Stainless Steel 310/310S Instrumentation Tube Fittings

310 SS Male Tee, ASTM A182 SS 310 Street Elbow, 310 SS Hex Reducing Nipple, DIN 1.4845 Gauge Adaptor, SS 310S Reducing Bushing, UNS S31008 Male Hose Connector, UNS S31000 Hex Long Nipple, Stainless Steel 310S Reducing Street Elbow.

About Stainless Steel 310/310S Instrumentation Tube Fittings

Stainless steel 310/310S instrumentation tube fittings are a type of fitting used to connect and control the flow of fluid in various industries. These fittings are made from a combination of alloy steel and chromium, which gives them their corrosion-resistant properties and high strength. The 310 grade of stainless steel is an austenitic alloy that is composed of about 25% chromium and 20% nickel. This alloy is known for its excellent resistance to oxidation and corrosion at high temperatures, making it ideal for use in high-temperature applications such as furnace and heat exchanger parts. It also has good resistance to carburization and has good creep strength.

The 310S grade of stainless steel is a low-carbon version of the 310 alloy. It is also an austenitic alloy that is composed of about 25% chromium and 20% nickel. The low carbon content of this grade makes it more resistant to intergranular corrosion, which can occur in high-temperature applications. This grade also has good resistance to carburization and has good creep strength.

Both the 310 and 310S grades of stainless steel instrumentation tube fittings have excellent resistance to corrosion and high strength, making them ideal for use in a variety of applications. They also have a relatively low coefficient of thermal expansion, which means they can maintain their shape and size at high temperatures. Additionally, both grades of stainless steel have excellent formability and weldability, making them easy to work with and install. In summary, Stainless steel 310/310S instrumentation tube fittings are known for their corrosion resistance and high strength properties. The 310 grade is an austenitic alloy that is composed of about 25% chromium and 20% nickel, and is known for its excellent resistance to oxidation and corrosion at high temperatures. The 310S grade is a low-carbon version of the 310 alloy, it is more resistant to intergranular corrosion, which can occur in high-temperature applications. Both grades are ideal for high-temperature applications and have excellent formability and weldability.

Our company packs Stainless Steel 310/310S Instrumentation Tube Fittings using high-quality materials to ensure that the fittings are protected during transportation. The fittings are carefully wrapped and packaged to prevent any damage or scratches during transit. They are then placed in sturdy boxes or crates for safe shipment to our customers. Our company takes great care to ensure that the fittings are delivered in perfect condition.

SS 310S Hex Head Plug Exporter, 310 SS Pipe Plug Stockist, ASTM A182 SS 310 Male Connector Manufacturer, SS 310S Reducing Bushing Stockist, DIN 1.4845 Tube To Hose Connector Supplier, ASME SA182 SS 310 Female Cross Exporter.

Specification of Stainless Steel 310/310S Instrumentation Tube Fittings

| Size: | SEA mless:from 1/8" to 2" Welded:from 24" to 96"( or as customer requirements) |

| Pressure Rating: | 3000psi -10000psi |

| OEM Accepted | yes |

| Production Capacity: | 2000 pcs per week |

| Material | Stainless steel(ASTM A403 WP304, 304L, 316, 316L, 321. 1Cr18Ni9Ti, 00Cr19Ni10,00Cr17Ni14Mo2, etc) Alloy steel(ASTM A234 WP12, WP11, WP22, WP5, WP9, WP91, 16MnR, Cr5Mo, 12Cr1MoV, 10CrMo910, 15CrMo, 12Cr2Mo1, etc) |

| Application | Petroleum, chemical, machinery, electric power, shipbuilding, construction, etc. |

| Packing Details: |

|

Ready stock of available for Stainless Steel 310/310S Instrumentation Tube Fittings

Equivalent Grades of Stainless Steel 310/310S Instrumentation Tube Fittings

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 310 | 1.4841 / 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | - | X15CrNi25-20 |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | - | X8CrNi25-21 |

