Duplex 2205/ UNS 32205/ UNS 31803 Pipe & Tube

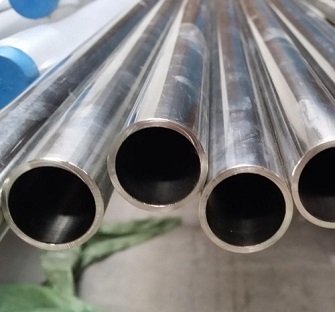

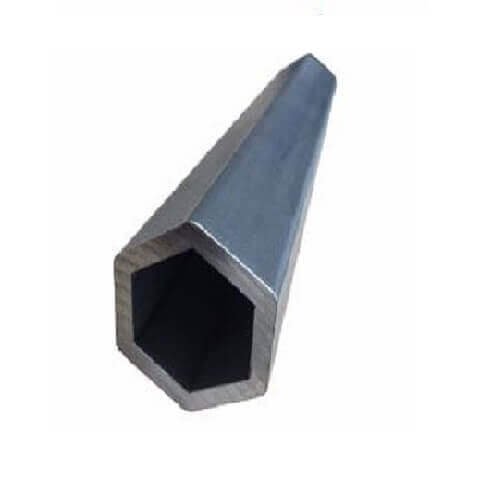

ASTM A790 Duplex 2205 ERW Pipe, Duplex 2205 Polished Pipe, Duplex 32205 IBR Pipe, Duplex 32205 Slot Round Pipe, UNS S220503 Hexagonal Tube, Duplex 32205 Rectangular Pipe, ASME SA790 Duplex 2205 Square Pipe.

About Duplex 2205/ UNS 32205/ UNS 31803 Pipe & Tube

DUPLEX 2205 (UNS 32205) and UNS 31803 are two of the most popular duplex stainless steel grades used in the piping and tubing industry. Both grades offer a unique combination of high strength and excellent corrosion resistance, making them suitable for a wide range of applications.

DUPLEX 2205 (UNS 32205) is a duplex stainless steel that is composed of 22% chromium, 3% molybdenum, and 5-6% nickel. It offers a high strength-to-weight ratio, making it ideal for use in applications where weight is a concern, such as in the oil and gas industry. The duplex structure of this grade provides excellent resistance to stress corrosion cracking, making it suitable for use in harsh environments. Additionally, DUPLEX 2205 has a high resistance to chloride pitting and crevice corrosion, making it an ideal choice for use in marine and coastal environments. UNS 31803 is another popular duplex stainless steel grade that is composed of 21% chromium, 3% molybdenum, and 4-5% nickel. It offers similar properties to DUPLEX 2205, including high strength, excellent corrosion resistance, and good resistance to stress corrosion cracking. However, UNS 31803 has a lower nickel content than DUPLEX 2205, making it more cost-effective for certain applications. Additionally, UNS 31803 has a higher resistance to sulfuric acid and other acidic environments, making it suitable for use in the chemical industry.

Both DUPLEX 2205 and UNS 31803 are available in both seamless and welded forms, as well as ERW (Electric Resistance Welded) forms. Seamless pipes and tubes are produced by extrusion or drawing, resulting in a smooth surface with no weld seams. Welded pipes and tubes are produced by welding a steel strip or plate into a tube shape, resulting in a weld seam on the surface. ERW pipes and tubes are produced by welding a steel strip or plate into a tube shape using electric resistance welding, resulting in a smooth surface with no weld seams. In terms of properties, both DUPLEX 2205 and UNS 31803 offer high strength and excellent corrosion resistance. Both grades have a high resistance to stress corrosion cracking, making them suitable for use in harsh environments. Additionally, both grades have a high resistance to chloride pitting and crevice corrosion, making them suitable for use in marine and coastal environments.

Our company packs DUPLEX 2205/UNS 32205/UNS 31803 pipes and tubes in wooden crates or pallets, with plastic wrapping and end caps to protect the surface during transportation. The crates or pallets are then shrink-wrapped for added stability and security during shipping. Our packaging meets industry standards and ensures that the product arrives at the destination in perfect condition.

