Stainless Steel 321 Fasteners

ASTM A193 SS 321 Grub screw, SS 321 Roofing screws, DIN 1.4541 Star washer, SS 321 Lock washer, ASME SA193 SS 321 Sealing washer, UNS S32100 Captive-nuts, DIN 1.4541 Self-tapping-screw.

About Stainless Steel 321 Fasteners

Nissan Steel is a renowned manufacturing company in Mumbai, India, that manufactures, sells, and exports high-quality Stainless Steel 321 Fasteners. These Stainless Steel 321H fasteners are manufactured using cutting-edge technology and excellent raw materials. Stainless Steel 321 Fasteners are austenitic stainless steel treated with titanium, making it more corrosion-resistant. After being heated to between 800 and 1500 degrees Fahrenheit (427 and 816 degrees Celsius), chromium carbide transforms into a solid highly resistant to corrosion between grains.

SS 321H Fasteners comprise an alloy containing between 0.04% and 0.10% carbon. The alloy is oxidation-resistant at temperatures up to 1500 degrees Fahrenheit (816 degrees Celsius) and has superior ruptured creep and stress properties than alloys 304 and 304L. This also has good low-temperature tolerance. It was designed to resist bending and be more durable at temperatures above 1000 degrees Fahrenheit (537 degrees C). SS 321 fasteners can only be hardened while in the cold. Using typical welding procedures, it is simple to weld and manipulate in production. Most diluted organic acids can be utilised with SS 321 Fasteners at mild temperatures. Pure phosphoric acid and up to 10% diluted solutions can be employed at low and high temperatures. Alloy 321 is resistant to polythionic acid-induced stress corrosion cracking in hydrocarbon service. They work in moderately hot caustic solutions without chloride or fluoride. 321 SS Fasteners, even in modest concentrations, don’t operate well in chloride or sulphuric acid solutions.

Stainless Steel 1.4541, 1.4878 Fasteners can be utilised for various applications, including aircraft piston engine manifolds and exhaust stacks, expansion joints, thermal oxidisers, refining equipment, high-temperature chemical processes equipment, food production and storage equipment, etc. Our Stainless Steel 321H Fasteners are available in various sizes, specifications, widths, grade materials, and dimensions and can be customised to meet the needs of each client.

UNS S32100 Self drilling screws Stockist, SS 321 Lock washer Exporter, DIN 1.4541 Sleeve nuts Supplier, UNS S32100 Captive-nuts Stockist.

Specification of Stainless Steel 321 Fasteners

| Specifications | ASTM A 193 / ASME SA 193 |

| Standard | DIN, ISO ,JIS ,GB, IS, BS, ASTM and all International Standards |

| Size | M3 - M100 | 3/6″ - 4″ | Custom Sizes |

| Fasteners Length | 3 mm - 200 mm | Custom Sizes |

| Nuts Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Washers Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads available | UNF, BSW, BSF, METRIC, UNC, or as required |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Head | Hex, Square, Round, Hex flange, Flat, T-head & Triangular etc. |

| Neck type | Hex, Square, Triangular, Oval & Knurled etc. |

| Surface Coating | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Manufacturing Process | Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing. |

Ready stock of available for Stainless Steel 321 Fasteners

Equivalent Grades of Stainless Steel 321 Fasteners

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 321 | 1.4541 | S32100 | SUS 321 | X6CrNiTi18-10 |

Chemical Composition of Stainless Steel 321 Fasteners

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti |

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 0.10 max | 9.00 - 12.00 | 5(C+N) – 0.70 max |

Mechanical Properties of Stainless Steel 321 Fasteners

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1457 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Other Types of Stainless Steel 321 Fasteners

Dimensions Standard Of Stainless Steel 321 Fasteners

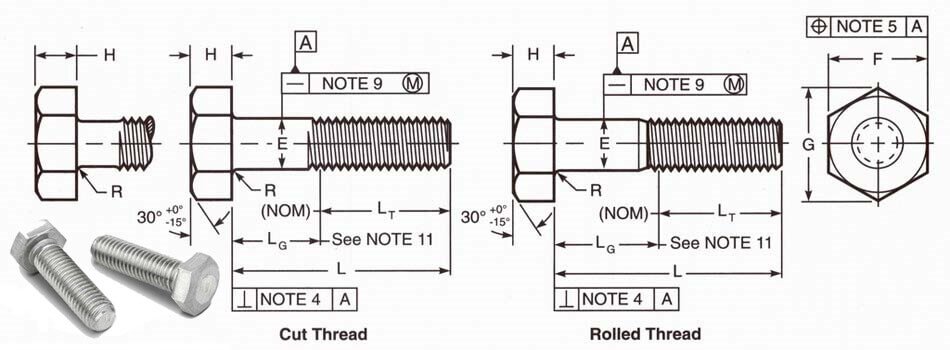

Dimensions Chart of Bolts

| Nominal Size or Basic Product Diameter | Full-Size Body Diameter, E | Width Across Flats, F | Width Across Corners, G | Head Height, H Basic | Radius of Fillet, R | Nominal Thread Length for Bolt Lengths, LT |

