Super Duplex 32750/ 32760 Flanges

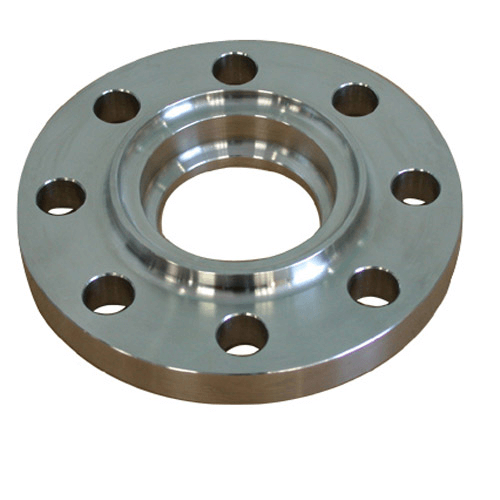

DIN 1.4410 Forging Facing Flanges, UNS S32760 Orifice Flanges, ASTM A182 Super Duplex 2507 Forged Flanges, ASTM A182 Super Duplex 2507 SORF Flanges, 2507 Super Duplex Flat Flanges.

About Super Duplex 32750/ 32760 Flanges

Flanges for super duplex 32750/32760 are constructed from premium raw materials. Large companies employ these flanges because of their rigidity. These flanges are frequently used in pumps, valves, and fittings and to link two pipes together. These flanges are constructed from premium materials. It contains beautiful substances like molybdenum and chromium. The primary dietary supplement for power and toughness is molybdenum. This element is enhanced with fantastic properties that make an alloy survive longer in harsh weather and high heat conditions. Excellent resistive power provided by molybdenum shields an alloy from rust, stress cracking, and corrosion fatigue.

Molybdenum and chromium are promising materials to make super duplex 32750 flanges, giving DIN 1.4410 exceptional qualities. These flanges are frequently used in large enterprises. The ability to withstand high heat pressure, dampness, erosion and oxidation gives these flanges an advantage. Due to these flanges’ extraordinarily high tensile and yield strengths, a wide range of industries can use them. These flanges have a 160000 PSI tensile strength and an 80000 PSI yield strength. A pipe’s blind flange can be bolted shut temporarily or welded shut permanently. Blind flanges are also utilized for cleaning in high-maintenance systems. To establish authentic connections, the UNS S32750 / S32760 are ideal for seamless pipes.

Features of Super Duplex S32750/S32760 Flanges :

They are employed in settings where gaskets, flange bolts, and ring joints are also present. There are many classifications, from Class 150 Super Duplex S32750/ S32760 Flanges to Class 2500. These indicate the flanges’ pressure capabilities. Industries can also use pressure numbers from PN6 to PN64 to describe the pressure capacity. The Super Duplex SS S32750/32760 Flange creates unique connections and contains an aperture for a fixture. Every form of flange has a distinct benefit. In this grade, the flanges’ sizes range from 12 to 48 inches, and their wall thicknesses vary.

Duplex steels have superior corrosion resistance in general. They have exceptional resistance to corrosion caused by pitting, stress-corrosion cracking, and corrosion-fatigue cracking. The duplex steel’s strength and hardness complement each other very well, and the steel has the best abrasion resistance. The steels can easily withstand abrasive stress and are ideal for all types of welding.

Flanges’ primary benefits are their ability to resist creep stress and rupture. It is more resistant and flexible. Flanges made of stainless steel S32750/32760 are distinct because they don’t produce carbide layers, preventing machine wear. Its high density and substantial elongation capacity boost its mechanical power. It is used in industrial settings for the production of aviation machinery, expansion joints, and waste treatment.

Super Duplex 32750 Square Flanges Exporter, 2507 Super Duplex Spades Ring Spacers Flanges Manufacturer, 2507 Super Duplex Flat Flanges Stockist.

Specification of Super Duplex 32750/ 32760 Flanges

| Specification | ASTM A182 / ASME SA182 |

| Dimension Standard | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| DIN Flanges | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673. |

| JIS Flanges | JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K |

| BS Flanges | BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H. |

Ready stock of Flanges available for Super Duplex 32750/ 32760 Flanges

Equivalent Grades of Super Duplex 32750/ 32760 Flanges

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex 2507 | 1.4410 | S32750 / S32760 |

Chemical Composition of Super Duplex 32750/ 32760 Flanges

| Element | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

| S32760 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

Mechanical Properties of Super Duplex 32750/ 32760 Flanges

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Super Duplex Steel S32750 / S32760 | 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000 , MPa – 800 | Psi – 80000 , MPa – 550 | 15 % |

