Hastelloy X/C4/C22/C276 Instrumentation Tube Fittings

C22 Hastelloy Hollow Hex Plug, Hastelloy C4 Adaptor, Hastelloy C22 Reducing Bushing, C276 Hastelloy Pipe Plug, Hastelloy C22 Reducing Street Elbow, C4 Hastelloy Hex Reducing Nipple.

About Hastelloy X/C4/C22/C276 Instrumentation Tube Fittings

Hastelloy X is an alloy of nickel, chromium, iron, and molybdenum that exhibits remarkable resistance to carburization and nitriding. This remarkable strength also provides superior stability when facing oxidation in high-temperature and corrosive environments. Because of its beneficial properties, this alloy is the ideal option for heat exchangers, furnace components, gas turbine components, and other applications. The Hastelloy C4 alloy, composed of nickel-chromium-molybdenum, has outstanding resistance to various corrosive conditions. Remarkably resistant to pitting and crevice corrosion, this material demonstrates unparalleled stress-corrosion cracking. It offers exceptional oxidation tolerance up to 1900 °F (1037 °C), making it perfect for high temperature and aggressive applications like waste treatment or chemical processing processes as well as flue gas scrubbing activities. Due to its oxidation resistance up to 1900°F (1037 °C), it can easily withstand scorching temperatures of a scorching 1037°C.

Hastelloy C22, a nickel-chromium-molybdenum alloy, is renowned for its remarkable resistance to various corrosive conditions. With remarkable resistance to oxidation and reduction, as well as pitting and crevice corrosion, this alloy is unrivaled. Furthermore, it maintains superior protection against chloride-induced stress corrosion cracking. It can withstand halides like hydrochloric and sulfuric acids and high temperatures without deforming or deteriorating. Hastelloy C276 is an alloy made up of nickel, molybdenum, and chromium that provides remarkable protection against various corrosive conditions. This material is highly resistant to corrosion from oxidizers, reducers, and pitting; it also has exceptional protection against crevice corrosion and stress-corrosion cracking. This exceptional corrosion resistance makes the alloy suitable for use with halides like hydrochloric acid or sulfuric acids. Its astonishing strength against chloride-induced stress corrosion makes it especially valuable. Furthermore, the alloy possesses remarkable heat-resistant qualities and is regularly utilized in various industries such as pharmaceuticals, pollution control, and chemical processing.

C276 Hastelloy Pipe Plug Stockist, Hastelloy C22 Reducing Street Elbow Exporter, DIN 2.4617 Branch Tee Supplier, UNS N06022 Pipe Cap Exporter.

Specification of Hastelloy X/C4/C22/C276 Instrumentation Tube Fittings

| Size: | SEA mless:from 1/8" to 2" Welded:from 24" to 96"( or as customer requirements) |

| Pressure Rating: | 3000psi -10000psi |

| OEM Accepted | yes |

| Production Capacity: | 2000 pcs per week |

| Material | Stainless steel(ASTM A403 WP304, 304L, 316, 316L, 321. 1Cr18Ni9Ti, 00Cr19Ni10,00Cr17Ni14Mo2, etc) Alloy steel(ASTM A234 WP12, WP11, WP22, WP5, WP9, WP91, 16MnR, Cr5Mo, 12Cr1MoV, 10CrMo910, 15CrMo, 12Cr2Mo1, etc) |

| Application | Petroleum, chemical, machinery, electric power, shipbuilding, construction, etc. |

| Packing Details: |

|

Ready stock of available for Hastelloy X/C4/C22/C276 Instrumentation Tube Fittings

Equivalent Grades of Hastelloy X/C4/C22/C276 Instrumentation Tube Fittings

| STANDARD | UNS | WNR. | JIS | GOST | EN | OR |

| Hastelloy X | N06002 | 2.4665 | - | - | - | - |

| Hastelloy C4 | N10665 | 2.4617 | - | - | - | - |

| Hastelloy C22 | N06022 | 2.4602 | NW 6022 | - | NiCr21Mo14W | - |

| Hastelloy C276 | N10276 | 2.4819 | NW 0276 | ХН65МВУ | NiMo16Cr15W | ЭП760 |

Chemical Composition of Hastelloy X/C4/C22/C276 Instrumentation Tube Fittings

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| Hastelloy X | 0.05 – 0.15 | 1.0 max | 0.1 max | 0.03 max | 0.50 – 2.50 | Bal | 20.50 – 23.00 | 17.00 – 20.00 | 8.00 – 10.00 | 0.04 max |