DIN 1.4462 Thin Wall Pipe Stockist, Duplex 2205 Polished Pipe Stockist, UNS S31803 Spiral Welded Pipe Stockist, UNS S31803 Hollow Pipe Manufacturer.

Specification of Duplex 2205/ UNS 32205/ UNS 31803 Pipe & Tube

| Specifications | ASTM A790 / ASME SA790 |

| Dimensional specification | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| Size | 1 / 8" NB - 24" NB |

| Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock |

| Manufacturing Shapes | Hydraulic, Round, Square, Hex, Honed |

| Manufacturing Techniques | Normalized & as Rolled |

| Schedule Thickness Range | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| End Types | Plain End, Beveled End, Treaded One End, TBE (Treaded Both Ends) |

| Surface Finish | No.1, No.4, No.8 Mirror Finish, 2B |

| Value Added Services | Cutting, Beveling, Polishing, Threading, Destructive, Non Destructive, Ultrasonic Testing |

| Inspection and Test Reports | EN 10204 3.1, Mill Test Certificates, Chemical Reports, PMI Test Reports, Mechanical Reports, Third Party Inspection, NABL Approved Lab, Visual Inspection, Destructive Test and Non Destructive Test Reports |

| Outside Finish | 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Seamless Pipes, Finish as per customer Requirements |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Heat Treatment | Normalized, Normalized & Tempered |

| Packing of Seamless Pipes | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be on request |

Ready stock of available for Duplex 2205/ UNS 32205/ UNS 31803 Pipe & Tube

Equivalent Grades of Duplex 2205/ UNS 32205/ UNS 31803 Pipe & Tube

| STANDARD | WERKSTOFF NR. | UNS |

| Duplex 2205 | 1.4462 | S31803 / S32205 |

| Duplex S32205 | 1.4462 | S31803 / S32205 |

| Duplex S31803 | 1.4462 | S31803 / S32205 |

Chemical Composition of Duplex 2205/ UNS 32205/ UNS 31803 Pipe & Tube

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| 2205 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21.0 – 23.0 | 2.50 - 3.50 | 4.50 – 6.50 | 0.8 – 0.20 | 63.54 min |

| 32205 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21.0 – 23.0 | 2.50 - 3.50 | 4.50 – 6.50 | 0.8 – 0.20 | 63.54 min |

| 31803 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21.0 – 23.0 | 2.50 - 3.50 | 4.50 – 6.50 | 0.8 – 0.20 | 63.54 min |

Mechanical Properties of Duplex 2205/ UNS 32205/ UNS 31803 Pipe & Tube

| Grades | Density (g/cm 3) | Melting Point | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

| 2205 | 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000 , MPa – 800 | Psi – 80000 , MPa – 550 | 15 % |

| 32205 | 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000 , MPa – 800 | Psi – 80000 , MPa – 550 | 15 % |

| 31803 | 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000 , MPa – 800 | Psi – 80000 , MPa – 550 | 15 % |

Other Types of Duplex 2205/ UNS 32205/ UNS 31803 Pipe & Tube

Dimensions Standard Of Duplex 2205/ UNS 32205/ UNS 31803 Pipe & Tube

| Nominal Pipe Size | Outside Diameter (mm) | Nominal Wall Thickness Schedule | |||||||||||||||||

| NPS | DN | OD | SCH5s | SCHl0s | SCH 10 | SCH 20 | SCH 30 | SCH40s | SCH STD | SCH 40 | SCH 60 | SCH80s | SCH XS | SCH 80 | SCH 100 | SCH 120 | SCH 140 | SCH 160 | SCH XXS |

| 1/8 | 6 | 10.3 | 1.24 | 1.73 | 1.73 | 1.73 | 2.41 | 2.41 | 2.41 | ||||||||||

| 1/4 | 8 | 13.7 | 1.65 | 2.24 | 2.24 | 2.24 | 3.02 | 3.02 | 3.02 | ||||||||||

| 3/8 | 10 | 17.1 | 1.65 | 2.31 | 2,31 | 2.31 | 3.20 | 3.20 | 3.20 | ||||||||||

| 1/2 | 15 | 21.3 | 1.65 | 2.11 | 2.77 | 2.77 | 2.77 | 3.73 | 3.73 | 3.73 | 4.78 | 7.47 | |||||||

