Duplex 2205/ UNS 32205/ UNS 31803 Flanges

UNS S31803 Lap Joint Flanges, 2205 Duplex Flat Flanges, UNS S32205 WNRF Flanges, Duplex 32205 Slip On Flange, 31803 Duplex Weldneck Flanges, 2205 Duplex Spades Ring Spacers Flanges, Duplex 2205 Blind Flange.

About Duplex 2205/ UNS 32205/ UNS 31803 Flanges

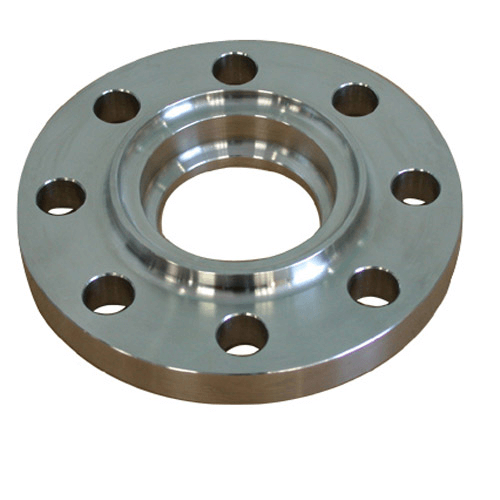

The Duplex 2205 Flanges are made of dual-nature steel with ferritic microstructures. The material is resistant to corrosion under chloride stress. In corrosive settings, it is employed. One of the low-pressure varieties of the flanges is the Class 150 UNS S31803 Flange. The classes are based on the pressure capacity of the flanges. The Duplex UNS S32205 Orifice Flange, the most popular type of duplex orifice flange, is one of the several flange variations. Depending on the need, different flanges have different applications.

ASTM A182 Duplex S31803 Flanges are employed for high-pressure applications and high-pressure vessels. When working in chloride-rich conditions, the temperature can reach 150 degrees Celsius. This material grade includes welded, bolted, and threaded flanges. Several sorts, such as the Duplex SAF 2205 Flanges, are strengthened by having a socket welded onto them. The material’s minimum yield and tensile strengths are 448 MPa and 621 MPa, respectively. The Duplex Steel S31803/S32205 Flange increases the surface for attachment. It is applied as a pair in two parts.

There are ring-type joint flanges, flat faces, and raised face flanges. For various connections, each distinct kind is required. With more surfaces, the face types facilitate welding and fastening techniques. To seal a pipeline, utilize the DIN 1.4462 Flange. Carbon, manganese, silicon, phosphorus, sulfur, chromium, molybdenum, nickel, and nitrogen make up the typical duplex flange material. With a melting temperature of 1420 degrees Celsius, these Flanges and other flanges are solid. For applications involving high temperatures and high temperatures, the flanges adhere to the ASTM A182 standard.

Features of Duplex 2205/UNS 32205/UNS S31803 Flanges :

With more than 80% of the duplex stainless-steel market, 2205 is the Duplex stainless steel that is most frequently utilized. In various settings where 316L is typically utilized, the 2205 alloy offers improved corrosion resistance with the added benefit of higher yield strength. To make sure that no harmful phases, like sigma, are present in the supplied product, all 2205 alloys are metallic substrate inspected. It is frequently utilized as welded pipe or tubular parts. The alloy has also been employed as a moulded and welded sheet product when protection against erosion and chloride SCC is essential. This uncommon Duplex 2205 Flanges alloy is used in the petrochemical processing and exploration of oil and gas applications. Due to their capacity to endure a high mechanical strain in saltwater, these Flanges are essential to mechanical assembly and infrastructure.

Offshore oil drilling companies, aircraft exhaust manifolds, petrochemicals, power generation, gas processing, pharmaceuticals, specialty chemicals, pharmaceutical machinery, heat exchangers, and seawater equipment are some of the industries that use duplex steel flanges.

2205 Duplex Spades Ring Spacers Flanges Manufacturer, DIN 1.4462 Forging Facing Flanges Supplier, ASME SA182 Duplex 31803 Spectacle Blind Flanges Exporter, 32205 Duplex Weldo / Nipo Flanges Exporter.

Specification of Duplex 2205/ UNS 32205/ UNS 31803 Flanges

| Specification | ASTM A182 / ASME SA182 |

| Dimension Standard | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| DIN Flanges | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673. |

| JIS Flanges | JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K |

| BS Flanges | BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H. |

Ready stock of Flanges available for Duplex 2205/ UNS 32205/ UNS 31803 Flanges

Equivalent Grades of Duplex 2205/ UNS 32205/ UNS 31803 Flanges

| STANDARD | WERKSTOFF NR. | UNS |

| Duplex 2205 | 1.4462 | S31803 / S32205 |

| Duplex S32205 | 1.4462 | S31803 / S32205 |

| Duplex S31803 | 1.4462 | S31803 / S32205 |

Chemical Composition of Duplex 2205/ UNS 32205/ UNS 31803 Flanges

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| 2205 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21.0 – 23.0 | 2.50 - 3.50 | 4.50 – 6.50 | 0.8 – 0.20 | 63.54 min |

| 32205 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21.0 – 23.0 | 2.50 - 3.50 | 4.50 – 6.50 | 0.8 – 0.20 | 63.54 min |

| 31803 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21.0 – 23.0 | 2.50 - 3.50 | 4.50 – 6.50 | 0.8 – 0.20 | 63.54 min |

Mechanical Properties of Duplex 2205/ UNS 32205/ UNS 31803 Flanges

| Grades | Density (g/cm 3) | Melting Point | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

| 2205 | 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000 , MPa – 800 | Psi – 80000 , MPa – 550 | 15 % |

| 32205 | 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000 , MPa – 800 | Psi – 80000 , MPa – 550 | 15 % |

| 31803 | 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000 , MPa – 800 | Psi – 80000 , MPa – 550 | 15 % |

Other Types of Flanges of Duplex 2205/ UNS 32205/ UNS 31803 Flanges

Dimensions Standard Of Duplex 2205/ UNS 32205/ UNS 31803 Flanges

| Nominal Size | Outside Diameter (OD) | Min. Thickness (T) | RF Dia. (R) | No. of Bolt Holes | Diameter of Holes | Bolt Circle (BC) | SO Bore ID (SB) | WN Bore ID (WB) | Dia. Hub Base (HB) | Dia. of Hub Top (HT) | SO LTH (SL) | WN LTH (WL) |

| 1⁄2 | 3.50 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.50 | 1.05 | 0.56 | 2.00 |

| 1 | 4.25 | 0.50 | 2.00 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.50 | 4 | 0.62 | 3.50 | 1.70 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5.00 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.90 | 0.81 | 2.38 |

| 2 | 6.00 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7.00 | 0.81 | 4.12 | 4 | 0.75 | 5.50 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.50 | 0.88 | 5.00 | 4 | 0.75 | 6.00 | 3.57 | 3.07 | 4.25 | 3.50 | 1.12 | 2.69 |

| 31⁄2 | 8.50 | 0.88 | 5.50 | 8 | 0.75 | 7.00 | 4.07 | 3.55 | 4.81 | 4.00 | 1.19 | 2.75 |

| 4 | 9.00 | 0.88 | 6.19 | 8 | 0.75 | 7.50 | 4.57 | 4.03 | 5.31 | 4.50 | 1.25 | 2.94 |

| 5 | 10.00 | 0.88 | 7.31 | 8 | 0.88 | 8.50 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11.00 | 0.94 | 8.50 | 8 | 0.88 | 9.50 | 6.72 | 6.07 | 7.56 | 6.63 | 1.50 | 3.44 |

| 8 | 13.50 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16.00 | 1.12 | 12.75 | 12 | 1.00 | 14.25 | 10.88 | 10.02 | 12.00 | 10.75 | 1.88 | 3.94 |

| 12 | 19.00 | 1.19 | 15.00 | 12 | 1.00 | 17.00 | 12.88 | 12.00 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21.00 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14.00 | 2.19 | 4.94 |