| Hastelloy C4 | 0.02 max | 1.0 max | 0.1 max | 0.03 max | 1.0 max | Bal | 1.0 max | 2.0 max | 26 – 30 | 0.04 max |

| Hastelloy C22 | 0.010 max | 0.50 max | 0.08 max | 0.02 max | 2.50 max | 50.015 min* | 20.00 – 22.50 | 2.00 – 6.00 | 12.50 – 14.50 | 0.02 max |

| Hastelloy C276 | 0.010 max | 1.00 max | 0.08 max | 0.03 max | 2.50 max | 50.99 min* | 14.50 – 16.50 | 4.00 – 7.00 | 15.00 – 17.00 | 0.04 max |

Mechanical Properties of Hastelloy X/C4/C22/C276 Instrumentation Tube Fittings

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy X | 8.22 g/cm³ | 1355°C | 655 MPa | 240 MPa | 35% |

| Hastelloy C4 | 9.2 g/cm3 | 1370 °C (2500 ºF ) | Psi – 1,10,000 , MPa – 760 | Psi – 51000 , MPa – 350 | 40 % |

| Hastelloy C22 | 8.69 g/cm3 | 1399 °C (2550 °F) | Psi – 1,00,000 , MPa – 690 | Psi – 45000 , MPa – 310 | 45 % |

| Hastelloy C276 | 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 1,15,000 , MPa – 790 | Psi – 52,000 , MPa – 355 | 40 % |