| 3/4 | 20 | 26.7 | 1.65 | 2.11 | 2.87 | 2.87 | 2.87 | 3.91 | 3.91 | 3.91 | 5.56 | 7.82 | |||||||

| 1 | 25 | 33.4 | 1.65 | 2.77 | 3.38 | 3.38 | 3.38 | 4.55 | 4.55 | 4.55 | 6.35 | 9.09 | |||||||

| 1 1/4 | 32 | 42.2 | 1.65 | 2.77 | 3.56 | 3.56 | 3,56 | 4.85 | 4.85 | 4.85 | 6.35 | 9.70 | |||||||

| 1 1/2 | 40 | 48.3 | 1.65 | 2.77 | 3.68 | 3.68 | 3.68 | 5.08 | 5.08 | 5.08 | 7.14 | 10.15 | |||||||

| 2 | 50 | 60.3 | 1.65 | 2.77 | 3.91 | 3.91 | 3.91 | 5.54 | 5.54 | 5.54 | 8.74 | 11.07 | |||||||

| 2 1/2 | 65 | 73 | 2.11 | 3.05 | 5.16 | 5.16 | 5.16 | 7.01 | 7.01 | 7.01 | 9.53 | 14.02 | |||||||

| 3 | 80 | 88.9 | 2.11 | 3.05 | 5.49 | 5.49 | 5.49 | 7.62 | 7.62 | 7.62 | 11.13 | 15.24 | |||||||

| 3 1/2 | 90 | 101.6 | 2.11 | 3.05 | 5.74 | 5.74 | 5.74 | 8.08 | 8.08 | 8.08 | |||||||||

| 4 | 100 | 114.3 | 2.11 | 3.05 | 6.02 | 6.02 | 6.02 | 8.56 | 8.56 | 8.56 | 11.13 | 13.49 | 17.12 | ||||||

| 5 | 125 | 141.3 | 2.77 | 3.40 | 6.55 | 6.55 | 6.55 | 9.53 | 9,53 | 9.53 | 12.70 | 15.88 | 19.05 | ||||||

| 6 | 150 | 168.3 | 2.77 | 3.40 | 7.11 | 7.11 | 7.11 | 10.97 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | ||||||

| 8 | 200 | 219.1 | 2.77 | 3.76 | 6.35 | 7.04 | 8.18 | 8.18 | 8.18 | 10.31 | 12.70 | 12.70 | 12.70 | 15.09 | 18.26 | 20.62 | 23.01 | 22.23 | |

| 10 | 250 | 273.1 | 3.40 | 4.19 | 6.35 | 7.80 | 9.27 | 9.27 | 9.27 | 12.70 | 12.70 | 12.70 | 15.09 | 18.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 12 | 300 | 323.9 | 3.96 | 4.57 | 6.35 | 8.38 | 9.53 | 9.53 | 10.31 | 14.27 | 12.70 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 14 | 350 | 355.6 | 3.96 | 4.78 | 6.35 | 7.92 | 9.53 | 9.53 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |||

| 16 | 400 | 406.4 | 4.19 | 4.78 | 6.35 | 7.92 | 9.53 | 9.53 | 12.70 | i6.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |||

| 18 | 450 | 457.2 | 4.19 | 4.78 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39,67 | 45.24 | |||

| 20 | 500 | 508 | 4.78 | 5.54 | 6.35 | 9.53 | 12.70 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |||

| 22 | 559 | 4.78 | 5.54 | 6.35 | 9.53 | 12.70 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | |||||

| 24 | 600 | 610 | 5.54 | 6.35 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |||