| 16 | 23.50 | 1.38 | 18.50 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18.00 | 16.00 | 2.44 | 4.94 |

| 18 | 25.00 | 1.50 | 21.00 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18.00 | 2.62 | 5.44 |

| 20 | 27.50 | 1.62 | 23.00 | 20 | 1.25 | 25.00 | 20.20 | 19.25 | 22.00 | 20.00 | 2.81 | 5.62 |

| 22 | 29.50 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22.00 | 3.07 | 5.82 |

| 24 | 32.00 | 1.81 | 27.25 | 20 | 1.38 | 29.50 | 24.25 | 23.25 | 26.12 | 24.00 | 3.19 | 5.94 |

Size Of Duplex 2205/ UNS 32205/ UNS 31803 Flanges

| Nom. Pipe Size | o | T1 | R | x | No.2/Dia. of Holes | Bolt Circle Dia. | L21 | H | B23 | L | B | r | L34 | B3 | D |

| 1/2 | 3.50 | 0.44 | 1.38 | 1.19 | 4-0.62 | 2.38 | 1.88 | 0.84 | 0.62 | 0.62 | 0.88 | 0.12 | 0.62 | 0.90 | 0.38 |

| 3/4 | 3.88 | 0.50 | 1.69 | 1.50 | 4-0.62 | 2.75 | 2.06 | 1.05 | 0.82 | 0.62 | 1.09 | 0.12 | 0.62 | 1.11 | 0.44 |

| 1 | 4.25 | 0.56 | 2.00 | 1.94 | 4-0.62 | 3.12 | 2.19 | 1.32 | 1.05 | 0.69 | 1.36 | 0.12 | 0.69 | 1.38 | 0.50 |

| 1-1/4 | 4.62 | 0.62 | 2.50 | 2.31 | 4-0.62 | 3.50 | 2.25 | 1.66 | 1.38 | 0.81 | 1.70 | 0.19 | 0.81 | 1.72 | 0.56 |

| 1-1/2 | 5.00 | 0.68 | 2.88 | 2.56 | 4-0.62 | 3.88 | 2.44 | 1.90 | 1.61 | 0.88 | 1.95 | 0.25 | 0.88 | 1.97 | 0.62 |

| 2 | 6.00 | 0.75 | 3.62 | 3.06 | 4-0.75 | 4.75 | 2.50 | 2.38 | 2.07 | 1.00 | 2.44 | 0.31 | 1.00 | 2.46 | 0.69 |

| 2-1/2 | 7.00 | 0.88 | 4.12 | 3.56 | 4-0.75 | 5.50 | 2.75 | 2.88 | 2.47 | 1.12 | 2.94 | 0.31 | 1.12 | 2.97 | 0.75 |

| 3 | 7.50 | 0.94 | 5.00 | 4.25 | 4-0.75 | 6.00 | 2.75 | 3.50 | 3.07 | 1.19 | 3.57 | 0.38 | 1.19 | 3.60 | 0.81 |

| 3-1/2 | 8.50 | 0.94 | 5.50 | 4.81 | 8-0.75 | 7.00 | 2.81 | 4.00 | 3.55 | 1.25 | 4.07 | 0.38 | 1.25 | 4.10 | 0.88 |

| 4 | 9.00 | 0.94 | 6.19 | 5.31 | 8-0.75 | 7.50 | 3.00 | 4.50 | 4.03 | 1.31 | 4.57 | 0.44 | 1.31 | 4.60 | 0.94 |

| 5 | 10.00 | 0.94 | 7.31 | 6.44 | 8-0.88 | 8.50 | 3.50 | 5.56 | 5.05 | 1.44 | 5.66 | 0.44 | 1.44 | 5.69 | 0.94 |

| 6 | 11.00 | 1.00 | 8.50 | 7.56 | 8-0.88 | 9.50 | 3.50 | 6.63 | 6.07 | 1.56 | 6.72 | 0.50 | 1.56 | 6.75 | 1.06 |

| 8 | 13.50 | 1.12 | 10.62 | 9.69 | 8-0.88 | 11.75 | 4.00 | 8.63 | 7.98 | 1.75 | 8.72 | 0.50 | 1.75 | 8.75 | 1.25 |