Chemical Composition of Stainless Steel 310/310S Instrumentation Tube Fittings

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 310 | 0.015 max | 2.0 max | 0.15 max | 0.020 max | 0.015 max | 24.00 - 26.00 | 0.10 max | 19.00 - 21.00 | 54.7 min |

| SS 310S | 0.08 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 - 26.00 | 0.75 max | 19.00 - 21.00 | 53.095 min |

Mechanical Properties of Stainless Steel 310/310S Instrumentation Tube Fittings

| Grades | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 310/ 310S | 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

Other Types of Stainless Steel 310/310S Instrumentation Tube Fittings

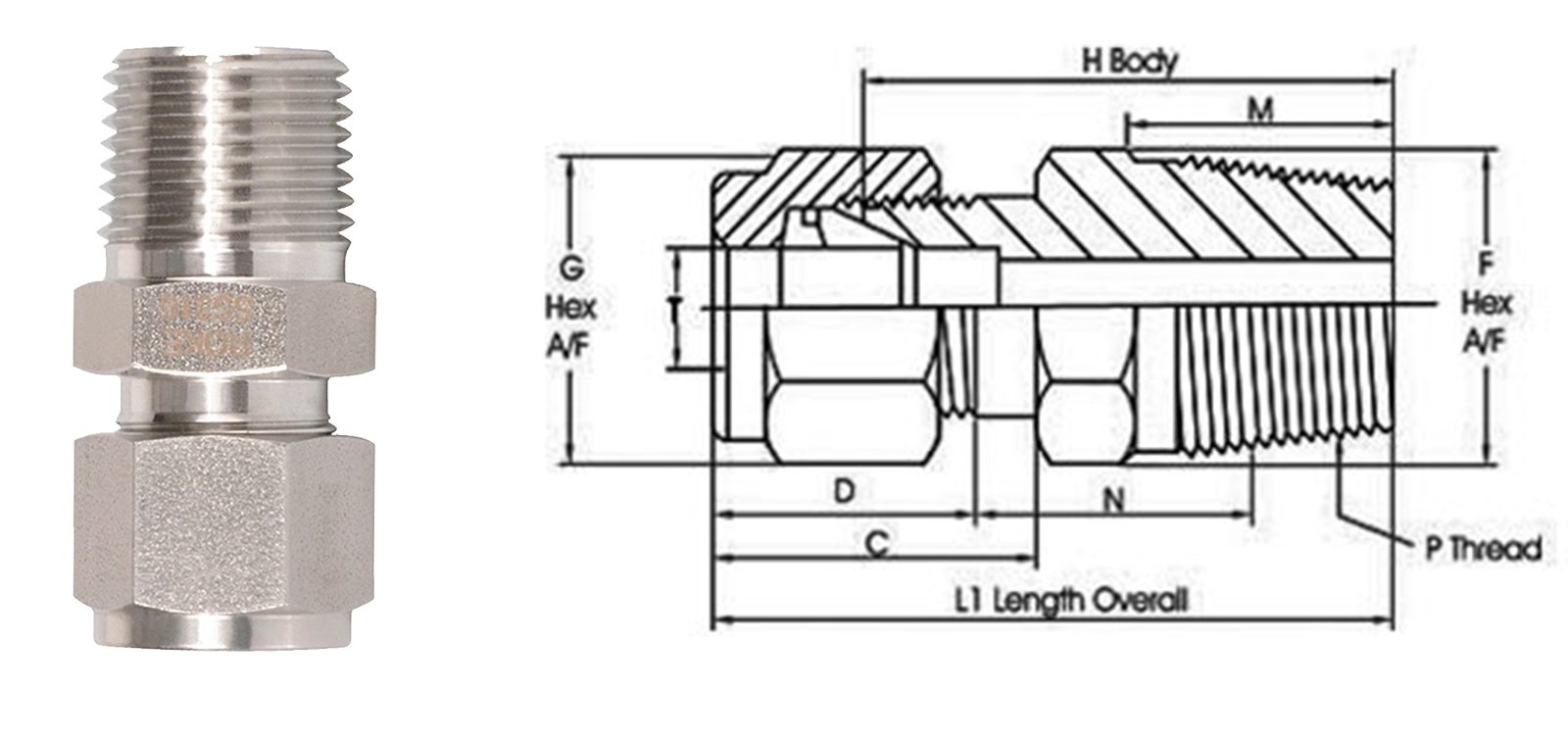

Dimensions Standard Of Stainless Steel 310/310S Instrumentation Tube Fittings

| METRIC RANGE | Dimension in mm | |||||||||

| Part | T | P | L1 | M | C | D | F | G | H | N |

| N0 | mmo/d | Length | Body | Nut | Body | |||||

| 4mMC2 | 4 | 1/8′ | 31.35 | 9.53 | 16.67 | 14.29 | 12 | 12 | 24.21 | 10.72 |

| 4mMC4 | 4 | 1/4′ | 35.72 | 14.29 | 16.67 | 14.29 | 14 | 12 | 29.37 | 15.88 |

| 6mMC2 | 6 | 1/8′ | 33.34 | 9.53 | 18.26 | 15.88 | 14 | 14 | 25.40 | 11.11 |

| 6mMC4 | 6 | 1/4′ | 33.34 | 14.29 | 18.26 | 15.88 | 14 | 14 | 30.16 | 12.70 |