| 26 | 660 | 7.92 | 12.70 | 9.53 | 12.70 | ||||||||||||||

| 28 | 700 | 711 | 7.92 | 12.70 | 15.88 | 9.53 | 12.70 | ||||||||||||

| 30 | 762 | 6.35 | 7.92 | 7.92 | 12.70 | 15.88 | 9.53 | 12.70 | |||||||||||

| 32 | 800 | 813 | 7.92 | 12.70 | 15.88 | 9.53 | 17.48 | 12.70 | |||||||||||

| 34 | 884 | 7.92 | 12.70 | 15.88 | 9.53 | 17.48 | 12.70 | ||||||||||||

| 36 | 900 | 914 | 7.92 | 12.70 | 15.88 | 9.53 | 19.05 | 12.70 | |||||||||||

| 38 | 965 | 9.53 | 12.70 | ||||||||||||||||

| 40 | 1000 | 1016 | 9.53 | 12.70 | |||||||||||||||

| 42 | 1067 | 12.70 | 15.88 | 9.53 | 19.05 | 12.70 | |||||||||||||

| 44 | 1100 | 1118 | 9.53 | 12.70 | |||||||||||||||

| 46 | 1168 | 9.53 | 12.70 | ||||||||||||||||

| 48 | 1200 | 1219 | 9.53 | 12.70 | |||||||||||||||

| 52 | 1321 | ||||||||||||||||||

| 56 | 1422 | ||||||||||||||||||

| 60 | 1524 | ||||||||||||||||||

Size Of Duplex 2205/ UNS 32205/ UNS 31803 Pipe & Tube

Exhaust Pipe Size Chart In Mm

| ASTM A312 SS 304 Pipe OD mm | Pipe WT mm | in. | Sch | Kg/m |

| 13.72 | 1.65 | 1/4 | 10S | 0.50 |

| 13.72 | 2.24 | 1/4 | 40S | 0.64 |

| 13.72 | 3.02 | 1/4 | 80S | 0.81 |

| 17.15 | 1.65 | 3/8 | 10S | 0.64 |

| 17.15 | 2.31 | 3/8 | 40S | 0.86 |

| 17.15 | 3.20 | 3/8 | 80S | 1.12 |

| 21.34 | 2.11 | 1/2 | 10S | 1.02 |

| 21.34 | 2.77 | 1/2 | 40S | 1.29 |

| 21.34 | 3.73 | 1/2 | 80S | 1.65 |

| 26.67 | 2.11 | 3/4 | 10S | 1.30 |

| 26.67 | 2.87 | 3/4 | 40S | 1.71 |

| 26.67 | 3.91 | 3/4 | 80S | 2.23 |

| 33.40 | 2.77 | 1 | 10S | 2.13 |

| 33.40 | 3.38 | 1 | 40S | 2.54 |

| 33.40 | 4.55 | 1 | 80S | 3.29 |

| 33.40 | 6.352) | 1 | 160 | 4.30 |

| 42.16 | 2.77 | 1¼ | 10S | 2.73 |

| 42.16 | 3.56 | 1¼ | 40S | 3.44 |

| 42.16 | 4.85 | 1¼ | 80S | 4.53 |

| 42.16 | 6.352) | 1¼ | 160 | 5.69 |

| 48.26 | 2.77 | 1½ | 10S | 3.16 |

| 48.26 | 3.68 | 1½ | 40S | 4.11 |

| 48.26 | 5.08 | 1½ | 80S | 5.49 |

| 60.33 | 2.77 | 2 | 10S | 3.99 |

| 60.33 | 3.91 | 2 | 40S | 5.52 |

| 60.33 | 5.54 | 2 | 80S | 7.60 |

| 60.33 | 8.742) | 2 | 160 | 11.29 |

| 73.03 | 3.05 | 2½ | 10S | 5.35 |

| 73.03 | 5.16 | 2½ | 40S | 8.77 |

| 73.03 | 7.01 | 2½ | 80S | 11.59 |

| 88.90 | 3.05 | 3 | 10S | 6.56 |

| 88.90 | 5.49 | 3 | 40S | 11.47 |

| 88.90 | 7.62 | 3 | 80S | 15.51 |

| 88.90 | 11.132) | 3 | 160 | 21.67 |

| 101.60 | 3.05 | 3½ | 10S | 7.53 |

| 101.60 | 5.74 | 3½ | 40S | 13.78 |

| 101.60 | 8.08 | 3½ | 80S | 18.92 |

| 114.30 | 3.05 | 4 | 10S | 8.50 |

| 114.30 | 6.02 | 4 | 40S | 16.32 |

| 114.30 | 8.56 | 4 | 80S | 22.67 |

| 114.30 | 13.492) | 4 | 160 | 34.05 |

| 141.30 | 6.55 | 5 | 40S | 22.10 |

| 141.30 | 9.53 | 5 | 80S | 31.44 |

| 141.30 | 15.882) | 5 | 160 | 49.87 |

| 168.28 | 3.4 | 6 | 10S | 14.04 |

| 168.28 | 7.11 | 6 | 40S | 28.69 |