| 10 | 16.00 | 1.19 | 12.75 | 12.00 | 12-1.00 | 14.25 | 4.00 | 10.75 | 10.02 | 1.94 | 10.88 | 0.50 | 1.94 | 10.92 | 1.31 |

| 12 | 19.00 | 1.25 | 15.00 | 14.38 | 12-1.00 | 17.00 | 4.50 | 12.75 | 12.00 | 2.19 | 12.88 | 0.50 | 2.19 | 12.92 | 1.56 |

| 14 | 21.00 | 1.38 | 16.25 | 15.75 | 12-1.12 | 18.75 | 5.00 | 14.00 | 13.25 | 2.25 | 14.14 | 0.50 | 3.12 | 14.18 | 1.63 |

| 16 | 23.50 | 1.44 | 18.50 | 18.00 | 16-1.12 | 21.25 | 5.00 | 16.00 | 15.25 | 2.50 | 16.16 | 0.50 | 3.44 | 16.19 | 1.75 |

| 18 | 25.00 | 1.56 | 21.00 | 19.88 | 16-1.25 | 22.75 | 5.50 | 18.00 | 17.25 | 2.69 | 18.18 | 0.50 | 3.81 | 18.20 | 1.94 |

| 20 | 27.50 | 1.69 | 23.00 | 22.00 | 20-1.25 | 25.00 | 5.69 | 20.00 | 19.25 | 2.88 | 20.20 | 0.50 | 4.06 | 20.25 | 2.13 |

| 22 | 29.50 | 1.81 | 25.25 | 24.25 | 20-1.38 | 27.25 | 5.88 | 22.00 | 21.25 | 3.13 | 22.22 | 0.50 | 4.25 | 22.25 | 2.38 |

| 24 | 32.00 | 1.88 | 27.25 | 26.12 | 20-1.38 | 29.50 | 6.00 | 24.00 | 23.25 | 3.25 | 24.25 | 0.50 | 4.38 | 24.25 | 2.50 |

Weight Chart Of Duplex 2205/ UNS 32205/ UNS 31803 Flanges

| Standard Of Flanges | Class Of Flanges | Diameter Of Flanges | Diameter Of Bolt Circle | Bolts Number | Size Of Bolt | Bolt Hole Diameter |

| AS4087 Flanges | PN14 Flanges | 95 | 67 | 4 | M12 | 14 |

| AS 2129 Flange | Table C Flanges | 95 | 67 | 4 | 13 | 14 |

| Table D Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table E Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table F Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table H Flanges | 114 | 83 | 4 | 16 | 17 | |

| Table J Flanges | 114 | 83 | 4 | 16 | 17 | |

| ANSI B16.5 Flanges | ANSI 150 Flanges | 89 | 60 | 4 | 13 | 16 |

| ANSI 300 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 600 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 900 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ANSI 1500 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ISO 7005 (DIN) Flange | PN6 Flanges | 80 | 55 | 4 | M10 | 11 |

| PN10 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN16 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN20 Flanges | 90 | 60.5 | 4 | M14 | 16 | |

| PN25 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN40 Flanges | 95 | 65 | 4 | M12 | 14 |

Pressure Rating Of Duplex 2205/ UNS 32205/ UNS 31803 Flanges

| Temp. ℃ | Pressure-ASME temperature rating for B16.47 by class, bar | |||||

| 75 | 150 | 300 | 400 | 600 | 900 | |

| -29 to 38 | 10.0 | 20.0 | 51.7 | 68.9 | 103.4 | 155.1 |

| 50 | 9.8 | 19.5 | 51.7 | 68.9 | 103.4 | 155.1 |

| 100 | 8.8 | 17.7 | 50.7 | 67.5 | 101.3 | 152.0 |

| 150 | 7.9 | 15.8 | 45.9 | 61.2 | 91.9 | 137.8 |

| 200 | 6.9 | 13.8 | 42.7 | 56.9 | 85.3 | 128.0 |

| 250 | 6.0 | 12.1 | 40.5 | 53.9 | 80.9 | 121.4 |

| 300 | 5.1 | 10.2 | 38.9 | 51.8 | 77.7 | 116.6 |

industrial use flanges for Duplex 2205/ UNS 32205/ UNS 31803 Flanges

Price Of Duplex 2205/ UNS 32205/ UNS 31803 Flanges

| Duplex and Super Duplex Forged Flanges | USD $10.20 - $35.50 / Piece (FOB Price) on request |

| Duplex and Super Duplex Blind Flanges | USD $10.20 - $35.50 / Piece (FOB Price) on request |

| Duplex and Super Duplex Slip On Flange | USD $10.20 - $35.50 / Piece (FOB Price) on request |

| Duplex and Super Duplex Socketweld Flanges | USD $10.20 - $35.50 / Piece (FOB Price) on request |

| Duplex and Super Duplex Long Weld Neck Flanges | USD $10.20 - $35.50 / Piece (FOB Price) on request |

Application Of Duplex 2205/ UNS 32205/ UNS 31803 Flanges

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Duplex 2205/ UNS 32205/ UNS 31803 Flanges

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

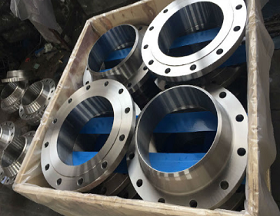

Packing Of Duplex 2205/ UNS 32205/ UNS 31803 Flanges

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

DIN 1.4462 Reducing Flanges Price List, UNS S32205 WNRF Flanges Price List In India, DIN 1.4462 Forging Facing Flanges Price List In India, ASME SA182 Duplex 31803 Spectacle Blind Flanges Weight Chart, 31803 Duplex Weldneck Flanges Weight Calculator, Duplex 32205 Weld Neck Flanges A/ B Price List, 2205 Duplex Expander Flanges Weight Calculator, ASTM A182 Duplex 2205 Forged Flanges Weight Chart, DIN 1.4462 RTJ Flanges Catalogue, UNS S31803 Orifice Flanges Weight Chart, Duplex 31803 Groove & Tongue Flanges Price Per Kg, ASTM A182 Duplex 2205 SORF Flanges Weight Chart, UNS S31803 Screwed Flanges Weight Calculator.

Duplex 31803 Groove & Tongue Flanges Stockist in Nashik, UNS S31803 Lap Joint Flanges Manufacturer in Mumbai, Duplex 2205 Longweld Neck Flange Supplier in Pune, 2205 Duplex Expander Flanges Stockist in Kerla, UNS S32205 WNRF Flanges Stockist in Karnataka, 2205 Duplex Spades Ring Spacers Flanges Manufacturer in Ahmedabad, 2205 Duplex Flat Flanges Stockist in Bharuch, UNS S32205 Loose Flanges Manufacturer in Daman, DIN 1.4462 RTJ Flanges Stockist in Gujarat, Duplex 32205 Weld Neck Flanges A/ B Exporter in Punjab, UNS S31803 Screwed Flanges Stockist in Nagpur, Duplex 2205 Flanges Bolts Exporter in Patna, DIN 1.4462 Threaded Flanges Stockist in Ahmedabad, Duplex 32205 Square Flanges Exporter in Kanpur.

32205 Duplex Weldo / Nipo Flanges Exporter in Indonesia, UNS S32205 Loose Flanges Manufacturer in Italy, Duplex 32205 Weld Neck Flanges A/ B Exporter in Yemen, Duplex 32205 Slip On Flange Supplier in Saudi Arabia, Duplex 2205 Blind Flange Stockist in UK, DIN 1.4462 RTJ Flanges Stockist in UK, DIN 1.4462 Reducing Flanges Manufacturer in Vietnam, ASME SA182 Duplex 2205 Socketweld Flange Stockist in UAE, ASTM A182 Duplex 2205 Forged Flanges Manufacturer in USA, UNS S32205 WNRF Flanges Stockist in Saudi Arabia, DIN 1.4462 Ring Type Joint Flanges Supplier in Jordan, 2205 Duplex Expander Flanges Stockist in Egypt.