Other Types of Hastelloy X/C4/C22/C276 Instrumentation Tube Fittings

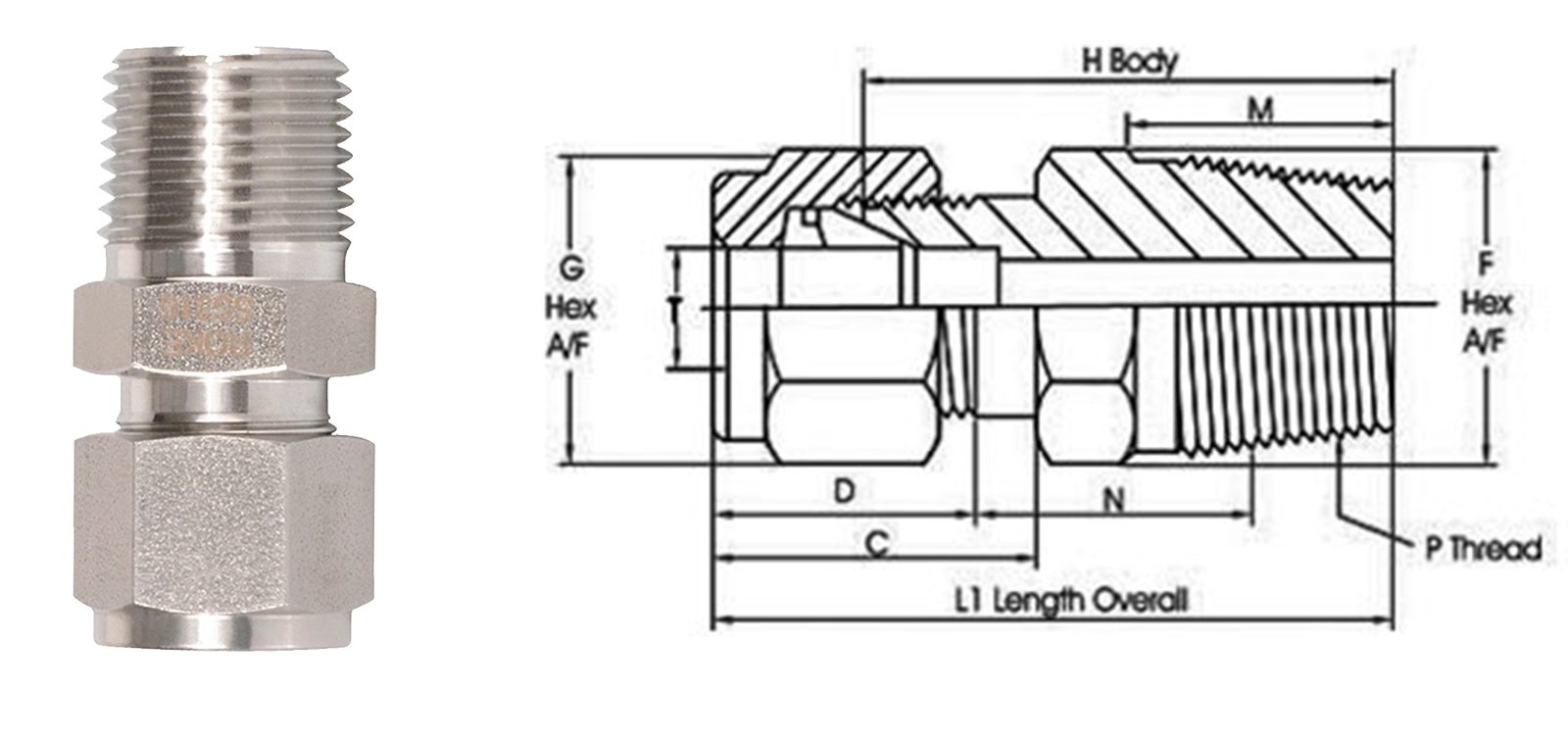

Dimensions Standard Of Hastelloy X/C4/C22/C276 Instrumentation Tube Fittings

| METRIC RANGE | Dimension in mm | |||||||||

| Part | T | P | L1 | M | C | D | F | G | H | N |

| N0 | mmo/d | Length | Body | Nut | Body | |||||

| 4mMC2 | 4 | 1/8′ | 31.35 | 9.53 | 16.67 | 14.29 | 12 | 12 | 24.21 | 10.72 |

| 4mMC4 | 4 | 1/4′ | 35.72 | 14.29 | 16.67 | 14.29 | 14 | 12 | 29.37 | 15.88 |

| 6mMC2 | 6 | 1/8′ | 33.34 | 9.53 | 18.26 | 15.88 | 14 | 14 | 25.40 | 11.11 |

| 6mMC4 | 6 | 1/4′ | 33.34 | 14.29 | 18.26 | 15.88 | 14 | 14 | 30.16 | 12.70 |

| 6mMC6 | 6 | 3/8′ | 38.89 | 14.29 | 18.26 | 15.88 | 19 | 14 | 30.96 | 13.49 |

| 6mMG8 | 6 | 1/2′ | 44.45 | 19.05 | 18.26 | 15.88 | 22 | 14 | 36.51 | 15.88 |

| 8mMC2 | 8 | 1/8′ | 34.53 | 9.53 | 19.05 | 16.67 | 14 | 17 | 26.59 | 11.51 |

| 8mM04 | 8 | 1/4′ | 39.29 | 14.29 | 19.05 | 16.67 | 14 | 17 | 31.35 | 13.10 |

| 10mM02 | 10 | 1/8′ | 35.72 | 9.53 | 19.84 | 17.46 | 17 | 19 | 27.78 | 11.91 |

| 10mMC4 | 10 | 1/4′ | 40.48 | 14.29 | 19.84 | 17.46 | 17 | 19 | 32.54 | 13.49 |

| 10mMC6 | 10 | 3/8′ | 40.48 | 14.29 | 19.84 | 17.46 | 19 | 19 | 32.54 | 13.49 |

| 10mMC8 | 10 | 1/2′ | 46.04 | 19.05 | 19.84 | 17.46 | 22 | 19 | 38.10 | 15.88 |

| 10mMC12 | 10 | 3/4′ | 46.83 | 19.05 | 19.84 | 17.46 | 27 | 19 | 38.89 | 15.08 |

| 12mMC4 | 12 | 1/4′ | 43.66 | 14.29 | 22.23 | 23.02 | 22 | 22 | 33.34 | 11.11 |

| 12mMC6 | 12 | 3/8′ | 43.66 | 14.29 | 22.23 | 23.02 | 22 | 22 | 33.34 | 11.11 |

| 12mMC8 | 12 | 1/2′ | 48.42 | 19.05 | 22.23 | 23.02 | 22 | 22 | 38.10 | 12.70 |

| 12mM012 | 12 | 3/4′ | 49.21 | 19.05 | 22.23 | 23.02 | 27 | 22 | 38.89 | 11.91 |

| 16mMC6 | 16 | 3/8′ | 44.45 | 14.29 | 22.23 | 24.61 | 24 | 27 | 34.13 | 10.32 |

| 16mMC8 | 16 | 1/2′ | 49.21 | 19.05 | 22.23 | 24.61 | 24 | 27 | 38.89 | 11.91 |

| 16mMC12 | 16 | 3/4′ | 49.21 | 19.05 | 22.23 | 24.61 | 27 | 27 | 38.89 | 10.32 |

| 18mMC8 | 18 | 1/2′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 13.49 |

| 18mMC12 | 18 | 3/4′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 10.32 |

| 18mMC16 | 18 | 1" | 56.36 | 23.81 | 22.23 | 24.61 | 36 | 30 | 46.40 | 14.29 |

| 20mMC8 | 20 | 1/2′ | 50.80 | 19.05 | 22.23 | 24.60 | 27 | 30 | 40.48 | 13.49 |

| 20mM012 | 20 | 3/4′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 10.32 |

| 20mM016 | 20 | 1" | 56.36 | 23.81 | 22.23 | 14.61 | 36 | 30 | 46.04 | 14.39 |

| 25mMC12 | 25 | 3/4′ | 57.15 | 19.05 | 26.19 | 30.96 | 36 | 41 | 45.24 | 11.91 |

| 25mMC16 | 25 | 1" | 61.91 | 23.81 | 26.19 | 30.96 | 36 | 41 | 50.01 | 13.49 |

| METRIC RANGE | Dimention in Inches | |||||||||

| Part | T | P | L1 | M | C | D | F | G | H | N |

| N0 | mmo/d | Length | Body | Nut | Body | |||||

| 1MC1 | 1/16 | 1/16 | .94 | .38 | .44 | .34 | 5/16 | 5/16 | .78 | .34 |

| 1MC2 | 1/16 | 1/8 | 1.00 | .38 | .44 | .34 | 1/2 | 5/16 | .84 | .41 |

| 2MC1 | 1/8 | 1/16 | 1.19 | .38 | .63 | .53 | 1/2 | 7/16 | .91 | .41 |

| 2MC2 | 1/8 | 1/8 | 1.19 | .38 | .63 | .53 | 1/2 | 7/16 | .91 | .41 |

| 2MC4 | 1/8 | 1/4 | 1.41 | .56 | .63 | .53 | 9/16 | 7/16 | 1.13 | .50 |

| 3MC2 | 3/16 | 1/8 | 1.21 | .38 | .63 | .54 | 7/16 | 1/2 | .95 | .43 |

| 3MC4 | 3/16 | 1/4 | 1.42 | .38 | .63 | .54 | 9.16 | 1/2 | 1.16 | .54 |

| 4MC1 | 1/4 | 1/16 | 1.29 | .56 | .70 | .60 | 1/2 | 9/16 | 1.00 | .46 |

| 4MC2 | 1/4 | 1/8 | 1.29 | .56 | .70 | .60 | 1/2 | 9/16 | 1.00 | .45 |

| 4MC4 | 1/4 | 1/4 | 1.50 | .75 | .72 | .63 | 9/16 | 9/16 | 1.19 | .50 |

| 4MC6 | 1/4 | 3/8 | 1.51 | .38 | .70 | .60 | 11/16 | 9/16 | 1.19 | .56 |

| 4MC8 | 1/4 | 1/2 | 1.73 | .56 | .70 | .60 | 7/8 | 9/16 | 1.44 | .67 |

| 5MC2 | 5/16 | 1/8 | 1.34 | .38 | .73 | .64 | 9/16 | 5/8 | 1.05 | .46 |

| 5MC4 | 5/16 | 1/4 | 1.52 | .56 | .73 | .64 | 9/16 | 5/8 | 1.23 | .54 |

| 6MC2 | 3/8 | 1/8 | 1.38 | .56 | .76 | .66 | 5/8 | 11/16 | 1.09 | .48 |

| 6MC4 | 3/8 | 1/4 | 1.57 | .75 | .76 | .66 | 5/8 | 11/16 | 1.28 | .57 |

| 6MC6 | 3/B | 3/8 | 1.57 | .75 | .76 | .66 | 11/16 | 11/16 | 1.28 | .56 |

| 6MC8 | 3/B | 1/2 | 1.79 | .56 | .76 | .66 | 7/8 | 11/16 | 1.50 | .67 |

| 6MC12 | 3/8 | 3/4 | 1.82 | .56 | .76 | .66 | 1-1/16 | 11/16 | 1.53 | .68 |

| 8MC4 | 1/2 | 1/4 | 1.17 | .75 | .86 | .90 | 13/16 | 7/8 | 1.31 | .47 |

| 8MC6 | 1/2 | 3/8 | 1.71 | .75 | .86 | .90 | 13/16 | 7/8 | 1.31 | .46 |

| 8MC8 | 1/2 | 1/2 | 1.90 | .56 | .86 | .90 | 7/8 | 7/8 | 1.50 | .54 |

| 8MC12 | 1/2 | 3/4 | 1.93 | .75 | .86 | .90 | 1-1/16 | 7/8 | 1.53 | .55 |

| 10MC6 | 5/8 | 3/8 | 1.74 | .56 | .86 | .96 | 15/16 | 1 | 1.34 | .43 |

| 10MC8 | 5/8 | 1/2 | 1.93 | .75 | .86 | .96 | 15/16 | 1 | 1.53 | .51 |

| 10MC12 | 5/B | 3/4 | 1.93 | .75 | .86 | .96 | 1-1/16 | 1 | 1.53 | .49 |

| 12MC8 | 3/4 | 1/2 | 1.99 | .75 | .86 | .96 | 1-1/16 | 1-1/8 | 1.59 | .57 |

| 12MC12 | 3/4 | 3/4 | 1.99 | .75 | .86 | .96 | 1-1/16 | 1-1/18 | 1.59 | .55 |

| 12MC16 | 3/4 | 1 | 2.21 | .94 | .86 | .96 | 1-3/16 | 1-1/8 | 1.81 | .68 |

| 16MC12 | 1 | 3/4 | 2.26 | .75 | 1.04 | 1.23 | 1-3/8 | 1-1/2 | 1.78 | .55 |

| 16MC16 | 1 | 1 | 2.45 | .94 | 1.04 | 1.23 | 1-3/8 | 1-1/2 | 1.97 | .65 |

industrial use fitting for Hastelloy X/C4/C22/C276 Instrumentation Tube Fittings

Price Of Hastelloy X/C4/C22/C276 Instrumentation Tube Fittings

| High Nickel Alloys Male Connector | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Hex Nipple | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Reducing Coupling | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Adaptor | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Bushing | USD $8.11 - $20.21 / Piece (FOB Price) on request |

Application Of Hastelloy X/C4/C22/C276 Instrumentation Tube Fittings

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Hastelloy X/C4/C22/C276 Instrumentation Tube Fittings

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

Packing Of Hastelloy X/C4/C22/C276 Instrumentation Tube Fittings

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

Hastelloy C4 Union Ball Joint Price List, C22 Hastelloy Reducing Adaptor At Factory Price, DIN 2.4602 Tube To Hose Connector Price List In India, UNS N06022 Pipe Cap Weight Chart, Hastelloy C276 Hex Nipple Price Per Kg, C4 Hastelloy Male Tee Weight Calculator, DIN 2.4819 Hex Plug Catalogue, UNS N10665 Street Run Tee Price List In India, DIN 2.4617 Hex Coupling Catalogue, DIN 2.4602 Gauge Adaptor Price List, ASTM B564 Hastelloy X Male Connector Weight Chart, UNS N10665 Hex Long Nipple Price List In India, Hastelloy C4 Adaptor At Factory Price, Hastelloy C22 Reducing Street Elbow Price List.

DIN 2.4602 Tube To Hose Connector Supplier in Kolkata, ASTM B564 Hastelloy X Street Elbow Supplier in Bihar, UNS N06022 Pipe Cap Stockist in Bangalore, Hastelloy C276 Hex Nipple Supplier in Coimbatore, Hastelloy C22 Male Elbow Stockist in Pimpri-Chinchwad, C4 Hastelloy Male Tee Stockist in Kerla, UNS N10276 Female Elbow Manufacturer in Daman, ASTM B564 Hastelloy X Male Connector Manufacturer in Bengaluru, C276 Hastelloy Pipe Plug Stockist in Bharuch, DIN 2.4602 Gauge Adaptor Manufacturer in Vadodara, UNS N10665 Hex Long Nipple Manufacturer in Mumbai.

ASME SB564 Hastelloy C276 Female Cross Exporter in Lebanon, UNS N06022 Male Hose Connector Stockist in Libya, Hastelloy C4 Adaptor Supplier in Qatar, C22 Hastelloy Reducing Adaptor Exporter in Indonesia, ASME SB564 Hastelloy C276 Reducing Coupling Stockist in UAE, C276 Hastelloy Pipe Plug Stockist in Australia, DIN 2.4602 Gauge Adaptor Manufacturer in Vietnam, DIN 2.4617 Branch Tee Supplier in Jordan, Hastelloy C276 Hex Nipple Supplier in Saudi Arabia, DIN 2.4602 Tube To Hose Connector Supplier in Algeria, UNS N10276 Female Elbow Manufacturer in Italy.