| 168.28 | 10.97 | 6 | 80S | 43.21 |

| 168.28 | 14.27 | 6 | 120 | 54.75 |

| 168.28 | 18.262) | 6 | 160 | 68.59 |

| 219.08 | 8.18 | 8 | 40S | 43.20 |

| 219.08 | 12.7 | 8 | 80S | 65.63 |

| 219.08 | 18.23 | 8 | 120 | 91.30 |

| 219.08 | 23.012) | 8 | 160 | 112.97 |

Erw Tube Size Chart

| Wall Thickness | Stainless Steel 304 Tube Sizes ( O.D.) Sizes ( O.D.) |

| .010 | 1/16" , 1/8" , 3/16" |

| .020 | 1/16" , 1/8" , 3/16" , 1/4" , 5/16" , 3/8" |

| .012 | 1/8" |

| .016 | 1/8" , 3/16" |

| .028 | 1/8" , 3/16" , 1/4" , 5/16" , 3/8" , 1/2" , 3/4" , 1" , 1 1/2" , 2" |

| .035 | 1/8" , 3/16" , 1/4" , 5/16" , 3/8" , 7/16" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 2" , 2 1/4" |

| .049 | 3/16" , 1/4" , 5/16" , 3/8" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/8" , 1 1/4" , 1 1/2" , 1 5/8" , 2" , 2 1/4" |

| .065 | 1/4" , 5/16" , 3/8" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 1 3/4" , 2" , 2 1/2" , 3" |

| .083 | 1/4" , 3/8" , 1/2" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 1 7/8" , 2" , 2 1/2" ,3" |

| .095 | 1/2" , 5/8" , 1" , 1 1/4" , 1 1/2" , 2" |

| .109 | 1/2" , 3/4" , 1" , 1 1/4" , 1 1/2" , 2" |

| .120 | 1/2" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 2" , 2 1/4" , 2 1/2" , 3" |

| .125 | 3/4" , 1" , 1 1/4" , 1 1/2" , 2" , 3" , 3 1/4" |

| .134 | 1" |

| .250 | 3" |

| .375 | 3 1/2" |

Weight Chart Of Duplex 2205/ UNS 32205/ UNS 31803 Pipe & Tube

| NPS (DN) | WEIGHT LB/FT (KG/M) | SCH | Outside Diameter IN (Milimeter) | ID | WT IN (Milimeter) |

| 32 (800) | 84.085 (126.032) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.025 (6.035) |

| 32 (800) | 95.028 (141.09) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.0281 (7.014) |

| 32 (800) | 105.069 (157.025) | 10 | 32.00 (813) | .0.0.0 | 0.0312 (7.092) |

| 32 (800) | 116.041 (173.035) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.0344 (8.074) |

| 32 (800) | 126.078 (188.083) | .0.0.0 | 32.00 (813) | STD | 0.0375 (9.053) |

| 32 (800) | 137.012 (204.009) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.0406 (10.031) |

| 32 (800) | 147.078 (220.01) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.0438 (11.013) |

| 32 (800) | 158.008 (235.029) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.0469 (11.091) |

| 32 (800) | 168.037 (250.065) | 20 | 32.00 (813) | XS | 0.05 (12.07) |

| 32 (800) | 188.087 (281.009) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.0562 (14.027) |

| 32 (800) | 209.062 (312.017) | 30 | 32.00 (813) | .0.0.0 | 0.0625 (15.088) |

| 32 (800) | 230.029 (342.094) | 40 | 32.00 (813) | .0.0.0 | 0.0688 (17.048) |

| 32 (800) | 250.055 (373.00) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.075 (19.005) |

| 32 (800) | 270.072 (402.094) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.0812 (20.062) |

| 32 (800) | 291.014 (433.052) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.0875 (22.023) |

| 32 (800) | 311.047 (463.078) | .0.0.0 | 32.00 (813) | .0.0.0 | 0.0938 (23.083) |

| 32 (800) | 331.039 (493.035) | .0.0.0 | 32.00 (813) | .0.0.0 | 1.00 (25.04) |

| 32 (800) | 351.023 (522.08) | .0.0.0 | 32.00 (813) | .0.0.0 | 1.0062 (26.097) |

| 32 (800) | 371.031 (552.088) | .0.0.0 | 32.00 (813) | .0.0.0 | 1.0125 (28.058) |

| 32 (800) | 391.03 (582.064) | .0.0.0 | 32.00 (813) | .0.0.0 | 1.0188 (30.018) |

| 32 (800) | 410.09 (611.072) | .0.0.0 | 32.00 (813) | .0.0.0 | 1.025 (31.075) |

| 34 (850) | 90.02 (134.031) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.025 (6.035) |

| 34 (850) | 101.029 (150.088) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.0281 (7.014) |

| 34 (850) | 112.036 (167.021) | 10 | 34.00 (864) | .0.0.0 | 0.0312 (7.092) |

| 34 (850) | 123.077 (184.034) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.0344 (8.074) |

| 34 (850) | 134.079 (200.082) | .0.0.0 | 34.00 (864) | STD | 0.0375 (9.053) |

| 34 (850) | 145.08 (217.006) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.0406 (10.031) |

| 34 (850) | 157.014 (234.01) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.0438 (11.013) |

| 34 (850) | 168.011 (250.027) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.0469 (11.091) |

| 34 (850) | 179.006 (266.063) | 20 | 34.00 (864) | XS | 0.05 (12.07) |

| 34 (850) | 200.089 (299.004) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.0562 (14.027) |

| 34 (850) | 222.099 (332.014) | 30 | 34.00 (864) | .0.0.0 | 0.0625 (15.088) |

| 34 (850) | 245.00 (364.092) | 40 | 34.00 (864) | .0.0.0 | 0.0688 (17.048) |

| 34 (850) | 266.058 (396.096) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.075 (19.005) |

| 34 (850) | 288.008 (428.088) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.0812 (20.062) |

| 34 (850) | 309.084 (461.048) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.0875 (22.023) |

| 34 (850) | 331.052 (493.075) | .0.0.0 | 34.00 (864) | .0.0.0 | 0.0938 (23.083) |

| 34 (850) | 352.077 (525.03) | .0.0.0 | 34.00 (864) | .0.0.0 | 1.00 (25.04) |

| 34 (850) | 373.094 (556.073) | .0.0.0 | 34.00 (864) | .0.0.0 | 1.0062 (26.097) |

| 34 (850) | 395.036 (588.083) | .0.0.0 | 34.00 (864) | .0.0.0 | 1.0125 (28.058) |

| 34 (850) | 416.07 (620.06) | .0.0.0 | 34.00 (864) | .0.0.0 | 1.0188 (30.018) |

| 34 (850) | 437.062 (651.065) | .0.0.0 | 34.00 (864) | .0.0.0 | 1.025 (31.075) |

| 36 (900) | 95.054 (142.014) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.025 (6.035) |

| 36 (900) | 107.03 (159.068) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0281 (7.014) |

| 36 (900) | 119.003 (176.097) | 10 | 36.00 (914) | .0.0.0 | 0.0312 (7.092) |

| 36 (900) | 131.012 (195.012) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0344 (8.074) |

| 36 (900) | 142.081 (212.057) | .0.0.0 | 36.00 (914) | STD | 0.0375 (9.053) |

| 36 (900) | 154.048 (229.077) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0406 (10.031) |

| 36 (900) | 166.051 (247.082) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0438 (11.013) |

| 36 (900) | 178.014 (264.096) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0469 (11.091) |

| 36 (900) | 189.075 (282.029) | 20 | 36.00 (914) | XS | 0.05 (12.07) |

| 36 (900) | 212.09 (316.063) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0562 (14.027) |

