Stainless Steel 904L Forged fitting

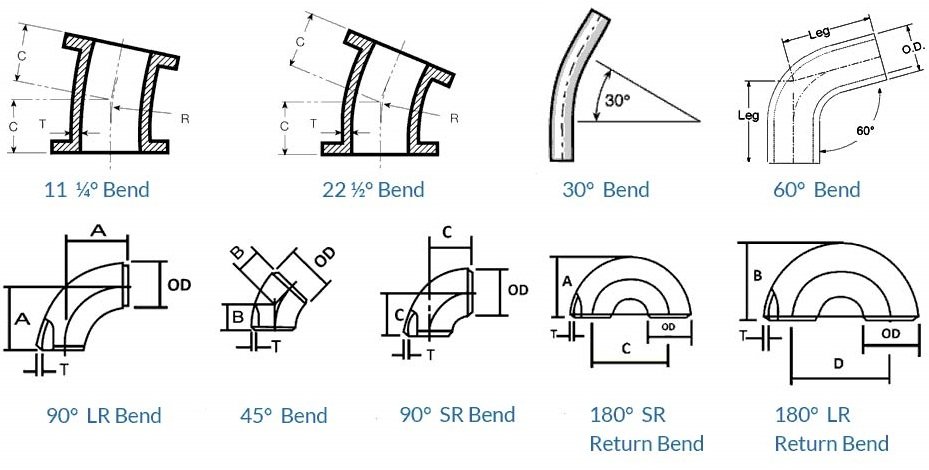

ASTM A182 SS 904L Threaded Hex Nipple, SS 904L Threaded 45 Lateral Tee, DIN 1.4539 Round Plug, UNS N08904 Threaded Plug, DIN 1.4539 Threaded Bush, DIN 1.4539 Threaded Street Elbow, Stainless Steel 904L 90 Degree Elbow.

About Stainless Steel 904L Forged fitting

Nissan Steel specializes in wholesale selling and supplying SS 904L Forged Socket Weld Fittings. We offer these fittings to our customers at the most competitive prices. Compared to grades 304L and 310L, which do not contain molybdenum, the Stainless Steel 904L Forged Socket Weld Elbow has lower resistance to nitric acid. However, the Stainless Steel 904L Forged Socket Weld Tee offers good oxidation resistance, allowing it to be used in applications where most standard fusion and resistance techniques are applicable. The Stainless Steel 904L Forged Socket Weld Cap loses its ability to maintain its structural integrity at high temperatures, especially above 400 degrees Celsius.

Stainless Steel 904L Forged Socket Weld Coupling can undergo solution heat treatment at temperatures between 1090 degrees Celsius to 1175 degrees Celsius, followed by quick cooling. This thermal treatment is excellent for hardening these grades. After cold working, treating the Stainless Steel 904L Socket Weld Fittings is necessary to obtain optimal stress corrosion cracking resistance in critical situations.

Welding of Stainless Steel 904L Socket Weld Union can be performed using any standard technique, and pre- and post-weld heat treatments are unnecessary. It is also possible for a Stainless Steel 904L Socket Weld Fittings to experience hot cracking in a confined weldment. Additionally, the plug can be easily bent to a small radius after it has cooled.

After any hot work is completed, the Stainless Steel 904L Socket Weld Lateral Tee must undergo full annealing to regain maximum ductility and resistance to corrosion. Nissan Steel’s SS 904L Forged Socket Weld Fittings offer excellent quality and durability for various applications.

UNS N08904 Reducing Cross Stockist, SS 904L Nipple Branch Outlet Manufacturer, SS 904L Threaded 45 Lateral Tee Exporter, SS 904L Sockolet Exporter, UNS N08904 Threaded Plug Manufacturer, 904L SS Union Exporter.

Specification of Stainless Steel 904L Forged fitting

| Specification | ASTM A182 / ASME SA182 |

| Dimension Standard | ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799 |

| Size | 1/8" NB to 4" NB |

| Type | Socketweld Fittings, Screwed-Threaded Fittings |

| Pressure-Temperature Class | Threaded End - 2000 /3000/ 6000 LBS. Socket-weld End - 3000 / 6000/ 9000 LBS. |

Ready stock of available for Stainless Steel 904L Forged fitting

Equivalent Grades of Stainless Steel 904L Forged fitting

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

Chemical Composition of Stainless Steel 904L Forged fitting

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

| SS 904L | 0.020 max | 2.00 max | 1.00 max | 0.040 max | 0.030 max | 19.00 – 23.00 | 4.00 – 5.00 max | 23.00 – 28.00 | 1.00 – 2.00 |

Mechanical Properties of Stainless Steel 904L Forged fitting

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.95 g/cm3 | 1350 °C (2460 °F) | Psi – 71000 , MPa – 490 | Psi – 32000 , MPa – 220 | 35 % |

Other Types of Stainless Steel 904L Forged fitting

Dimensions Standard Of Stainless Steel 904L Forged fitting

| ASME b16.9 Fittings Normal Pipe Size | ANSI b16 9 Pipe Fitting O D Y | Wall Thickness T (Pipe Elbow Sch.) | LR 45 Deg Elbows Centre to Face B | SR 45 Deg Elbows Weight | LR 90 Deg Elbows Centre to Face A | LR 90 Deg Elbows Weight In Below | SR 90 Deg Elbows Centre to Face A | SR 90 Deg Elbows Weight In Below | ||

| mm | inch | mm | mm | Schedule | mm | kg | mm | kg | mm | kg |

| 15 | 1/2” | 21.3 | 2.78 | STD | 15.9 | 0.04 | 38.1 | 0.08 | – | – |

| 3.73 | X.S | 15.9 | 0.05 | 38.1 | 0.10 | – | – | |||

| 20 | 3/4” | 26.7 | 2.87 | STD | 11.1 | 0.04 | 28.6 | 0.08 | – | – |

| 3.91 | X.S | 11.1 | 0.05 | 28.6 | 0.11 | – | – | |||

| 25 | 1” | 33.4 | 3.38 | STD | 22.2 | 0.09 | 38.1 | 0.15 | 25.4 | 0.11 |

| 4.55 | X.S | 22.2 | 0.11 | 38.1 | 0.19 | 25.4 | 0.14 | |||

| 32 | 11/4” | 42.2 | 3.56 | STD | 25.4 | 0.14 | 47.6 | 0.28 | 31.75 | 0.18 |

| 4.85 | X.S | 25.4 | 0.2 | 47.6 | 0.39 | 31.75 | 0.24 | |||

| 40 | 11/2” | 48.3 | 3.68 | STD | 28.6 | 0.2 | 57.1 | 0.4 | 38.1 | 0.26 |

| 5.08 | X.S | 28.6 | 0.25 | 57.1 | 0.5 | 38.1 | 0.35 | |||

| 50 | 2” | 60.3 | 3.91 | STD | 34.9 | 0.36 | 76.2 | 0.72 | 50.8 | 0.5 |

| 5.54 | X.S | 34.9 | 0.5 | 76.2 | 1.0 | 50.8 | 0.68 | |||

| 65 | 21/2” | 73.0 | 5.16 | STD | 44.4 | 0.73 | 95.2 | 1.46 | 63.5 | 0.95 |

| 7.01 | X.S | 44.4 | 0.91 | 95.2 | 1.82 | 63.5 | 1.27 | |||

| 80 | 3” | 88.9 | 5.49 | STD | 50.8 | 1.1 | 114.3 | 2.18 | 76.2 | 1.45 |

| 7.62 | X.S | 50.8 | 1.45 | 114.3 | 2.86 | 76.2 | 1.95 | |||

| 100 | 4” | 114.3 | 6.02 | STD | 63.5 | 2.1 | 152.4 | 4.2 | 101.6 | 2.8 |

| 8.56 | X.S | 63.5 | 2.9 | 152.4 | 5.7 | 101.6 | 3.9 | |||

| 125 | 5” | 141.3 | 6.65 | STD | 79.4 | 3.4 | 190.0 | 6.8 | 127.0 | 4.8 |

| 9.5 | X.S | 79.4 | 5.0 | 190.0 | 10.0 | 127.0 | 6.5 | |||

| 150 | 6” | 168.3 | 7.11 | STD | 95.2 | 5.1 | 229.0 | 10.1 | 152.4 | 6.8 |

| 10.97 | X.S | 95.2 | 7.7 | 229.0 | 15.3 | 152.4 | 10.2 | |||

| 200 | 8” | 219.1 | 8.18 | STD | 127.0 | 10.2 | 305.0 | 20.4 | 203.0 | 13.6 |

| 12.7 | X.S | 127.0 | 15.5 | 305.0 | 30.9 | 203.0 | 20.9 | |||

| 250 | 10” | 273.9 | 9.27 | STD | 159.0 | 18.1 | 381.0 | 36.1 | 254.0 | 24.1 |

| 12.7 | X.S | 159.0 | 24.4 | 381.0 | 48.8 | 254.0 | 32.5 | |||

| 300 | 12” | 323.9 | 9.52 | STD | 190.0 | 26.6 | 457.0 | 53.1 | 305.0 | 35.4 |

| 12.7 | X.S | 190.0 | 35.0 | 457.0 | 70.0 | 305.0 | 46.7 | |||

| 350 | 14” | 355.6 | 9.52 | STD | 222.0 | 34.1 | 533.0 | 68.1 | 356.0 | 45.4 |

| 12.7 | X.S | 222.0 | 45.0 | 533.0 | 90.0 | 356.0 | 60.0 | |||

| 400 | 16” | 406.4 | 9.52 | STD | 254.0 | 45.0 | 610.0 | 89.3 | 406.0 | 59.5 |

| 12.7 | X.S | 254.0 | 59.0 | 610.0 | 118.0 | 406.0 | 78.7 | |||

| 450 | 18” | 457.0 | 9.52 | STD | 286.0 | 56.5 | 686.0 | 113.0 | 457.0 | 75.6 |

| 12.7 | X.S | 286.0 | 75.0 | 686.0 | 150.0 | 457.0 | 100.0 | |||

| 500 | 20” | 508.0 | 9.52 | STD | 318.0 | 85.0 | 762.0 | 140.0 | 508.0 | 93.5 |

| 12.7 | X.S | 318.0 | 112.5 | 762.0 | 186.0 | 508.0 | 124.0 | |||

| 600 | 24” | 610.00 | 9.52 | STD | 381.0 | 101.5 | 914.0 | 203.0 | 610.0 | 135.0 |

| 12.7 | X.S | 381.0 | 134.5 | 914.0 | 269.0 | 610.0 | 179.0 | |||

Size Of Stainless Steel 904L Forged fitting

| NPS (inch) | Pipe Schedule. | OD (inch) | Wall Thick. (in) | Temperature | ||||

| 100 Fitting | 200 Fitting | 300 Fitting | 400 Fitting | 500 Fitting | ||||

| Allowable Stress | ||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | ||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 |

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | |

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | |

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 |

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | |

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | |

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 |

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | |

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | |

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 |

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | |

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | |

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 |

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | |

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | |

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 |

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | |

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | |

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 |

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | |

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | |

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 |

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | |

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | |

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 |

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | |

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | |

Weight Chart Of Stainless Steel 904L Forged fitting

| Normal Pipe Sizes | A | B | QTY | Weight In KG |

| ¼ | 0.81 | 0.88 | 160 | 0.20 |

| ⁄ | 0.97 | 1.00 | 130 | 0.26 |

| ½ | 1.12 | 1.31 | 100 | 0.57 |

| ¾ | 1.31 | 1.5 | 75 | 0.71 |

| 1 | 1.5 | 1.81 | 40 | 1.08 |

| 1 ¼ | 1.75 | 2.19 | 25 | 1.68 |

| 1 ½ | 2.00 | 2.44 | 18 | 2.38 |

| 2 | 2.38 | 2.97 | 10 | 3.55 |

| 2 ½ | 3.00 | 3.62 | 4 | 6.22 |

| 3 | 3.38 | 4.31 | 2 | 10.36 |

| 4 | 4.19 | 5.75 | 1 | 23.91 |

Pressure Rating Of Stainless Steel 904L Forged fitting

| Pressure-Temperature | |||||

| Temperature | Class | ||||

| 150 | 300 | ||||

| 1/4 - 1 inch. | 1 1/4 - 2 inch. | 2 1/2 - 3 inch. | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | - | 935 | 750 | 560 |

| 450 | 232 | - | 725 | 600 | 475 |

| 500 | 260 | - | 510 | 450 | 385 |

| 550 | 288 | - | 300 | 300 | 300 |

industrial use fitting for Stainless Steel 904L Forged fitting

Price Of Stainless Steel 904L Forged fitting

| Stainless Steel Elbow | USD $2.06 - $10.07 / Piece (FOB Price) on request |

| Stainless Steel Equal Tee | USD $2.06 - $10.07 / Piece (FOB Price) on request |

| Stainless Steel Reducing Tee | USD $2.06 - $10.07 / Piece (FOB Price) on request |

| Stainless Steel Cross | USD $2.06 - $10.07 / Piece (FOB Price) on request |

| Stainless Steel Cap | USD $2.06 - $10.07 / Piece (FOB Price) on request |

Application Of Stainless Steel 904L Forged fitting

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Stainless Steel 904L Forged fitting

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

Packing Of Stainless Steel 904L Forged fitting

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

Stainless Steel Forged Fittings

- Stainless Steel 304/ 304L/ 304H Forged Fittings

- Stainless Steel 309 Forged Fittings

- Stainless Steel 310/ 310S Forged Fittings

- Stainless Steel 316/ 316L/ 316Ti Forged Fittings

- Stainless Steel 321 Forged Fittings

- Stainless Steel 347/ 347H Forged Fittings

- Stainless Steel 904L Forged Fittings

- Stainless Steel 15-5 PH Forged Fittings

- Stainless Steel 17-4 PH Forged Fittings