|||||||||

| inch | mm | Max | Min | Basic inch | Max | Min | Max | Min | Basic inch | Max | Min | Max | Min | 6 in. and Shoter | Over 6 in. |

| 1⁄4 | 0.25 | 0.26 | 0.237 | 7⁄16 | 0.438 | 0.425 | 0.505 | 0.484 | 11⁄64 | 0.188 | 0.15 | 0.03 | 0.01 | 0.75 | 1 |

| 5⁄16 | 0.3125 | 0.324 | 0.298 | 1⁄2 | 0.5 | 0.484 | 0.577 | 0.552 | 7⁄32 | 0.235 | 0.195 | 0.03 | 0.01 | 0.875 | 1.125 |

| 3⁄8 | 0.375 | 0.388 | 0.36 | 9⁄16 | 0.562 | 0.544 | 0.65 | 0.62 | 1⁄4 | 0.268 | 0.226 | 0.03 | 0.01 | 1 | 1.25 |

| 7⁄16 | 0.4375 | 0.452 | 0.421 | 5⁄8 | 0.625 | 0.603 | 0.722 | 0.687 | 19⁄64 | 0.316 | 0.272 | 0.03 | 0.01 | 1.125 | 1.375 |

| 1⁄2 | 0.5 | 0.515 | 0.482 | 3⁄4 | 0.75 | 0.725 | 0.866 | 0.826 | 11⁄32 | 0.364 | 0.302 | 0.03 | 0.01 | 1.25 | 1.5 |

| 5⁄8 | 0.625 | 0.642 | 0.605 | 15⁄16 | 0.938 | 0.906 | 1.083 | 1.033 | 27⁄64 | 0.444 | 0.378 | 0.06 | 0.02 | 1.5 | 1.75 |

| 3⁄4 | 0.75 | 0.768 | 0.729 | 11⁄8 | 1.125 | 1.088 | 1.299 | 1.24 | 1⁄2 | 0.524 | 0.455 | 0.06 | 0.02 | 1.75 | 2 |

| 7⁄8 | 0.875 | 0.895 | 0.852 | 1 5⁄16 | 1.312 | 1.269 | 1.516 | 1.447 | 37⁄64 | 0.604 | 0.531 | 0.06 | 0.02 | 2 | 2.25 |

| 1 | 1 | 1.022 | 0.976 | 1 1⁄2 | 1.5 | 1.45 | 1.732 | 1.653 | 43⁄64 | 0.7 | 0.591 | 0.09 | 0.03 | 2.25 | 2.5 |

| 1 1⁄8 | 1.125 | 1.149 | 1.098 | 1 11⁄16 | 1.688 | 1.631 | 1.949 | 1.859 | 3⁄4 | 0.78 | 0.658 | 0.09 | 0.03 | 2.5 | 2.75 |

| 1 1⁄4 | 1.25 | 1.277 | 1.223 | 1 7⁄8 | 1.875 | 1.812 | 2.165 | 2.066 | 27⁄32 | 0.876 | 0.749 | 0.09 | 0.03 | 2.75 | 3 |

| 1 3⁄8 | 1.375 | 1.404 | 1.345 | 2 1⁄16 | 2.062 | 1.994 | 2.382 | 2.273 | 29⁄32 | 0.94 | 0.81 | 0.09 | 0.03 | 3 | 3.25 |

| 1 1⁄2 | 1.5 | 1.531 | 1.47 | 2 1⁄4 | 2.25 | 2.175 | 2.598 | 2.48 | 1 | 1.036 | 0.902 | 0.09 | 0.03 | 3.25 | 3.5 |

| 1 5⁄8 | 1.625 | 1.658 | 1.591 | 2 7⁄16 | 2.438 | 2.356 | 2.815 | 2.616 | 1 3⁄32 | 1.116 | 0.978 | 0.09 | 0.03 | 3.5 | 3.75 |

| 1 3⁄4 | 1.75 | 1.785 | 1.716 | 2 5⁄8 | 2.625 | 2.538 | 3.031 | 2.893 | 1 5⁄32 | 1.196 | 1.054 | 0.12 | 0.04 | 3.75 | 4 |

| 1 7⁄8 | 1.875 | 1.912 | 1.839 | 2 13⁄16 | 2.812 | 2.719 | 3.248 | 3.099 | 1 1⁄4 | 1.276 | 1.13 | 0.12 | 0.04 | 4 | 4.25 |

| 2 | 2 | 2.039 | 1.964 | 3 | 3 | 2.9 | 3.464 | 3.306 | 1 11⁄32 | 1.388 | 1.175 | 0.12 | 0.04 | 4.25 | 4.5 |

| 2 1⁄4 | 2.25 | 2.305 | 2.214 | 3 3⁄8 | 3.375 | 3.262 | 3.897 | 3.719 | 1 1⁄2 | 1.548 | 1.327 | 0.19 | 0.06 | 4.75 | 5 |

| 2 1⁄2 | 2.5 | 2.559 | 2.461 | 3 3⁄4 | 3.75 | 3.625 | 4.33 | 4.133 | 1 21⁄32 | 1.708 | 1.479 | 0.19 | 0.06 | 5.25 | 5.5 |

| 2 3⁄4 | 2.75 | 2.827 | 2.711 | 4 1⁄8 | 4.125 | 3.988 | 4.763 | 4.546 | 1 13⁄16 | 1.869 | 1.632 | 0.19 | 0.06 | 5.75 | 6 |

| 3 | 3 | 3.081 | 2.961 | 4 1⁄2 | 4.5 | 4.35 | 5.196 | 4.959 | 2 | 2.06 | 1.815 | 0.19 | 0.06 | 6.25 | 6.5 |

| 3 1⁄4 | 3.25 | 3.335 | 3.21 | 4 7⁄8 | 4.875 | 4.712 | 5.629 | 5.372 | 2 3⁄16 | 2.251 | 1.936 | 0.19 | 0.06 | 6.75 | 7 |

| 3 1⁄2 | 3.5 | 3.589 | 3.461 | 5 1⁄4 | 5.25 | 5.075 | 6.062 | 5.786 | 2 5⁄16 | 2.38 | 2.057 | 0.19 | 0.06 | 7.25 | 7.5 |

| 3 3⁄4 | 3.75 | 3.858 | 3.726 | 5 5⁄8 | 5.625 | 5.437 | 6.495 | 6.198 | 2 1⁄2 | 2.572 | 2.241 | 0.19 | 0.06 | 7.75 | 8 |

| 4 | 4 | 4.111 | 3.975 | 6 | 6 | 5.8 | 6.928 | 6.612 | 2 11⁄16 | 2.764 | 2.424 | 0.19 | 0.06 | 8.25 | 8.5 |

Dimensions Chart of Stud Bolts

| Nominal Size Diameter, D inch | Tap End Full Thread Length, BM | Umax = 2P | Minimum Nut End Full Thread Length, Bmin |

||||||

| Nominal | Min. | Max. | UNC & NC-5 Thread | UNF Thread | 8UN Thread | L ≤ 10 | 10 < L ≤ 16 | L > 16 | |

| 1/4 | 0.375 | 0.350 | 0.400 | 0.100 | 0.071 | ... | 0.750 | 1.000 | 1.500 |

| 5/16 | 0.469 | 0.440 | 0.498 | 0.111 | 0.083 | -- | 0.875 | 1.125 | 1.625 |

| 3/8 | 0.563 | 0.532 | 0.594 | 0.125 | 0.083 | -- | 1.000 | 1.250 | 1.750 |

| 7/16 | 0.656 | 0.620 | 0.692 | 0.143 | 0.100 | -- | 1.125 | 1.375 | 1.875 |

| 1/2 | 0.750 | 0.708 | 0.792 | 0.154 | 0.100 | -- | 1.250 | 1.500 | 2.000 |

| 9/16 | 0.844 | 0.802 | 0.896 | 0.167 | 0.111 | -- | 1.375 | 1.625 | 2.125 |

| 5/8 | 0.938 | 0.892 | 0.983 | 0.182 | 0.111 | -- | 1.500 | 1.750 | 2.250 |

| 3/4 | 1.1.25 | 1.075 | 1.175 | 0.200 | 0.125 | -- | 1.750 | 2.000 | 2.500 |

| 7/8 | 1.313 | 1.258 | 1.368 | 0.222 | 0.143 | -- | 2.000 | 2.250 | 2.750 |

| 1 | 1.500 | 1.438 | 1.562 | 0.250 | 0.167 | -- | 2.250 | 2.500 | 3.000 |

| 1 1/8 | 1.688 | 1.625 | 1.750 | 0.286 | 0.167 | 0.250 | 2.500 | 2.750 | 3.250 |

| 1 1/4 | 1.875 | 1.813 | 1.938 | 0.286 | 0.167 | 0.250 | 2.750 | 3.000 | 3.500 |

