Duplex 2205/ UNS 32205/ UNS 31803 Forged fitting

32205 Duplex Union, ASME SA182 Duplex 2205 Full Coupling, Duplex 2205 Threaded 45 Lateral Tee, DIN 1.4462 Threaded Street Elbow, Duplex 2205 Tee, 2205 Duplex Reducing Tee, ASME SA182 Duplex 2205 Reducer Insert.

About Duplex 2205/ UNS 32205/ UNS 31803 Forged fitting

The alloy referred to as DUPLEX 2205 or UNS S32205 is ferritic and austenitic stainless steel with two distinct phases. Its dual microstructure makes it both strong in terms of strength and resistant when faced with corrosion due to its stress-corrosion cracking resistance – making this duplex stainless steel particularly useful for industries such as chemical processing, oil & gas exploration or marine applications where saltwater may be present. DUPLEX 2205 is the ideal choice for marine and other harsh environments due to its impressive ability to resist pitting and crevice corrosion. Its superior strength-to-weight ratio makes it perfect for structures like bridges, offshore buildings, pressure vessels, and more. It is highly resistant to chloride stress corrosion cracking which often occurs in industrial environments, and offers incredible yield strength, toughness, and fatigue resistance capabilities.

UNS 31803, also called F51 or Duplex 2205, is a duplex stainless steel alloy composed of 22% chromium, 5% nickel, and 3% molybdenum. This alloy exhibits a remarkable ferritic-austenitic transformation that provides remarkable strength and considerable corrosion resistance, making it the optimal choice for situations calling for protection from stress corrosion cracking.

Thanks to its remarkable strength-to-weight ratio, UNS S31803 is a popular material choice for bridges, offshore structures, and pressure vessels. It’s also widely used in chemically hazardous environments, such as petroleum and gas industries, and around seawater. We can rely on this metal because of its outstanding resistance to pitting crevice corrosion even under the most corrosive conditions like coastal areas; it’s also incredibly tough against chloride stress corrosion cracking which is often found in industrial locations.

ASME SA182 Duplex 2205 Reducer Insert Exporter, Duplex 2205 Hex Plug Stockist, Duplex 2205 Tee Supplier, 32205 Duplex Threaded Equal Manufacturer, UNS S31803 Threaded Unequal Stockist.

Specification of Duplex 2205/ UNS 32205/ UNS 31803 Forged fitting

| Specification | ASTM A182 / ASME SA182 |

| Dimension Standard | ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799 |

| Size | 1/8" NB to 4" NB |

| Type | Socketweld Fittings, Screwed-Threaded Fittings |

| Pressure-Temperature Class | Threaded End - 2000 /3000/ 6000 LBS. Socket-weld End - 3000 / 6000/ 9000 LBS. |

Ready stock of available for Duplex 2205/ UNS 32205/ UNS 31803 Forged fitting

Equivalent Grades of Duplex 2205/ UNS 32205/ UNS 31803 Forged fitting

| STANDARD | WERKSTOFF NR. | UNS |

| Duplex 2205 | 1.4462 | S31803 / S32205 |

| Duplex S32205 | 1.4462 | S31803 / S32205 |

| Duplex S31803 | 1.4462 | S31803 / S32205 |

Chemical Composition of Duplex 2205/ UNS 32205/ UNS 31803 Forged fitting

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| 2205 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21.0 – 23.0 | 2.50 - 3.50 | 4.50 – 6.50 | 0.8 – 0.20 | 63.54 min |

| 32205 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21.0 – 23.0 | 2.50 - 3.50 | 4.50 – 6.50 | 0.8 – 0.20 | 63.54 min |

| 31803 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21.0 – 23.0 | 2.50 - 3.50 | 4.50 – 6.50 | 0.8 – 0.20 | 63.54 min |

Mechanical Properties of Duplex 2205/ UNS 32205/ UNS 31803 Forged fitting

| Grades | Density (g/cm 3) | Melting Point | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

| 2205 | 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000 , MPa – 800 | Psi – 80000 , MPa – 550 | 15 % |

| 32205 | 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000 , MPa – 800 | Psi – 80000 , MPa – 550 | 15 % |

| 31803 | 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000 , MPa – 800 | Psi – 80000 , MPa – 550 | 15 % |