| 36 (900) | 236.035 (351.073) | 30 | 36.00 (914) | .0.0.0 | 0.0625 (15.088) |

| 36 (900) | 259.071 (386.047) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0688 (17.048) |

| 36 (900) | 282.062 (420.045) | 40 | 36.00 (914) | .0.0.0 | 0.075 (19.005) |

| 36 (900) | 305.044 (454.03) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0812 (20.062) |

| 36 (900) | 328.055 (488.089) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0875 (22.023) |

| 36 (900) | 351.057 (523.014) | .0.0.0 | 36.00 (914) | .0.0.0 | 0.0938 (23.083) |

| 36 (900) | 374.015 (556.062) | .0.0.0 | 36.00 (914) | .0.0.0 | 1.00 (25.04) |

| 36 (900) | 396.064 (589.098) | .0.0.0 | 36.00 (914) | .0.0.0 | 1.0062 (26.097) |

| 36 (900) | 419.042 (624.007) | .0.0.0 | 36.00 (914) | .0.0.0 | 1.0125 (28.058) |

| 36 (900) | 442.01 (657.081) | .0.0.0 | 36.00 (914) | .0.0.0 | 1.0188 (30.018) |

| 36 (900) | 464.035 (690.08) | .0.0.0 | 36.00 (914) | .0.0.0 | 1.025 (31.075) |

| 38 (950) | 125.07 (186.094) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0312 (7.092) |

| 38 (950) | 138.047 (206.011) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0344 (8.074) |

| 38 (950) | 150.083 (224.056) | .0.0.0 | 38.00 (965) | STD | 0.0375 (9.053) |

| 38 (950) | 163.016 (242.074) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0406 (10.031) |

| 38 (950) | 175.087 (261.082) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0438 (11.013) |

| 38 (950) | 188.017 (279.094) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0469 (11.091) |

| 38 (950) | 200.044 (298.026) | .0.0.0 | 38.00 (965) | XS | 0.05 (12.07) |

| 38 (950) | 224.092 (334.058) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0562 (14.027) |

| 38 (950) | 249.071 (371.07) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0625 (15.088) |

| 38 (950) | 274.042 (408.046) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0688 (17.048) |

| 38 (950) | 298.065 (444.041) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.075 (19.005) |

| 38 (950) | 322.08 (480.024) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0812 (20.062) |

| 38 (950) | 347.026 (516.085) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0875 (22.023) |

| 38 (950) | 371.063 (553.011) | .0.0.0 | 38.00 (965) | .0.0.0 | 0.0938 (23.083) |

| 38 (950) | 395.053 (588.057) | .0.0.0 | 38.00 (965) | .0.0.0 | 1.00 (25.04) |

| 38 (950) | 419.035 (623.09) | .0.0.0 | 38.00 (965) | .0.0.0 | 1.0062 (26.097) |

| 38 (950) | 443.047 (660.001) | .0.0.0 | 38.00 (965) | .0.0.0 | 1.0125 (28.058) |

| 38 (950) | 467.05 (695.077) | .0.0.0 | 38.00 (965) | .0.0.0 | 1.0188 (30.018) |

| 38 (950) | 491.007 (730.074) | .0.0.0 | 38.00 (965) | .0.0.0 | 1.025 (31.075) |

Pressure Ratings Of Duplex 2205/ UNS 32205/ UNS 31803 Pipe & Tube

| Schedule of Pipe | Size of Seamless Pipe (inches) | (°F) Temperature | ||||||||