| 1 3/8 | 2.063 | 2.000 | 2.125 | 0.333 | 0.167 | 0.250 | 3.000 | 3.250 | 3.750 |

| 1 1/2 | 2.250 | 2.188 | 2.313 | 0.333 | 0.167 | 0.250 | 3.250 | 3.500 | 4.000 |

| 1 5/8 | 2.438 | 2.375 | 2.500 | -- | -- | 0.250 | 3.500 | 3.750 | 4.250 |

| 1 3/4 | 2.625 | 2.563 | 2.688 | 0.400 | -- | 0.250 | 3.750 | 4.000 | 4.500 |

| 1 7/8 | 2.813 | 2.750 | 2.875 | -- | -- | 0.250 | 4.000 | 4.250 | 4.750 |

| 2 | 3.000 | 2.925 | 3.075 | 0.444 | -- | 0.250 | 4.250 | 4.500 | 5.000 |

| 2 1/4 | 3.375 | 3.300 | 3.450 | 0.444 | -- | 0.250 | 4.750 | 5.000 | 5.500 |

| 2 1/2 | 3.750 | 3.675 | 3.825 | 0.500 | -- | 0.250 | 5.250 | 5.500 | 6.000 |

| 2 3/4 | 4.125 | 4.050 | 4.200 | 0.500 | -- | 0.250 | 5.750 | 6.000 | 6.500 |

| 3 | 4.500 | 4.425 | 4.575 | 0.500 | -- | 0.250 | -- | 6.500 | 7.000 |

| 3 1/4 | 4.875 | 4.775 | 4.975 | 0.500 | -- | 0.250 | -- | 7.000 | 7.500 |

| 3 1/2 | 5.250 | 5.150 | 5.350 | 0.500 | -- | 0.250 | -- | 7.500 | 8.000 |

| 3 3/4 | 5.625 | 5.525 | 5.725 | 0.500 | -- | 0.250 | -- | 8.000 | 8.500 |

| 4 | 6.000 | 5.900 | 6.100 | 0.500 | -- | 0.250 | -- | 8.500 | 9.000 |

Dimensions Chart of Nuts

| Nominal Size inch | Basic Major Diameter of Thread | Width Across Flats, F | Width Across Corners, G | Thickness Heavy Hex Nuts, H | Thickness Heavy Hex Jam Nuts, H1 | Maximum Runout of Bearing Surface to Thread Axis, FIM |

|||||||||

| Heavy HEX NUTS | Heavy Hex Jam Nuts |

||||||||||||||

| Specified Proof load | |||||||||||||||

| Basic inch | Min. | Max | Min. | Max | Basic inch | Min. | Max | Basic inch | Min. | Max | Up to 150,000 psi | 150,000 psi and Greater | All Strength Levels |

||

| 1/4 | 0.2500 | 1/2 | 0.488 | 0.500 | 0.556 | 0.577 | 15/64 | 0.218 | 0.250 | 11/64 | 0.156 | 0.188 | 0.017 | 0.011 | 0.017 |

| 5/16 | 0.3125 | 9/16 | 0.546 | 0.562 | 0.622 | 0.650 | 19/64 | 0.280 | 0.314 | 13/64 | 0.186 | 0.220 | 0.020 | 0.012 | 0.020 |

| 3/8 | 0.3750 | 11/16 | 0.669 | 0.688 | 0.763 | 0.794 | 23/64 | 0.341 | 0.377 | 15/64 | 0.216 | 0.252 | 0.021 | 0.014 | 0.021 |

| 7/16 | 0.4375 | 3/4 | 0.728 | 0.750 | 0.830 | 0.866 | 27/64 | 0.403 | 0.441 | 17/64 | 0.247 | 0.285 | 0.022 | 0.015 | 0.022 |

| 1/2 | 0.5000 | 7/8 | 0.850 | 0.875 | 0.969 | 1.010 | 31/64 | 0.464 | 0.504 | 19/64 | 0.277 | 0.317 | 0.023 | 0.016 | 0.023 |

| 9/16 | 0.5625 | 15/16 | 0.909 | 0.938 | 1.037 | 1.083 | 35/64 | 0.526 | 0.568 | 21/64 | 0.307 | 0.349 | 0.024 | 0.017 | 0.024 |

| 5/8 | 0.6250 | 1 1/16 | 1.031 | 1.062 | 1.175 | 1.227 | 39/64 | 0.587 | 0.631 | 23/64 | 0.337 | 0.381 | 0.025 | 0.018 | 0.025 |

| 3/4 | 0.7500 | 1 1/4 | 1.212 | 1.250 | 1.382 | 1.443 | 47/64 | 0.710 | 0.758 | 27/64 | 0.398 | 0.446 | 0.027 | 0.020 | 0.027 |

| 7/8 | 0.8750 | 1 7/16 | 1.394 | 1.438 | 1.589 | 1.660 | 55/64 | 0.833 | 0.885 | 31/64 | 0.458 | 0.510 | 0.029 | 0.022 | 0.029 |

| 1 | 1.0000 | 1 5/8 | 1.575 | 1.625 | 1.796 | 1.876 | 63/64 | 0.956 | 1.012 | 35/64 | 0.519 | 0.575 | 0.031 | 0.024 | 0.031 |

| 1 1/8 | 1.1250 | 1 13/16 | 1.756 | 1.812 | 2.002 | 2.093 | 1 7/64 | 1.079 | 1.139 | 39/64 | 0.579 | 0.639 | 0.033 | 0.027 | 0.033 |

| 1 1/4 | 1.2500 | 2 | 1.938 | 2.000 | 2.209 | 2.309 | 1 7/32 | 1.187 | 1.251 | 23/32 | 0.687 | 0.751 | 0.035 | 0.030 | 0.035 |

| 1 3/8 | 1.3750 | 2 3/16 | 2.119 | 2.188 | 2.416 | 2.526 | 1 11/32 | 1.310 | 1.378 | 25/32 | 0.747 | 0.815 | 0.038 | 0.033 | 0.038 |

| 1 1/2 | 1.5000 | 2 3/8 | 2.300 | 2.375 | 2.622 | 2.742 | 1 15/32 | 1.433 | 1.505 | 27/32 | 0.808 | 0.880 | 0.041 | 0.036 | 0.041 |

| 1 5/8 | 1.6250 | 2 9/16 | 2.481 | 2.562 | 2.828 | 2.959 | 1 19/32 | 1.556 | 1.632 | 29/32 | 0.868 | 0.944 | 0.044 | 0.038 | 0.044 |

| 1 3/4 | 1.7500 | 2 3/4 | 2.662 | 2.750 | 3.035 | 3.175 | 1 23/32 | 1.679 | 1.759 | 31/32 | 0.929 | 1.009 | 0.048 | 0.041 | 0.048 |

| 1 7/8 | 1.8750 | 2 15/16 | 2.844 | 2.938 | 3.242 | 3.392 | 1 27/32 | 1.802 | 1.886 | 1 1/32 | 0.989 | 1.073 | 0.051 | 0.044 | 0.051 |

| 2 | 2.0000 | 3 1/8 | 3.025 | 3.125 | 3.449 | 3.608 | 1 31/32 | 1.925 | 2.013 | 1 3/32 | 1.050 | 1.138 | 0.055 | 0.047 | 0.055 |

| 2 1/4 | 2.2500 | 3 1/2 | 3.388 | 3.500 | 3.862 | 4.041 | 2 13/64 | 2.155 | 2.251 | 1 13/64 | 1.155 | 1.251 | 0.061 | 0.052 | 0.061 |

| 2 1/2 | 2.5000 | 3 7/8 | 3.750 | 3.875 | 4.275 | 4.474 | 2 29/64 | 2.401 | 2.505 | 1 29/64 | 1.401 | 1.505 | 0.068 | 0.058 | 0.068 |

| 2 3/4 | 2.7500 | 4 1/4 | 4.112 | 4.250 | 4.688 | 4.907 | 2 45/64 | 2.647 | 2.759 | 1 37/64 | 1.522 | 1.634 | 0.074 | 0.064 | 0.074 |

| 3 | 3.0000 | 4 5/8 | 4.475 | 4.625 | 5.102 | 5.340 | 2 61/64 | 2.893 | 3.013 | 1 45/64 | 1.643 | 1.763 | 0.081 | 0.070 | 0.081 |

| 3 1/4 | 3.2500 | 5 | 4.838 | 5.000 | 5.515 | 5.774 | 3 3/16 | 3.124 | 3.252 | 1 13/16 | 1.748 | 1.876 | 0.087 | 0.075 | 0.087 |

| 3 1/2 | 3.5000 | 5 3/8 | 5.200 | 5.375 | 5.928 | 6.207 | 3 7/16 | 3.370 | 3.506 | 1 15/16 | 1.870 | 2.006 | 0.094 | 0.081 | 0.094 |

| 3 3/4 | 3.7500 | 5 3/4 | 5.562 | 5.750 | 6.341 | 6.640 | 3 11/16 | 3.616 | 3.760 | 2 1/16 | 1.990 | 2.134 | 0.100 | 0.087 | 0.100 |

| 4 | 4.0000 | 6 1/8 | 5.925 | 6.125 | 6.755 | 7.073 | 3 15/16 | 3.862 | 4.014 | 2 3/16 | 2.112 | 2.264 | 0.107 | 0.093 | 0.107 |

Dimensions Chart of Washer

| Nominal Size | T | Clipped Width E, Min. | |||||||

| I.D. | O.D. | Standard | Extra Thick | ||||||

| [Note (1)] | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | [Note (2)] |

| 12 | 14.4 | 14 | 27 | 25.7 | 4.6 | 3.1 | 10 | 8 | 10.5 |

| 16 | 18.4 | 18 | 34 | 32.4 | 4.6 | 3.1 | 10 | 8 | 14 |

| 20 | 22.5 | 22 | 42 | 40.4 | 4.6 | 3.1 | 10 | 8 | 17.5 |

| 22 | 24.5 | 24 | 44 | 42.4 | 4.6 | 3.4 | 10 | 8 | 19.2 |

| 24 | 26.5 | 26 | 50 | 48.4 | 4.6 | 3.4 | 10 | 8 | 21 |

| 27 | 30.5 | 30 | 56 | S4.1 | 4.6 | 3.4 | 10 | 8 | 23.6 |

| 30 | 33.6 | 33 | 60 | 58.1 | 4.6 | 3.4 | 10 | 8 | 26.2 |

| 36 | 39.6 | 39 | 72 | 70.1 | 4.6 | 3.4 | 10 | 8 | 31.S |

| 42 | 45.6 | 45 | 84 | 81.8 | 7.2 | 4.6 | 10 | 8 | 36.7 |

| 48 | 52.7 | 52 | 95 | 92.8 | 7.2 | 4.6 | 10 | 8 | 42 |

| 56 | 62.7 | 62 | 107 | 104.8 | 8.7 | 6.1 | 10 | 8 | 49 |

| 64 | 70.7 | 70 | 118 | 115.8 | 8.7 | 6.1 | 10 | 8 | 56 |

| 72 | 78.7 | 78 | 130 | 127.5 | 8.7 | 6.1 | 10 | 8 | 63 |

| 80 | 86.9 | 86 | 142 | 139.5 | 8.7 | 6.1 | 10 | 8 | 70 |

| 90 | 96.9 | 96 | 159 | 156.5 | 8.7 | 6.1 | 10 | 8 | 78.7 |

| 100 | 107.9 | 107 | 176 | 173.5 | 8.7 | 6.1 | 10 | 8 | 87.5 |

Size Of Stainless Steel 321 Fasteners

Metric Bolt Dimensions Chart

Imperial Bolt Dimensions Chart

Size Chart of Nuts

| Nut Size (mm) | Diameter* (mm) | Height (mm) |

||

| Hex Nut | Jam Nut | Nylock Nut | ||

| 2 | 4 | 1.6 | 1.2 | - |

| 2.5 | 5 | 2 | 1.6 | - |

| 3 | 5.5 | 2.4 | 1.8 | 4 |

| 4 | 7 | 3.2 | 2.2 | 5 |

| 5 | 8 | 4 | 2.7 | 5 |

| 6 | 10 | 5 | 3.2 | 6 |

| 7 | 11 | 5.5 | 3.5 | - |

| 8 | 13 | 6.5 | 4 | 8 |

| 10 | 17 | 8 | 5 | 10 |

| 12 | 19 | 10 | 6 | 12 |

| 14 | 22 | 11 | 7 | 14 |

| 16 | 24 | 13 | 8 | 16 |

| 18 | 27 | 15 | 9 | 18.5 |

| 20 | 30 | 16 | 10 | 20 |

Size Chart of Washers

| SIZE | INSIDE DIAMETER | OUTSIDE DIAMETER | THICKNESS |

| SAE FLAT WASHERS | |||

| #6 | 5/32" | 3/8" | 3/64" |

| #8 | 3/16" | 7/16" | 3/64" |

| #10 | 7/32" | 1/2" | 3/64" |

| 1/4 | 9/32" | 5/8" | 1/16" |

| 5/16 | 11/32" | 11/16" | 1/16" |

| 3/8 | 13/32" | 13/16" | 1/16" |

| 7/16 | 15/32" | 59/64" | 1/16" |

| 1/2 | 17/32" | 1-1/16" | 3/32" |

| 9/16 | 19/32" | 1-3/16" | 3/32" |

| 5/8 | 21/32" | 1-5/16" | 3/32" |

| 3/4 | 13/16" | 1-1/2" | 9/64" |

| 7/8 | 15/16" | 1-3/4" | 9/64" |

| 1" | 1-1/16" | 2" | 9/64" |

| 1-1/8 | 1-3/16" | 2-1/4" | 9/64" |

| 1-1/4 | 1-5/16" | 2-1/2" | 5/32" |

| 1-1/2 | 1-7/16" | 3" | 3/16" |

| USS FLAT WASHERS | |||

| 3/16 | 1/4" | 9/16" | 3/64" |

| 1/4 | 5/16" | 3/4" | 1/16" |

| 5/16 | 3/8" | 7/8" | 5/64" |

| 3/8 | 7/16" | 1" | 5/64" |

| 7/16 | 1/2" | 1-1/4" | 5/64" |

| 1/2 | 9/16" | 1-3/8" | 7/64" |

| 9/16 | 5/8" | 1-1/2" | 7/64" |

| 5/8 | 11/16" | 1-3/4" | 9/64" |

| 3/4 | 13/16" | 2" | 5/32" |

| 7/8 | 15/16" | 2-1/4" | 11/64" |

| 1" | 1-1/16" | 2-1/2" | 11/64" |

| 1-1/8 | 1-1/4" | 2-3/4" | 11/64" |

| 1-1/4 | 1-3/8" | 3" | 11/64" |

| 1-3/8 | 1-1/2" | 3-1/4" | 3/16" |

| 1-1/2 | 1-5/8" | 3-1/2" | 3/16" |

| 1-5/8 | 1-3/4" | 3-3/4" | 3/16" |

| 1-3/4 | 1-7/8" | 4" | 3/16" |

| 1-7/8 | 2" | 4-1/4" | 3/16" |

| 2" | 2-1/8" | 4-1/2" | 3/16" |

| 2-1/2 | 2-5/8" | 5" | 15/64" |

| 3" | 3-1/8" | 5-1/2" | 9/32" |

Weight Chart Of Stainless Steel 321 Fasteners

| LENGTHS | #2 | #3 | #4 | #5 | #6 | #8 | #10 | #12 | 1/4″ | 5/16″ | 3/8″ |

| 1/8 | 0.40 | 0.55 | 0.70 | 1.1 | 1.4 | — | — | — | — | — | — |

| 3/16 | 0.50 | 0.70 | 0.90 | 1.2 | 1.5 | 2.5 | 3.9 | — | — | — | — |

| 1/4 | 0.60 | 0.80 | 1.00 | 1.4 | 1.7 | 2.8 | 4.3 | 5.6 | 8.5 | — | — |

| 5/16 | 0.60 | 0.90 | 1.20 | 1.5 | 1.9 | 3.1 | 4.6 | 6.1 | 9.1 | 16.7 | — |

| 3/8 | 0.70 | 0.90 | 1.30 | 1.7 | 2.1 | 3.4 | 5.0 | 6.5 | 9.8 | 17.7 | 29.2 |

| 7/16 | 0.80 | 1.00 | 1.50 | 1.9 | 2.2 | 3.6 | 5.4 | 6.9 | 10.4 | 18.8 | 30.7 |

| 1/2 | 0.80 | 1.10 | 1.60 | 2.0 | 2.4 | 3.9 | 5.8 | 7.4 | 11.1 | 19.8 | 32.2 |

| 9/16 | 0.90 | 1.20 | 1.70 | 2.2 | 2.6 | 4.2 | 6.2 | 7.8 | 11.7 | 20.9 | 33.6 |

| 5/8 | 1.00 | 1.30 | 1.80 | 2.3 | 2.8 | 4.5 | 6.6 | 8.3 | 12.4 | 21.9 | 35.1 |

| 3/4 | 1.10 | 1.50 | 2.10 | 2.6 | 3.2 | 5.0 | 7.3 | 9.2 | 13.6 | 24.0 | 38.0 |

| 7/8 | 1.30 | 1.70 | 2.30 | 3.0 | 3.5 | 5.6 | 8.1 | 10.1 | 14.9 | 26.1 | 41.0 |

| 1″ | 1.40 | 1.90 | 2.50 | 3.4 | 3.9 | 6.2 | 8.9 | 11.0 | 16.1 | 28.8 | 44.0 |

| 1-1/8″ | 1.50 | 2.00 | 2.80 | 3.8 | 4.3 | 6.7 | 9.6 | 11.9 | 17.4 | 30.2 | 47.0 |

| 1-1/4″ | 1.60 | 2.20 | 3.00 | 4.1 | 4.6 | 7.3 | 10.4 | 12.8 | 18.7 | 32.3 | 49.8 |

| 1-1/2″ | 1.80 | 2.50 | 3.50 | 4.7 | 5.3 | 8.3 | 11.9 | 14.7 | 21.2 | 36.5 | 55.8 |

| 1-3/4″ | 2.10 | 2.90 | 4.00 | 5.3 | 6.1 | 9.4 | 13.5 | 16.5 | 23.7 | 40.7 | 61.7 |