Other Types of Flanges of Super Duplex 32750/ 32760 Flanges

Dimensions Standard Of Super Duplex 32750/ 32760 Flanges

| Nominal Size | Outside Diameter (OD) | Min. Thickness (T) | RF Dia. (R) | No. of Bolt Holes | Diameter of Holes | Bolt Circle (BC) | SO Bore ID (SB) | WN Bore ID (WB) | Dia. Hub Base (HB) | Dia. of Hub Top (HT) | SO LTH (SL) | WN LTH (WL) |

| 1⁄2 | 3.50 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.50 | 1.05 | 0.56 | 2.00 |

| 1 | 4.25 | 0.50 | 2.00 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.50 | 4 | 0.62 | 3.50 | 1.70 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5.00 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.90 | 0.81 | 2.38 |

| 2 | 6.00 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7.00 | 0.81 | 4.12 | 4 | 0.75 | 5.50 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.50 | 0.88 | 5.00 | 4 | 0.75 | 6.00 | 3.57 | 3.07 | 4.25 | 3.50 | 1.12 | 2.69 |

| 31⁄2 | 8.50 | 0.88 | 5.50 | 8 | 0.75 | 7.00 | 4.07 | 3.55 | 4.81 | 4.00 | 1.19 | 2.75 |

| 4 | 9.00 | 0.88 | 6.19 | 8 | 0.75 | 7.50 | 4.57 | 4.03 | 5.31 | 4.50 | 1.25 | 2.94 |

| 5 | 10.00 | 0.88 | 7.31 | 8 | 0.88 | 8.50 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11.00 | 0.94 | 8.50 | 8 | 0.88 | 9.50 | 6.72 | 6.07 | 7.56 | 6.63 | 1.50 | 3.44 |

| 8 | 13.50 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16.00 | 1.12 | 12.75 | 12 | 1.00 | 14.25 | 10.88 | 10.02 | 12.00 | 10.75 | 1.88 | 3.94 |

| 12 | 19.00 | 1.19 | 15.00 | 12 | 1.00 | 17.00 | 12.88 | 12.00 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21.00 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14.00 | 2.19 | 4.94 |

| 16 | 23.50 | 1.38 | 18.50 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18.00 | 16.00 | 2.44 | 4.94 |

| 18 | 25.00 | 1.50 | 21.00 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18.00 | 2.62 | 5.44 |

| 20 | 27.50 | 1.62 | 23.00 | 20 | 1.25 | 25.00 | 20.20 | 19.25 | 22.00 | 20.00 | 2.81 | 5.62 |

| 22 | 29.50 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22.00 | 3.07 | 5.82 |

| 24 | 32.00 | 1.81 | 27.25 | 20 | 1.38 | 29.50 | 24.25 | 23.25 | 26.12 | 24.00 | 3.19 | 5.94 |

Size Of Super Duplex 32750/ 32760 Flanges

| Nom. Pipe Size | o | T1 | R | x | No.2/Dia. of Holes | Bolt Circle Dia. | L21 | H | B23 | L | B | r | L34 | B3 | D |

| 1/2 | 3.50 | 0.44 | 1.38 | 1.19 | 4-0.62 | 2.38 | 1.88 | 0.84 | 0.62 | 0.62 | 0.88 | 0.12 | 0.62 | 0.90 | 0.38 |

| 3/4 | 3.88 | 0.50 | 1.69 | 1.50 | 4-0.62 | 2.75 | 2.06 | 1.05 | 0.82 | 0.62 | 1.09 | 0.12 | 0.62 | 1.11 | 0.44 |

| 1 | 4.25 | 0.56 | 2.00 | 1.94 | 4-0.62 | 3.12 | 2.19 | 1.32 | 1.05 | 0.69 | 1.36 | 0.12 | 0.69 | 1.38 | 0.50 |

| 1-1/4 | 4.62 | 0.62 | 2.50 | 2.31 | 4-0.62 | 3.50 | 2.25 | 1.66 | 1.38 | 0.81 | 1.70 | 0.19 | 0.81 | 1.72 | 0.56 |

| 1-1/2 | 5.00 | 0.68 | 2.88 | 2.56 | 4-0.62 | 3.88 | 2.44 | 1.90 | 1.61 | 0.88 | 1.95 | 0.25 | 0.88 | 1.97 | 0.62 |

| 2 | 6.00 | 0.75 | 3.62 | 3.06 | 4-0.75 | 4.75 | 2.50 | 2.38 | 2.07 | 1.00 | 2.44 | 0.31 | 1.00 | 2.46 | 0.69 |

| 2-1/2 | 7.00 | 0.88 | 4.12 | 3.56 | 4-0.75 | 5.50 | 2.75 | 2.88 | 2.47 | 1.12 | 2.94 | 0.31 | 1.12 | 2.97 | 0.75 |

| 3 | 7.50 | 0.94 | 5.00 | 4.25 | 4-0.75 | 6.00 | 2.75 | 3.50 | 3.07 | 1.19 | 3.57 | 0.38 | 1.19 | 3.60 | 0.81 |

| 3-1/2 | 8.50 | 0.94 | 5.50 | 4.81 | 8-0.75 | 7.00 | 2.81 | 4.00 | 3.55 | 1.25 | 4.07 | 0.38 | 1.25 | 4.10 | 0.88 |

| 4 | 9.00 | 0.94 | 6.19 | 5.31 | 8-0.75 | 7.50 | 3.00 | 4.50 | 4.03 | 1.31 | 4.57 | 0.44 | 1.31 | 4.60 | 0.94 |

| 5 | 10.00 | 0.94 | 7.31 | 6.44 | 8-0.88 | 8.50 | 3.50 | 5.56 | 5.05 | 1.44 | 5.66 | 0.44 | 1.44 | 5.69 | 0.94 |

| 6 | 11.00 | 1.00 | 8.50 | 7.56 | 8-0.88 | 9.50 | 3.50 | 6.63 | 6.07 | 1.56 | 6.72 | 0.50 | 1.56 | 6.75 | 1.06 |

| 8 | 13.50 | 1.12 | 10.62 | 9.69 | 8-0.88 | 11.75 | 4.00 | 8.63 | 7.98 | 1.75 | 8.72 | 0.50 | 1.75 | 8.75 | 1.25 |

| 10 | 16.00 | 1.19 | 12.75 | 12.00 | 12-1.00 | 14.25 | 4.00 | 10.75 | 10.02 | 1.94 | 10.88 | 0.50 | 1.94 | 10.92 | 1.31 |

| 12 | 19.00 | 1.25 | 15.00 | 14.38 | 12-1.00 | 17.00 | 4.50 | 12.75 | 12.00 | 2.19 | 12.88 | 0.50 | 2.19 | 12.92 | 1.56 |

| 14 | 21.00 | 1.38 | 16.25 | 15.75 | 12-1.12 | 18.75 | 5.00 | 14.00 | 13.25 | 2.25 | 14.14 | 0.50 | 3.12 | 14.18 | 1.63 |

| 16 | 23.50 | 1.44 | 18.50 | 18.00 | 16-1.12 | 21.25 | 5.00 | 16.00 | 15.25 | 2.50 | 16.16 | 0.50 | 3.44 | 16.19 | 1.75 |

| 18 | 25.00 | 1.56 | 21.00 | 19.88 | 16-1.25 | 22.75 | 5.50 | 18.00 | 17.25 | 2.69 | 18.18 | 0.50 | 3.81 | 18.20 | 1.94 |

| 20 | 27.50 | 1.69 | 23.00 | 22.00 | 20-1.25 | 25.00 | 5.69 | 20.00 | 19.25 | 2.88 | 20.20 | 0.50 | 4.06 | 20.25 | 2.13 |

| 22 | 29.50 | 1.81 | 25.25 | 24.25 | 20-1.38 | 27.25 | 5.88 | 22.00 | 21.25 | 3.13 | 22.22 | 0.50 | 4.25 | 22.25 | 2.38 |

| 24 | 32.00 | 1.88 | 27.25 | 26.12 | 20-1.38 | 29.50 | 6.00 | 24.00 | 23.25 | 3.25 | 24.25 | 0.50 | 4.38 | 24.25 | 2.50 |

Weight Chart Of Super Duplex 32750/ 32760 Flanges

| Standard Of Flanges | Class Of Flanges | Diameter Of Flanges | Diameter Of Bolt Circle | Bolts Number | Size Of Bolt | Bolt Hole Diameter |

| AS4087 Flanges | PN14 Flanges | 95 | 67 | 4 | M12 | 14 |

| AS 2129 Flange | Table C Flanges | 95 | 67 | 4 | 13 | 14 |

| Table D Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table E Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table F Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table H Flanges | 114 | 83 | 4 | 16 | 17 | |

| Table J Flanges | 114 | 83 | 4 | 16 | 17 | |

| ANSI B16.5 Flanges | ANSI 150 Flanges | 89 | 60 | 4 | 13 | 16 |

| ANSI 300 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 600 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 900 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ANSI 1500 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ISO 7005 (DIN) Flange | PN6 Flanges | 80 | 55 | 4 | M10 | 11 |

| PN10 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN16 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN20 Flanges | 90 | 60.5 | 4 | M14 | 16 | |

| PN25 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN40 Flanges | 95 | 65 | 4 | M12 | 14 |

Pressure Rating Of Super Duplex 32750/ 32760 Flanges

| Temp. ℃ | Pressure-ASME temperature rating for B16.47 by class, bar | |||||

| 75 | 150 | 300 | 400 | 600 | 900 | |

| -29 to 38 | 10.0 | 20.0 | 51.7 | 68.9 | 103.4 | 155.1 |

| 50 | 9.8 | 19.5 | 51.7 | 68.9 | 103.4 | 155.1 |

| 100 | 8.8 | 17.7 | 50.7 | 67.5 | 101.3 | 152.0 |

| 150 | 7.9 | 15.8 | 45.9 | 61.2 | 91.9 | 137.8 |

| 200 | 6.9 | 13.8 | 42.7 | 56.9 | 85.3 | 128.0 |

| 250 | 6.0 | 12.1 | 40.5 | 53.9 | 80.9 | 121.4 |

| 300 | 5.1 | 10.2 | 38.9 | 51.8 | 77.7 | 116.6 |

industrial use flanges for Super Duplex 32750/ 32760 Flanges

Price Of Super Duplex 32750/ 32760 Flanges

| Duplex and Super Duplex Forged Flanges | USD $10.20 - $35.50 / Piece (FOB Price) on request |

| Duplex and Super Duplex Blind Flanges | USD $10.20 - $35.50 / Piece (FOB Price) on request |

| Duplex and Super Duplex Slip On Flange | USD $10.20 - $35.50 / Piece (FOB Price) on request |

| Duplex and Super Duplex Socketweld Flanges | USD $10.20 - $35.50 / Piece (FOB Price) on request |

| Duplex and Super Duplex Long Weld Neck Flanges | USD $10.20 - $35.50 / Piece (FOB Price) on request |

Application Of Super Duplex 32750/ 32760 Flanges

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Super Duplex 32750/ 32760 Flanges

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

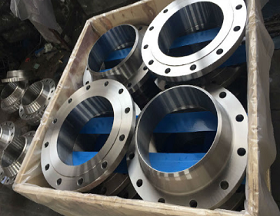

Packing Of Super Duplex 32750/ 32760 Flanges

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

Super Duplex 2507 Flanges Bolts Catalogue, UNS S32750 WNRF Flanges Price List In India, 32750 Super Duplex Weldo / Nipo Flanges At Factory Price, ASME SA182 Super Duplex 32760 Spectacle Blind Flanges Weight Chart, 2507 Super Duplex Spades Ring Spacers Flanges Price Per Kg, DIN 1.4410 Threaded Flanges Catalogue, DIN 1.4410 RTJ Flanges Catalogue, 2507 Super Duplex Expander Flanges Weight Calculator, Super Duplex 2507 Longweld Neck Flange At Factory Price, ASME SA182 Super Duplex 2507 Socketweld Flange At Factory Price, UNS S32750 Loose Flanges Price List In India, DIN 1.4410 Ring Type Joint Flanges Catalogue.

2507 Super Duplex Expander Flanges Stockist in Kerla, UNS S32760 Orifice Flanges Stockist in Bangalore, Super Duplex 2507 Blind Flange Stockist in Pimpri-Chinchwad, DIN 1.4410 Reducing Flanges Manufacturer in Vadodara, DIN 1.4410 RTJ Flanges Stockist in Gujarat, DIN 1.4410 Threaded Flanges Stockist in Ahmedabad, UNS S32750 Loose Flanges Manufacturer in Daman, DIN 1.4410 Ring Type Joint Flanges Supplier in Tamilnadu, ASTM A182 Super Duplex 2507 Forged Flanges Manufacturer in Bengaluru, UNS S32760 Lap Joint Flanges Manufacturer in Mumbai, Super Duplex 32760 SWRF Flanges Manufacturer in Lucknow.

UNS S32760 Screwed Flanges Stockist in Libya, 32750 Super Duplex Weldo / Nipo Flanges Exporter in Indonesia, 2507 Super Duplex Spades Ring Spacers Flanges Manufacturer in Tunisia, DIN 1.4410 RTJ Flanges Stockist in UK, UNS S32750 Loose Flanges Manufacturer in Italy, DIN 1.4410 Forging Facing Flanges Supplier in Algeria, 2507 Super Duplex Expander Flanges Stockist in Egypt, Super Duplex 2507 Longweld Neck Flange Supplier in Qatar, UNS S32760 Orifice Flanges Exporter in South Africa, Super Duplex 32750 Square Flanges Exporter in Iran, UNS S32750 WNRF Flanges Stockist in Saudi Arabia.