| 200 | 100 | 300 | 500 | 400 | 600 | 700 | 650 | 750 | ||

| 80 | 1" | 3634 | 4213 | 3265 | 2791 | 3002 | 2659 | 2528 | 2580 | 2501 |

| 40 | 1" | 2629 | 3048 | 2362 | 2019 | 2171 | 1924 | 1824 | 1867 | 1810 |

| 40 | 1.5" | 1947 | 2257 | 1750 | 1496 | 1608 | 1425 | 1354 | 1383 | 1340 |

| 160 | 1" | 5296 | 6140 | 4759 | 4068 | 4375 | 3876 | 3684 | 3761 | 3646 |

| 160 | 1.5" | 3984 | 4619 | 3580 | 3060 | 3291 | 2916 | 2772 | 2829 | 2743 |

| 80 | 1.5" | 2744 | 3182 | 2466 | 2108 | 2267 | 2009 | 1909 | 1949 | 1889 |

| 80 | 2" | 2369 | 2747 | 2129 | 1820 | 1957 | 1734 | 1648 | 1682 | 1631 |

| 40 | 2" | 1640 | 1902 | 1474 | 1260 | 1355 | 1201 | 1141 | 1165 | 1129 |

| 40 | 3" | 1558 | 1806 | 1400 | 1196 | 1287 | 1140 | 1084 | 1106 | 1072 |

| 160 | 2" | 3880 | 4499 | 3486 | 2980 | 3205 | 2840 | 2699 | 2755 | 2671 |

| 160 | 3" | 3312 | 3840 | 2976 | 2544 | 2736 | 2424 | 2304 | 2352 | 2280 |

| 80 | 3" | 2202 | 2553 | 1979 | 1691 | 1819 | 1612 | 1532 | 1564 | 1516 |

| 80 | 4" | 1909 | 2213 | 1715 | 1466 | 1577 | 1397 | 1328 | 1355 | 1314 |

| 40 | 4" | 1321 | 1531 | 1187 | 1014 | 1091 | 967 | 919 | 938 | 909 |

| 40 | 5" | 1158 | 1342 | 1040 | 889 | 956 | 847 | 805 | 822 | 797 |

| 160 | 4" | 3106 | 3601 | 2791 | 2386 | 2566 | 2273 | 2161 | 2206 | 2138 |

| 80 | 5" | 1709 | 1981 | 1535 | 1312 | 1411 | 1250 | 1189 | 1213 | 1176 |

| 160 | 5" | 2945 | 3414 | 2646 | 2262 | 2433 | 2155 | 2049 | 2091 | 2027 |

| 80 | 6" | 1650 | 1913 | 1483 | 1267 | 1363 | 1208 | 1148 | 1172 | 1136 |

| 40 | 6" | 1052 | 1219 | 945 | 808 | 869 | 770 | 732 | 747 | 724 |

| 40 | 8" | 926 | 1073 | 832 | 711 | 765 | 678 | 644 | 657 | 637 |

| 160 | 6" | 2836 | 3289 | 2549 | 2179 | 2343 | 2076 | 1973 | 2014 | 1953 |

| 160 | 8" | 2738 | 3175 | 2460 | 2103 | 2262 | 2004 | 1905 | 1944 | 1885 |

| 80 | 8" | 1459 | 1692 | 1311 | 1121 | 1205 | 1068 | 1015 | 1036 | 1005 |

| 80 | 10" | 1388 | 1609 | 1247 | 1066 | 1147 | 1016 | 966 | 986 | 956 |

| 40 | 10" | 840 | 974 | 755 | 945 | 694 | 615 | 584 | 596 | 578 |

| 160 | 10" | 2714 | 3147 | 2439 | 2085 | 2242 | 1986 | 1880 | 1927 | 1868 |

industrial use fitting for Duplex 2205/ UNS 32205/ UNS 31803 Pipe & Tube

Price Of Duplex 2205/ UNS 32205/ UNS 31803 Pipe & Tube

| Duplex and Super Duplex Seamless Pipe | USD $10.21 - $35.51 / kg (FOB Price) on request |

| Duplex and Super Duplex Welded Pipe | USD $10.21 - $35.51 / kg (FOB Price) on request |

| Duplex and Super Duplex Hollow Pipe | USD $10.21 - $35.51 / kg (FOB Price) on request |

| Duplex and Super Duplex Tube | USD $10.21 - $35.51 / kg (FOB Price) on request |

| Duplex and Super Duplex ERW Pipe | USD $10.21 - $35.51 / kg (FOB Price) on request |

Application Of Duplex 2205/ UNS 32205/ UNS 31803 Pipe & Tube

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Duplex 2205/ UNS 32205/ UNS 31803 Pipe & Tube

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

Packing Of Duplex 2205/ UNS 32205/ UNS 31803 Pipe & Tube

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates