Stainless Steel 316/316L/316Ti Instrumentation Tube Fittings

UNS S31603 Pipe Cap, 316L SS Hollow Hex Plug, SS 316 Union Ball Joint, 316L SS Reducing Adaptor, ASME SA182 SS 316Ti Reducing Coupling, 316 SS Hex Reducing Nipple, 316Ti SS Pipe Plug, DIN 1.4404 Gauge Adaptor.

About Stainless Steel 316/316L/316Ti Instrumentation Tube Fittings

Stainless steel 316, 316L, and 316Ti are all variations of the 316 grade of stainless steel. These grades are commonly used in instrumentation tube fittings due to their excellent corrosion resistance and high strength.

Stainless steel 316 is a standard molybdenum-bearing grade, and is the most commonly used grade of stainless steel. It has excellent corrosion resistance in a wide range of chemical and industrial environments. It also has excellent toughness and strength, making it ideal for use in instrumentation tube fittings. Stainless steel 316L is a low carbon version of 316, which is used in applications where welding is required. The lower carbon content of 316L reduces the risk of intergranular corrosion, and also improves the toughness and strength of the material. This grade is particularly suitable for use in instrumentation tube fittings that require high corrosion resistance and strength.

Stainless steel 316Ti is a titanium-stabilized version of 316, which improves its resistance to intergranular corrosion. The addition of titanium also increases the strength and toughness of the material. This grade is particularly suitable for use in instrumentation tube fittings that are exposed to high temperatures and corrosive environments. All three of these grades of stainless steel have excellent resistance to chloride pitting and crevice corrosion, making them ideal for use in marine and coastal environments. They are also resistant to sulfuric acid and other strong acids, making them suitable for use in chemical processing applications. All three of these grades of stainless steel have high temperature strength and good creep resistance, making them suitable for use in high temperature environments. 316Ti grade also has better high temperature properties than 316 and 316L.

Overall, stainless steel 316, 316L, and 316Ti are all excellent choices for instrumentation tube fittings due to their high strength, corrosion resistance, and suitability for use in a wide range of environments. Our company packs stainless steel 316, 316L, and 316Ti instrumentation tube fittings using high-quality, durable packaging materials. This includes using sturdy wooden crates or boxes, with each fitting individually wrapped in a layer of protective plastic to prevent damage during transportation. We also use foam padding to protect the fittings from any impact or shock, and to keep them securely in place. Additionally, we use rust inhibitors and desiccants to protect the fittings from corrosion and moisture during storage and transport. All the package is properly labeled and marked to ensure easy identification and compliance with all relevant regulations. Our packaging process is designed to ensure that the fittings reach our customers in excellent condition, ready for immediate installation and use.

SS 316L Hex Head Plug Exporter, DIN 1.4401 Branch Tee Supplier, UNS S31603 Male Hose Connector Stockist, DIN 1.4404 Gauge Adaptor Manufacturer, UNS S31635 Female Elbow Manufacturer.

Specification of Stainless Steel 316/316L/316Ti Instrumentation Tube Fittings

| Size: | SEA mless:from 1/8" to 2" Welded:from 24" to 96"( or as customer requirements) |

| Pressure Rating: | 3000psi -10000psi |

| OEM Accepted | yes |

| Production Capacity: | 2000 pcs per week |

| Material | Stainless steel(ASTM A403 WP304, 304L, 316, 316L, 321. 1Cr18Ni9Ti, 00Cr19Ni10,00Cr17Ni14Mo2, etc) Alloy steel(ASTM A234 WP12, WP11, WP22, WP5, WP9, WP91, 16MnR, Cr5Mo, 12Cr1MoV, 10CrMo910, 15CrMo, 12Cr2Mo1, etc) |

| Application | Petroleum, chemical, machinery, electric power, shipbuilding, construction, etc. |

| Packing Details: |

|

Ready stock of available for Stainless Steel 316/316L/316Ti Instrumentation Tube Fittings

Equivalent Grades of Stainless Steel 316/316L/316Ti Instrumentation Tube Fittings

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST |

| SS 316 | S31600 | 1.4401 / 1.4436 | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 | SUS 316 | 316S31 / 316S33 | - |

| SS 316L | S31603 | 1.4404 / 1.4435 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 |

| SS 316Ti | S31635 | 1.4571 | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 | SUS 316Ti | 904S13 | - |

Chemical Composition of Stainless Steel 316/316L/316Ti Instrumentation Tube Fittings

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| 316 | 0.08 max | 2.0 max | 0.75 max | 0.045 max | 0.03 max | 16.0 - 18.0 | 2.0 - 3.0 | 10.0 - 14.0 | 0.10 max |

| 316L | 0.03 max | 2.0 max | 0.75 max | 0.045 max | 0.03 max | 16.0 - 18.0 | 2.0 - 3.0 | 10.0 - 14.0 | 0.10 max |

| 316TI | 0.08 max | 2.0 max | 0.75 max | 0.045 max | 0.03 max | 16.0 - 18.0 | 2.0 - 3.0 | 10.0 - 14.0 | 0.1 min |

Mechanical Properties of Stainless Steel 316/316L/316Ti Instrumentation Tube Fittings

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 316 | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| 316L/ 316TI | 8.0 g/cm3 | 1399 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Other Types of Stainless Steel 316/316L/316Ti Instrumentation Tube Fittings

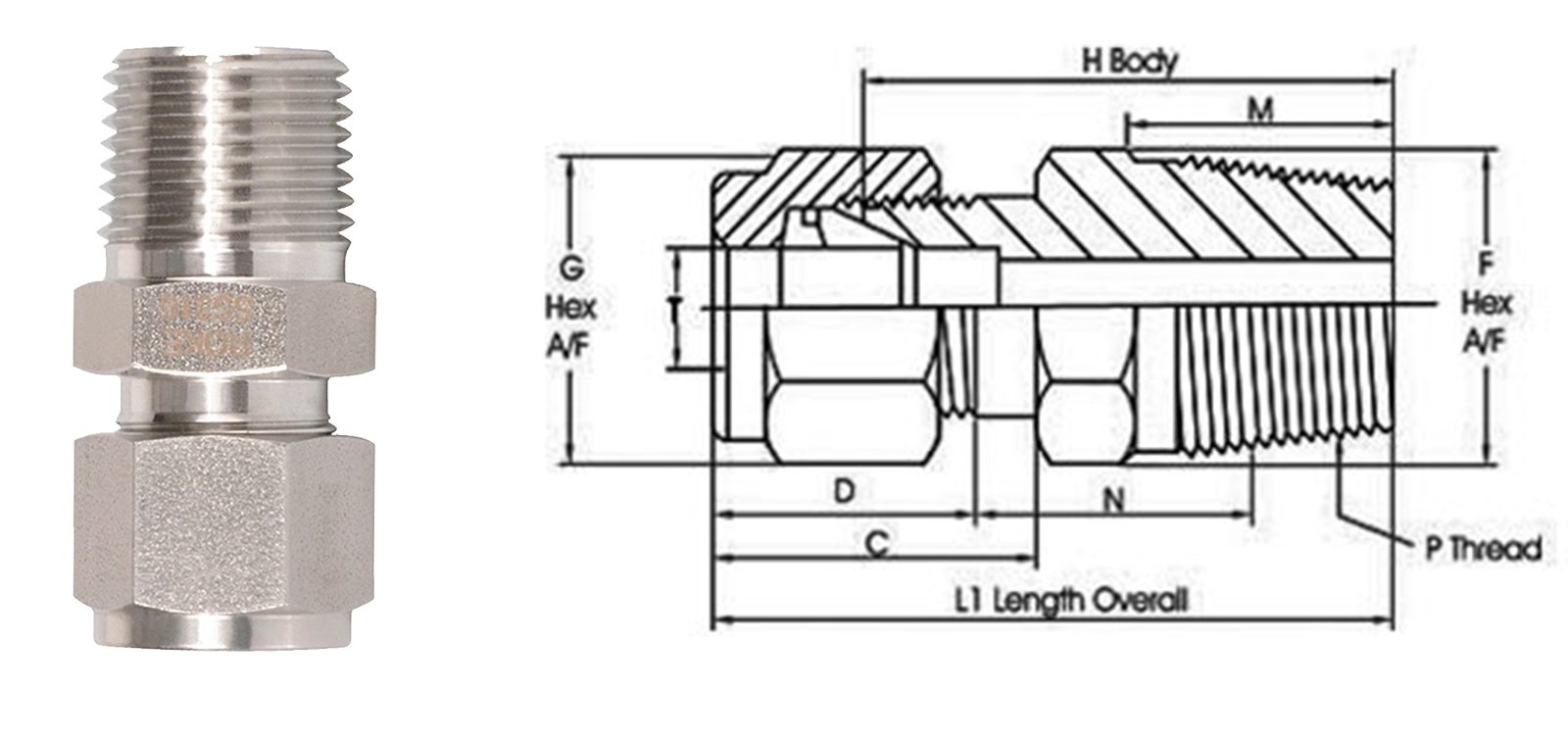

Dimensions Standard Of Stainless Steel 316/316L/316Ti Instrumentation Tube Fittings

| METRIC RANGE | Dimension in mm | |||||||||

| Part | T | P | L1 | M | C | D | F | G | H | N |

| N0 | mmo/d | Length | Body | Nut | Body | |||||

| 4mMC2 | 4 | 1/8′ | 31.35 | 9.53 | 16.67 | 14.29 | 12 | 12 | 24.21 | 10.72 |

| 4mMC4 | 4 | 1/4′ | 35.72 | 14.29 | 16.67 | 14.29 | 14 | 12 | 29.37 | 15.88 |

| 6mMC2 | 6 | 1/8′ | 33.34 | 9.53 | 18.26 | 15.88 | 14 | 14 | 25.40 | 11.11 |

| 6mMC4 | 6 | 1/4′ | 33.34 | 14.29 | 18.26 | 15.88 | 14 | 14 | 30.16 | 12.70 |

| 6mMC6 | 6 | 3/8′ | 38.89 | 14.29 | 18.26 | 15.88 | 19 | 14 | 30.96 | 13.49 |

| 6mMG8 | 6 | 1/2′ | 44.45 | 19.05 | 18.26 | 15.88 | 22 | 14 | 36.51 | 15.88 |

| 8mMC2 | 8 | 1/8′ | 34.53 | 9.53 | 19.05 | 16.67 | 14 | 17 | 26.59 | 11.51 |

| 8mM04 | 8 | 1/4′ | 39.29 | 14.29 | 19.05 | 16.67 | 14 | 17 | 31.35 | 13.10 |

| 10mM02 | 10 | 1/8′ | 35.72 | 9.53 | 19.84 | 17.46 | 17 | 19 | 27.78 | 11.91 |

| 10mMC4 | 10 | 1/4′ | 40.48 | 14.29 | 19.84 | 17.46 | 17 | 19 | 32.54 | 13.49 |

| 10mMC6 | 10 | 3/8′ | 40.48 | 14.29 | 19.84 | 17.46 | 19 | 19 | 32.54 | 13.49 |

| 10mMC8 | 10 | 1/2′ | 46.04 | 19.05 | 19.84 | 17.46 | 22 | 19 | 38.10 | 15.88 |

| 10mMC12 | 10 | 3/4′ | 46.83 | 19.05 | 19.84 | 17.46 | 27 | 19 | 38.89 | 15.08 |

| 12mMC4 | 12 | 1/4′ | 43.66 | 14.29 | 22.23 | 23.02 | 22 | 22 | 33.34 | 11.11 |

| 12mMC6 | 12 | 3/8′ | 43.66 | 14.29 | 22.23 | 23.02 | 22 | 22 | 33.34 | 11.11 |

| 12mMC8 | 12 | 1/2′ | 48.42 | 19.05 | 22.23 | 23.02 | 22 | 22 | 38.10 | 12.70 |

| 12mM012 | 12 | 3/4′ | 49.21 | 19.05 | 22.23 | 23.02 | 27 | 22 | 38.89 | 11.91 |

| 16mMC6 | 16 | 3/8′ | 44.45 | 14.29 | 22.23 | 24.61 | 24 | 27 | 34.13 | 10.32 |

| 16mMC8 | 16 | 1/2′ | 49.21 | 19.05 | 22.23 | 24.61 | 24 | 27 | 38.89 | 11.91 |

| 16mMC12 | 16 | 3/4′ | 49.21 | 19.05 | 22.23 | 24.61 | 27 | 27 | 38.89 | 10.32 |

| 18mMC8 | 18 | 1/2′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 13.49 |

| 18mMC12 | 18 | 3/4′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 10.32 |

| 18mMC16 | 18 | 1" | 56.36 | 23.81 | 22.23 | 24.61 | 36 | 30 | 46.40 | 14.29 |

| 20mMC8 | 20 | 1/2′ | 50.80 | 19.05 | 22.23 | 24.60 | 27 | 30 | 40.48 | 13.49 |

| 20mM012 | 20 | 3/4′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 10.32 |

| 20mM016 | 20 | 1" | 56.36 | 23.81 | 22.23 | 14.61 | 36 | 30 | 46.04 | 14.39 |

| 25mMC12 | 25 | 3/4′ | 57.15 | 19.05 | 26.19 | 30.96 | 36 | 41 | 45.24 | 11.91 |

| 25mMC16 | 25 | 1" | 61.91 | 23.81 | 26.19 | 30.96 | 36 | 41 | 50.01 | 13.49 |

| METRIC RANGE | Dimention in Inches | |||||||||

| Part | T | P | L1 | M | C | D | F | G | H | N |

| N0 | mmo/d | Length | Body | Nut | Body | |||||

| 1MC1 | 1/16 | 1/16 | .94 | .38 | .44 | .34 | 5/16 | 5/16 | .78 | .34 |

| 1MC2 | 1/16 | 1/8 | 1.00 | .38 | .44 | .34 | 1/2 | 5/16 | .84 | .41 |

| 2MC1 | 1/8 | 1/16 | 1.19 | .38 | .63 | .53 | 1/2 | 7/16 | .91 | .41 |

| 2MC2 | 1/8 | 1/8 | 1.19 | .38 | .63 | .53 | 1/2 | 7/16 | .91 | .41 |

| 2MC4 | 1/8 | 1/4 | 1.41 | .56 | .63 | .53 | 9/16 | 7/16 | 1.13 | .50 |

| 3MC2 | 3/16 | 1/8 | 1.21 | .38 | .63 | .54 | 7/16 | 1/2 | .95 | .43 |

| 3MC4 | 3/16 | 1/4 | 1.42 | .38 | .63 | .54 | 9.16 | 1/2 | 1.16 | .54 |

| 4MC1 | 1/4 | 1/16 | 1.29 | .56 | .70 | .60 | 1/2 | 9/16 | 1.00 | .46 |

| 4MC2 | 1/4 | 1/8 | 1.29 | .56 | .70 | .60 | 1/2 | 9/16 | 1.00 | .45 |

| 4MC4 | 1/4 | 1/4 | 1.50 | .75 | .72 | .63 | 9/16 | 9/16 | 1.19 | .50 |

| 4MC6 | 1/4 | 3/8 | 1.51 | .38 | .70 | .60 | 11/16 | 9/16 | 1.19 | .56 |

| 4MC8 | 1/4 | 1/2 | 1.73 | .56 | .70 | .60 | 7/8 | 9/16 | 1.44 | .67 |

| 5MC2 | 5/16 | 1/8 | 1.34 | .38 | .73 | .64 | 9/16 | 5/8 | 1.05 | .46 |

| 5MC4 | 5/16 | 1/4 | 1.52 | .56 | .73 | .64 | 9/16 | 5/8 | 1.23 | .54 |

| 6MC2 | 3/8 | 1/8 | 1.38 | .56 | .76 | .66 | 5/8 | 11/16 | 1.09 | .48 |

| 6MC4 | 3/8 | 1/4 | 1.57 | .75 | .76 | .66 | 5/8 | 11/16 | 1.28 | .57 |

| 6MC6 | 3/B | 3/8 | 1.57 | .75 | .76 | .66 | 11/16 | 11/16 | 1.28 | .56 |

| 6MC8 | 3/B | 1/2 | 1.79 | .56 | .76 | .66 | 7/8 | 11/16 | 1.50 | .67 |

| 6MC12 | 3/8 | 3/4 | 1.82 | .56 | .76 | .66 | 1-1/16 | 11/16 | 1.53 | .68 |

| 8MC4 | 1/2 | 1/4 | 1.17 | .75 | .86 | .90 | 13/16 | 7/8 | 1.31 | .47 |

| 8MC6 | 1/2 | 3/8 | 1.71 | .75 | .86 | .90 | 13/16 | 7/8 | 1.31 | .46 |

| 8MC8 | 1/2 | 1/2 | 1.90 | .56 | .86 | .90 | 7/8 | 7/8 | 1.50 | .54 |

| 8MC12 | 1/2 | 3/4 | 1.93 | .75 | .86 | .90 | 1-1/16 | 7/8 | 1.53 | .55 |

| 10MC6 | 5/8 | 3/8 | 1.74 | .56 | .86 | .96 | 15/16 | 1 | 1.34 | .43 |

| 10MC8 | 5/8 | 1/2 | 1.93 | .75 | .86 | .96 | 15/16 | 1 | 1.53 | .51 |

| 10MC12 | 5/B | 3/4 | 1.93 | .75 | .86 | .96 | 1-1/16 | 1 | 1.53 | .49 |

| 12MC8 | 3/4 | 1/2 | 1.99 | .75 | .86 | .96 | 1-1/16 | 1-1/8 | 1.59 | .57 |

| 12MC12 | 3/4 | 3/4 | 1.99 | .75 | .86 | .96 | 1-1/16 | 1-1/18 | 1.59 | .55 |

| 12MC16 | 3/4 | 1 | 2.21 | .94 | .86 | .96 | 1-3/16 | 1-1/8 | 1.81 | .68 |

| 16MC12 | 1 | 3/4 | 2.26 | .75 | 1.04 | 1.23 | 1-3/8 | 1-1/2 | 1.78 | .55 |

| 16MC16 | 1 | 1 | 2.45 | .94 | 1.04 | 1.23 | 1-3/8 | 1-1/2 | 1.97 | .65 |

industrial use fitting for Stainless Steel 316/316L/316Ti Instrumentation Tube Fittings

Price Of Stainless Steel 316/316L/316Ti Instrumentation Tube Fittings

| Stainless Steel Male Connector | USD $2.0 - $10.09 / Piece (FOB Price) on request |

| Stainless Steel Hex Nipple | USD $2.0 - $10.09 / Piece (FOB Price) on request |

| Stainless Steel Reducing Coupling | USD $2.0 - $10.09 / Piece (FOB Price) on request |

| Stainless Steel Adaptor | USD $2.0 - $10.09 / Piece (FOB Price) on request |

| Stainless Steel Bushing | USD $2.0 - $10.09 / Piece (FOB Price) on request |

Application Of Stainless Steel 316/316L/316Ti Instrumentation Tube Fittings

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Stainless Steel 316/316L/316Ti Instrumentation Tube Fittings

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

Packing Of Stainless Steel 316/316L/316Ti Instrumentation Tube Fittings

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

Stainless Steel Instrumentation Tube Fittings

- Stainless Steel 304/ 304L/ 304H Instrumentation Tube Fittings

- Stainless Steel 309 Instrumentation Tube Fittings

- Stainless Steel 310/ 310S Instrumentation Tube Fittings

- Stainless Steel 316/ 316L/ 316Ti Instrumentation Tube Fittings

- Stainless Steel 321 Instrumentation Tube Fittings

- Stainless Steel 347/ 347H Instrumentation Tube Fittings

- Stainless Steel 410/420/430 Instrumentation Tube Fittings

- Stainless Steel 446 Instrumentation Tube Fittings

- Stainless Steel 904L Instrumentation Tube Fittings

- Stainless Steel 15-5 PH Instrumentation Tube Fittings

- Stainless Steel 17-4 PH Instrumentation Tube Fittings