| 2″ | 2.40 | 3.30 | 4.50 | 6.0 | 6.8 | 10.6 | 15.0 | 18.3 | 26.2 | 44.8 | 67.6 |

| 2-1/4″ | 2.60 | 3.60 | 5.00 | 6.7 | 7.6 | 11.8 | 16.6 | 20.1 | 28.8 | 19.0 | 73.5 |

| 2-1/2″ | 2.80 | 3.90 | 5.50 | 7.3 | 8.3 | 12.9 | 18.1 | 22.0 | 31.3 | 53.2 | 79.5 |

| 2-3/4″ | 3.10 | 4.30 | 6.00 | 7.9 | 9.1 | 13.9 | 19.7 | 23.8 | 33.9 | 57.3 | 85.3 |

| 3″ | 3.40 | 4.70 | 6.50 | 8.6 | 9.8 | 15.0 | 21.2 | 25.6 | 36.4 | 61.5 | 91.3 |

industrial use fitting for Stainless Steel 321 Fasteners

Price Of Stainless Steel 321 Fasteners

| Stainless Steel Hex Bolt | USD $2.0 - $10.09 / kg (FOB Price) on request |

| Stainless Steel Hex Nut | USD $2.0 - $10.09 / kg (FOB Price) on request |

| Stainless Steel Screw | USD $2.0 - $10.09 / kg (FOB Price) on request |

| Stainless Steel Spring Washer | USD $2.0 - $10.09 / kg (FOB Price) on request |

| Stainless Steel Stud Bolt | USD $2.0 - $10.09 / kg (FOB Price) on request |

Application Of Stainless Steel 321 Fasteners

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Stainless Steel 321 Fasteners

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

Packing Of Stainless Steel 321 Fasteners

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

ASTM A193 SS 321 Hex Bolts Weight Chart, 321 SS Hex Head Bolts Weight Calculator, SS 321 T Nuts At Factory Price, ASME SA193 SS 321 Hex Nuts At Factory Price, SS 321 Stud Bolts Price Per Kg, 321 SS Rivet Nuts At Factory Price, DIN 1.4541 Torx Bolts Catalogue, UNS S32100 Forged Hook Bolts Price List In India, DIN 1.4541 Tab Washer Price List, SS 321 Spring Washer Price Per Kg, Stainless Steel 321 Carriage Bolts Price List, UNS S32100 Plain Washer Weight Chart.

UNS S32100 Drywall screw Manufacturer in Daman, DIN 1.4541 Self-tapping-screw Stockist in Gujarat, 321 SS Rivet Nuts Supplier in Hyderabad, DIN 1.4541 Torx Bolts Stockist in Ahmedabad, SS 321 Spring Washer Stockist in Nashik, UNS S32100 Forged Hook Bolts Manufacturer in Mumbai, ASME SA193 SS 321 Hex Nuts Stockist in Chennai, SS 321 T Nuts Supplier in Pune, DIN 1.4541 Tab Washer Manufacturer in Vadodara, UNS S32100 Plain Washer Stockist in Bangalore, 321 SS Hex Head Bolts Supplier in Hyderabad, 321 SS Countersunk Bolts Stockist in Bharuch.

SS 321 Roofing screws Manufacturer in Israel, ASME SA193 SS 321 Sealing washer Exporter in Lebanon, UNS S32100 Drywall screw Manufacturer in Italy, Stainless Steel 321 Pocket hole screws Exporter in Iran, 321 SS Countersunk Bolts Stockist in Australia, 321 SS 12 point nut Stockist in Egypt, DIN 1.4541 Star washer Supplier in Jordan, DIN 1.4541 Tab Washer Manufacturer in Vietnam, DIN 1.4541 Self-tapping-screw Stockist in UK, UNS S32100 Captive-nuts Stockist in Saudi Arabia, SS 321 Spring Washer Stockist in Oman, ASTM A193 SS 321 Grub screw Supplier in Iraq.

Stainless Steel Fasteners

- Stainless Steel 304/ 304L/ 304H Fasteners

- Stainless Steel 309 Fasteners

- Stainless Steel 310/ 310S Fasteners

- Stainless Steel 316/ 316L/ 316Ti Fasteners

- Stainless Steel 317/ 317L Fasteners

- Stainless Steel 321 Fasteners

- Stainless Steel 347/ 347H Fasteners

- Stainless Steel 410/ 420/ 430 Fasteners

- Stainless Steel 446 Fasteners

- Stainless Steel 904L Fasteners

- Stainless Steel 15-5 PH Fasteners

- Stainless Steel 17-4 PH Fasteners