| 6mMC6 | 6 | 3/8′ | 38.89 | 14.29 | 18.26 | 15.88 | 19 | 14 | 30.96 | 13.49 |

| 6mMG8 | 6 | 1/2′ | 44.45 | 19.05 | 18.26 | 15.88 | 22 | 14 | 36.51 | 15.88 |

| 8mMC2 | 8 | 1/8′ | 34.53 | 9.53 | 19.05 | 16.67 | 14 | 17 | 26.59 | 11.51 |

| 8mM04 | 8 | 1/4′ | 39.29 | 14.29 | 19.05 | 16.67 | 14 | 17 | 31.35 | 13.10 |

| 10mM02 | 10 | 1/8′ | 35.72 | 9.53 | 19.84 | 17.46 | 17 | 19 | 27.78 | 11.91 |

| 10mMC4 | 10 | 1/4′ | 40.48 | 14.29 | 19.84 | 17.46 | 17 | 19 | 32.54 | 13.49 |

| 10mMC6 | 10 | 3/8′ | 40.48 | 14.29 | 19.84 | 17.46 | 19 | 19 | 32.54 | 13.49 |

| 10mMC8 | 10 | 1/2′ | 46.04 | 19.05 | 19.84 | 17.46 | 22 | 19 | 38.10 | 15.88 |

| 10mMC12 | 10 | 3/4′ | 46.83 | 19.05 | 19.84 | 17.46 | 27 | 19 | 38.89 | 15.08 |

| 12mMC4 | 12 | 1/4′ | 43.66 | 14.29 | 22.23 | 23.02 | 22 | 22 | 33.34 | 11.11 |

| 12mMC6 | 12 | 3/8′ | 43.66 | 14.29 | 22.23 | 23.02 | 22 | 22 | 33.34 | 11.11 |

| 12mMC8 | 12 | 1/2′ | 48.42 | 19.05 | 22.23 | 23.02 | 22 | 22 | 38.10 | 12.70 |

| 12mM012 | 12 | 3/4′ | 49.21 | 19.05 | 22.23 | 23.02 | 27 | 22 | 38.89 | 11.91 |

| 16mMC6 | 16 | 3/8′ | 44.45 | 14.29 | 22.23 | 24.61 | 24 | 27 | 34.13 | 10.32 |

| 16mMC8 | 16 | 1/2′ | 49.21 | 19.05 | 22.23 | 24.61 | 24 | 27 | 38.89 | 11.91 |

| 16mMC12 | 16 | 3/4′ | 49.21 | 19.05 | 22.23 | 24.61 | 27 | 27 | 38.89 | 10.32 |