Other Types of Duplex 2205/ UNS 32205/ UNS 31803 Forged fitting

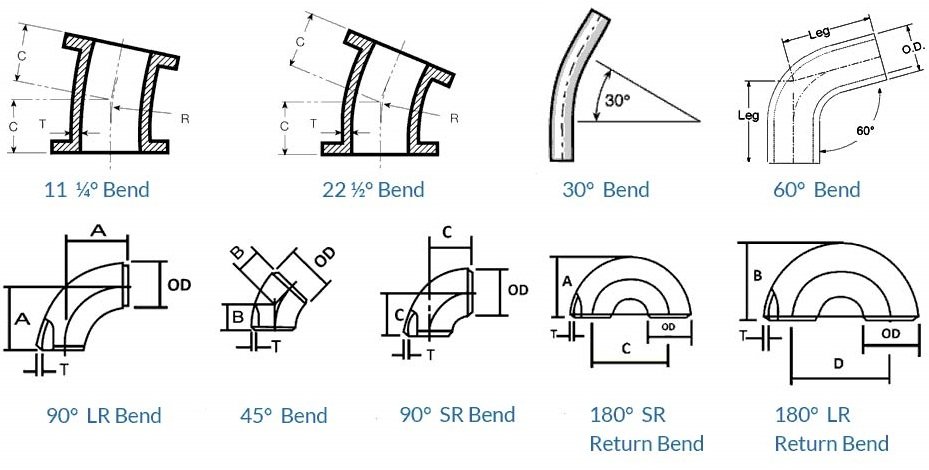

Dimensions Standard Of Duplex 2205/ UNS 32205/ UNS 31803 Forged fitting

| ASME b16.9 Fittings Normal Pipe Size | ANSI b16 9 Pipe Fitting O D Y | Wall Thickness T (Pipe Elbow Sch.) | LR 45 Deg Elbows Centre to Face B | SR 45 Deg Elbows Weight | LR 90 Deg Elbows Centre to Face A | LR 90 Deg Elbows Weight In Below | SR 90 Deg Elbows Centre to Face A | SR 90 Deg Elbows Weight In Below | ||

| mm | inch | mm | mm | Schedule | mm | kg | mm | kg | mm | kg |

| 15 | 1/2” | 21.3 | 2.78 | STD | 15.9 | 0.04 | 38.1 | 0.08 | – | – |

| 3.73 | X.S | 15.9 | 0.05 | 38.1 | 0.10 | – | – | |||

| 20 | 3/4” | 26.7 | 2.87 | STD | 11.1 | 0.04 | 28.6 | 0.08 | – | – |

| 3.91 | X.S | 11.1 | 0.05 | 28.6 | 0.11 | – | – | |||

| 25 | 1” | 33.4 | 3.38 | STD | 22.2 | 0.09 | 38.1 | 0.15 | 25.4 | 0.11 |

| 4.55 | X.S | 22.2 | 0.11 | 38.1 | 0.19 | 25.4 | 0.14 | |||

| 32 | 11/4” | 42.2 | 3.56 | STD | 25.4 | 0.14 | 47.6 | 0.28 | 31.75 | 0.18 |

| 4.85 | X.S | 25.4 | 0.2 | 47.6 | 0.39 | 31.75 | 0.24 | |||

| 40 | 11/2” | 48.3 | 3.68 | STD | 28.6 | 0.2 | 57.1 | 0.4 | 38.1 | 0.26 |

| 5.08 | X.S | 28.6 | 0.25 | 57.1 | 0.5 | 38.1 | 0.35 | |||

| 50 | 2” | 60.3 | 3.91 | STD | 34.9 | 0.36 | 76.2 | 0.72 | 50.8 | 0.5 |

| 5.54 | X.S | 34.9 | 0.5 | 76.2 | 1.0 | 50.8 | 0.68 | |||

| 65 | 21/2” | 73.0 | 5.16 | STD | 44.4 | 0.73 | 95.2 | 1.46 | 63.5 | 0.95 |

| 7.01 | X.S | 44.4 | 0.91 | 95.2 | 1.82 | 63.5 | 1.27 | |||

| 80 | 3” | 88.9 | 5.49 | STD | 50.8 | 1.1 | 114.3 | 2.18 | 76.2 | 1.45 |

| 7.62 | X.S | 50.8 | 1.45 | 114.3 | 2.86 | 76.2 | 1.95 | |||

| 100 | 4” | 114.3 | 6.02 | STD | 63.5 | 2.1 | 152.4 | 4.2 | 101.6 | 2.8 |

| 8.56 | X.S | 63.5 | 2.9 | 152.4 | 5.7 | 101.6 | 3.9 | |||

| 125 | 5” | 141.3 | 6.65 | STD | 79.4 | 3.4 | 190.0 | 6.8 | 127.0 | 4.8 |

| 9.5 | X.S | 79.4 | 5.0 | 190.0 | 10.0 | 127.0 | 6.5 | |||

| 150 | 6” | 168.3 | 7.11 | STD | 95.2 | 5.1 | 229.0 | 10.1 | 152.4 | 6.8 |

| 10.97 | X.S | 95.2 | 7.7 | 229.0 | 15.3 | 152.4 | 10.2 | |||

| 200 | 8” | 219.1 | 8.18 | STD | 127.0 | 10.2 | 305.0 | 20.4 | 203.0 | 13.6 |

| 12.7 | X.S | 127.0 | 15.5 | 305.0 | 30.9 | 203.0 | 20.9 | |||

| 250 | 10” | 273.9 | 9.27 | STD | 159.0 | 18.1 | 381.0 | 36.1 | 254.0 | 24.1 |

| 12.7 | X.S | 159.0 | 24.4 | 381.0 | 48.8 | 254.0 | 32.5 | |||

| 300 | 12” | 323.9 | 9.52 | STD | 190.0 | 26.6 | 457.0 | 53.1 | 305.0 | 35.4 |

| 12.7 | X.S | 190.0 | 35.0 | 457.0 | 70.0 | 305.0 | 46.7 | |||

| 350 | 14” | 355.6 | 9.52 | STD | 222.0 | 34.1 | 533.0 | 68.1 | 356.0 | 45.4 |

| 12.7 | X.S | 222.0 | 45.0 | 533.0 | 90.0 | 356.0 | 60.0 | |||

| 400 | 16” | 406.4 | 9.52 | STD | 254.0 | 45.0 | 610.0 | 89.3 | 406.0 | 59.5 |

| 12.7 | X.S | 254.0 | 59.0 | 610.0 | 118.0 | 406.0 | 78.7 | |||

| 450 | 18” | 457.0 | 9.52 | STD | 286.0 | 56.5 | 686.0 | 113.0 | 457.0 | 75.6 |

| 12.7 | X.S | 286.0 | 75.0 | 686.0 | 150.0 | 457.0 | 100.0 | |||

| 500 | 20” | 508.0 | 9.52 | STD | 318.0 | 85.0 | 762.0 | 140.0 | 508.0 | 93.5 |

| 12.7 | X.S | 318.0 | 112.5 | 762.0 | 186.0 | 508.0 | 124.0 | |||

| 600 | 24” | 610.00 | 9.52 | STD | 381.0 | 101.5 | 914.0 | 203.0 | 610.0 | 135.0 |

| 12.7 | X.S | 381.0 | 134.5 | 914.0 | 269.0 | 610.0 | 179.0 | |||

Size Of Duplex 2205/ UNS 32205/ UNS 31803 Forged fitting

| NPS (inch) | Pipe Schedule. | OD (inch) | Wall Thick. (in) | Temperature | ||||

| 100 Fitting | 200 Fitting | 300 Fitting | 400 Fitting | 500 Fitting | ||||

| Allowable Stress | ||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | ||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 |

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | |

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | |

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 |

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | |

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | |

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 |

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | |

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | |

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 |

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | |

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | |

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 |

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | |

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | |

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 |

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | |

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | |

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 |

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | |

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | |

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 |

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | |

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | |

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 |

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | |

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | |

Weight Chart Of Duplex 2205/ UNS 32205/ UNS 31803 Forged fitting

| Normal Pipe Sizes | A | B | QTY | Weight In KG |

| ¼ | 0.81 | 0.88 | 160 | 0.20 |

| ⁄ | 0.97 | 1.00 | 130 | 0.26 |

| ½ | 1.12 | 1.31 | 100 | 0.57 |

| ¾ | 1.31 | 1.5 | 75 | 0.71 |

| 1 | 1.5 | 1.81 | 40 | 1.08 |

| 1 ¼ | 1.75 | 2.19 | 25 | 1.68 |

| 1 ½ | 2.00 | 2.44 | 18 | 2.38 |

| 2 | 2.38 | 2.97 | 10 | 3.55 |

| 2 ½ | 3.00 | 3.62 | 4 | 6.22 |

| 3 | 3.38 | 4.31 | 2 | 10.36 |

| 4 | 4.19 | 5.75 | 1 | 23.91 |

Pressure Rating Of Duplex 2205/ UNS 32205/ UNS 31803 Forged fitting

| Pressure-Temperature | |||||

| Temperature | Class | ||||

| 150 | 300 | ||||

| 1/4 - 1 inch. | 1 1/4 - 2 inch. | 2 1/2 - 3 inch. | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | - | 935 | 750 | 560 |

| 450 | 232 | - | 725 | 600 | 475 |

| 500 | 260 | - | 510 | 450 | 385 |

| 550 | 288 | - | 300 | 300 | 300 |

industrial use fitting for Duplex 2205/ UNS 32205/ UNS 31803 Forged fitting

Price Of Duplex 2205/ UNS 32205/ UNS 31803 Forged fitting

| Duplex and Super Duplex Elbow | USD $10.21 - $35.51 / Piece (FOB Price) on request |

| Duplex and Super Duplex Equal Tee | USD $10.21 - $35.51 / Piece (FOB Price) on request |

| Duplex and Super Duplex Reducing Tee | USD $10.21 - $35.51 / Piece (FOB Price) on request |

| Duplex and Super Duplex Cross | USD $10.21 - $35.51 / Piece (FOB Price) on request |

| Duplex and Super Duplex Cap | USD $10.21 - $35.51 / Piece (FOB Price) on request |

Application Of Duplex 2205/ UNS 32205/ UNS 31803 Forged fitting

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Duplex 2205/ UNS 32205/ UNS 31803 Forged fitting

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

Packing Of Duplex 2205/ UNS 32205/ UNS 31803 Forged fitting

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates