weight Chart, ANSI B16.5 Spiral Welded Pipe Price List In India, Carbon A106 Capillary Tube Price List, A106 Carbon Steel Electropolished Pipe Weight Calculator.

ASME SA106 Carbon Steel A106 Square Pipe Stockist in Chennai, Carbon Steel A106 Rectangular Pipe Supplier in Pune, CS A106 Thick Wall Pipe Manufacturer in Vadodara, A106 Carbon Steel Cold Drawn Seamless Tube Supplier in Hyderabad, Carbon Steel A106 IBR Pipe Supplier in Coimbatore, CS A106 Thin Wall Pipe Stockist in Gujarat, ANSI B16.5 Custom Pipe Stockist in Bangalore, Carbon Steel A106 Polished Pipe Stockist in Nashik, ASTM A106 Carbon Steel A106 ERW Pipe Supplier in Bihar, Carbon A106 Capillary Tube Exporter in Kanpur.

ASTM A106 Carbon Steel Seamless Pipe Manufacturer in USA, ASME SA106 Carbon Steel A106 Square Pipe Stockist in UAE, CS A106 Thick Wall Pipe Manufacturer in Vietnam, ANSI B16.5 Hollow Pipe Manufacturer in Singapore, ANSI B16.5 Custom Pipe Exporter in South Africa, Carbon Steel A106 IBR Pipe Supplier in Saudi Arabia, CS A106 Round Pipe Stockist in Malaysia, Carbon Steel A106 Rectangular Pipe Supplier in Qatar, Carbon A106 Welded Pipe Stockist in UK, A106 Carbon Steel Cold Drawn Seamless Tube Exporter in Indonesia, A106 Carbon Steel Tube Exporter in Kuwait.