| 18mMC8 | 18 | 1/2′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 13.49 |

| 18mMC12 | 18 | 3/4′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 10.32 |

| 18mMC16 | 18 | 1" | 56.36 | 23.81 | 22.23 | 24.61 | 36 | 30 | 46.40 | 14.29 |

| 20mMC8 | 20 | 1/2′ | 50.80 | 19.05 | 22.23 | 24.60 | 27 | 30 | 40.48 | 13.49 |

| 20mM012 | 20 | 3/4′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 10.32 |

| 20mM016 | 20 | 1" | 56.36 | 23.81 | 22.23 | 14.61 | 36 | 30 | 46.04 | 14.39 |

| 25mMC12 | 25 | 3/4′ | 57.15 | 19.05 | 26.19 | 30.96 | 36 | 41 | 45.24 | 11.91 |

| 25mMC16 | 25 | 1" | 61.91 | 23.81 | 26.19 | 30.96 | 36 | 41 | 50.01 | 13.49 |

| METRIC RANGE | Dimention in Inches | |||||||||

| Part | T | P | L1 | M | C | D | F | G | H | N |

| N0 | mmo/d | Length | Body | Nut | Body | |||||

| 1MC1 | 1/16 | 1/16 | .94 | .38 | .44 | .34 | 5/16 | 5/16 | .78 | .34 |

| 1MC2 | 1/16 | 1/8 | 1.00 | .38 | .44 | .34 | 1/2 | 5/16 | .84 | .41 |

| 2MC1 | 1/8 | 1/16 | 1.19 | .38 | .63 | .53 | 1/2 | 7/16 | .91 | .41 |

| 2MC2 | 1/8 | 1/8 | 1.19 | .38 | .63 | .53 | 1/2 | 7/16 | .91 | .41 |

| 2MC4 | 1/8 | 1/4 | 1.41 | .56 | .63 | .53 | 9/16 | 7/16 | 1.13 | .50 |

| 3MC2 | 3/16 | 1/8 | 1.21 | .38 | .63 | .54 | 7/16 | 1/2 | .95 | .43 |

| 3MC4 | 3/16 | 1/4 | 1.42 | .38 | .63 | .54 | 9.16 | 1/2 | 1.16 | .54 |

| 4MC1 | 1/4 | 1/16 | 1.29 | .56 | .70 | .60 | 1/2 | 9/16 | 1.00 | .46 |

| 4MC2 | 1/4 | 1/8 | 1.29 | .56 | .70 | .60 | 1/2 | 9/16 | 1.00 | .45 |

| 4MC4 | 1/4 | 1/4 | 1.50 | .75 | .72 | .63 | 9/16 | 9/16 | 1.19 | .50 |

| 4MC6 | 1/4 | 3/8 | 1.51 | .38 | .70 | .60 | 11/16 | 9/16 | 1.19 | .56 |

| 4MC8 | 1/4 | 1/2 | 1.73 | .56 | .70 | .60 | 7/8 | 9/16 | 1.44 | .67 |

| 5MC2 | 5/16 | 1/8 | 1.34 | .38 | .73 | .64 | 9/16 | 5/8 | 1.05 | .46 |

| 5MC4 | 5/16 | 1/4 | 1.52 | .56 | .73 | .64 | 9/16 | 5/8 | 1.23 | .54 |

| 6MC2 | 3/8 | 1/8 | 1.38 | .56 | .76 | .66 | 5/8 | 11/16 | 1.09 | .48 |

| 6MC4 | 3/8 | 1/4 | 1.57 | .75 | .76 | .66 | 5/8 | 11/16 | 1.28 | .57 |

| 6MC6 | 3/B | 3/8 | 1.57 | .75 | .76 | .66 | 11/16 | 11/16 | 1.28 | .56 |

| 6MC8 | 3/B | 1/2 | 1.79 | .56 | .76 | .66 | 7/8 | 11/16 | 1.50 | .67 |

| 6MC12 | 3/8 | 3/4 | 1.82 | .56 | .76 | .66 | 1-1/16 | 11/16 | 1.53 | .68 |

| 8MC4 | 1/2 | 1/4 | 1.17 | .75 | .86 | .90 | 13/16 | 7/8 | 1.31 | .47 |

| 8MC6 | 1/2 | 3/8 | 1.71 | .75 | .86 | .90 | 13/16 | 7/8 | 1.31 | .46 |

| 8MC8 | 1/2 | 1/2 | 1.90 | .56 | .86 | .90 | 7/8 | 7/8 | 1.50 | .54 |

| 8MC12 | 1/2 | 3/4 | 1.93 | .75 | .86 | .90 | 1-1/16 | 7/8 | 1.53 | .55 |

| 10MC6 | 5/8 | 3/8 | 1.74 | .56 | .86 | .96 | 15/16 | 1 | 1.34 | .43 |

| 10MC8 | 5/8 | 1/2 | 1.93 | .75 | .86 | .96 | 15/16 | 1 | 1.53 | .51 |

| 10MC12 | 5/B | 3/4 | 1.93 | .75 | .86 | .96 | 1-1/16 | 1 | 1.53 | .49 |

| 12MC8 | 3/4 | 1/2 | 1.99 | .75 | .86 | .96 | 1-1/16 | 1-1/8 | 1.59 | .57 |

| 12MC12 | 3/4 | 3/4 | 1.99 | .75 | .86 | .96 | 1-1/16 | 1-1/18 | 1.59 | .55 |

| 12MC16 | 3/4 | 1 | 2.21 | .94 | .86 | .96 | 1-3/16 | 1-1/8 | 1.81 | .68 |

| 16MC12 | 1 | 3/4 | 2.26 | .75 | 1.04 | 1.23 | 1-3/8 | 1-1/2 | 1.78 | .55 |

| 16MC16 | 1 | 1 | 2.45 | .94 | 1.04 | 1.23 | 1-3/8 | 1-1/2 | 1.97 | .65 |

industrial use fitting for Stainless Steel 310/310S Instrumentation Tube Fittings

Price Of Stainless Steel 310/310S Instrumentation Tube Fittings

| Stainless Steel Male Connector | USD $2.0 - $10.09 / Piece (FOB Price) on request |

| Stainless Steel Hex Nipple | USD $2.0 - $10.09 / Piece (FOB Price) on request |

| Stainless Steel Reducing Coupling | USD $2.0 - $10.09 / Piece (FOB Price) on request |

| Stainless Steel Adaptor | USD $2.0 - $10.09 / Piece (FOB Price) on request |

| Stainless Steel Bushing | USD $2.0 - $10.09 / Piece (FOB Price) on request |

Application Of Stainless Steel 310/310S Instrumentation Tube Fittings

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Stainless Steel 310/310S Instrumentation Tube Fittings

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

Packing Of Stainless Steel 310/310S Instrumentation Tube Fittings

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

Stainless Steel Instrumentation Tube Fittings

- Stainless Steel 304/ 304L/ 304H Instrumentation Tube Fittings

- Stainless Steel 309 Instrumentation Tube Fittings

- Stainless Steel 310/ 310S Instrumentation Tube Fittings

- Stainless Steel 316/ 316L/ 316Ti Instrumentation Tube Fittings

- Stainless Steel 321 Instrumentation Tube Fittings

- Stainless Steel 347/ 347H Instrumentation Tube Fittings

- Stainless Steel 410/420/430 Instrumentation Tube Fittings

- Stainless Steel 446 Instrumentation Tube Fittings

- Stainless Steel 904L Instrumentation Tube Fittings

- Stainless Steel 15-5 PH Instrumentation Tube Fittings

- Stainless Steel 17-4 PH Instrumentation Tube Fittings