Nickel 200/ 201 Flanges

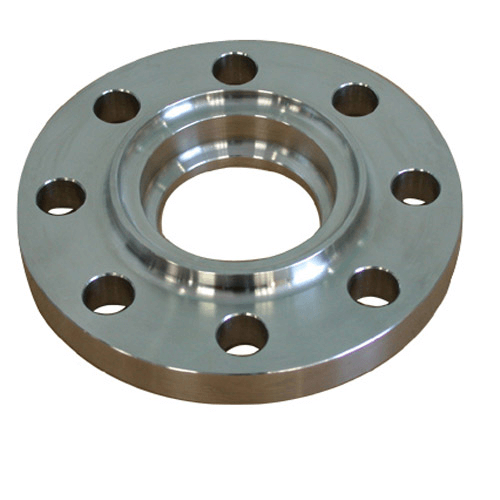

ASME SB564 Nickel 200 Socketweld Flange, Nickel Alloy 201 Groove & Tongue Flanges, ASTM B564 Nickel 200 Forged Flanges, UNS N02200 Loose Flanges, 201 Nickel Weldo / Nipo Flanges, 200 Nickel Flat Flanges.

About Nickel 200/ 201 Flanges

Since nickel is their primary base metal and comprises around 99.6% of Nickel 200 and Nickel 201, they are both commercially pure nickel alloys. Chemically, Nickel 201 is the Low-Carbon Variant, With Its Concentration Equating To 0.02 Max of the Total Composition. Nickel 200 Is the High-Carbon Version. Relative to Nickel 200, where the carbon content of the whole alloy is about 0.15 at most. One thing that sets nickel 201 apart from nickel 200 is that the metal is more suited than the latter for applications that need exposure to situations where temperatures can exceed 600 F.

Heat transfer processes, capacitors, petrochemicals, specialized chemicals, the automotive industry, the chemical industry, the pulp and paper industry, etc., are some industries where UNS N02200 / N02201 Flanges are employed. Nickel 200/201 Flanges undergo a rigorous quality check to ensure that only high-quality products are shipped. Nickel 200/201 Flanges have a lot of beneficial characteristics to offer, which are made possible by the efficient use of 100% pure Nickel 200/201 alloy in their construction. The qualities include resistance to caustic alkalis, reducing chemicals, electrical conductivity, heat resistance, excellent tensile characteristics, and resistance to sulfuric and hydrochloric acid.

Properties of Nickel 200/201 Flanges :

- The UNS N02200 Flange provides exceptional resistance to numerous situations involving corrosive media and outstanding mechanical qualities.

- The softened flange is ductile, weldable, and has a low hardness. As a result, heating nickel makes the material simple to work with.

- ANSI Nickel 201 Flange Standards may be cold-worked to pretty high levels of strength while retaining their flexibility while having a low work-hardening rate.

- The Nickel 220 Flanges are recovered from cold working by being annealed. The temperatures between which this procedure is performed may range from 1100°F to 1700°F.

- It should be noted that long-term exposure of Nickel 200 to temperatures between 800 F and 1200 F may cause graphite precipitation.

- Nickel 201 must be employed in these applications to stop graphite precipitation. In general, the annealed alloy tends to generate lengthy, stringy chips. In contrast, material that has undergone a certain amount of hard work tends to be much easier on the machine.

- While it is possible to weld both alloys, DIN 2.4066 and DIN 2.4068, using standard shop methods, Oxy Acetylene welding should not be utilized on Nickel 201 owing to the risk of carbon collection in the alloy.

- Both grades, Nickel 201 and Nickel 200 Flange Dimensions, may be forged at temperatures between 2200- and 1600 degrees Fahrenheit. Although light forging can be done at temperatures lower than 1200oF, this is typically done to enhance the alloy’s mechanical characteristics.

200 Nickel Flat Flanges Stockist, UNS N02200 Loose Flanges Manufacturer, ASTM B564 Nickel 200 Forged Flanges Manufacturer.

Specification of Nickel 200/ 201 Flanges

| Specification | ASTM B564 / ASME SB564 |

| Dimension Standard | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| DIN Flanges | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673. |

| JIS Flanges | JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K |

| BS Flanges | BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H. |

Ready stock of Flanges available for Nickel 200/ 201 Flanges

Equivalent Grades of Nickel 200/ 201 Flanges

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Nickel 200 | 2.4066 | N02200 | NW 2200 | NA 11 | НП-2 | N-100M | Ni 99.2 |

| Nickel 201 | 2.4068 | N02201 | NW 2201 | NA 12 | НП-2 | – | LC-Ni 99 |

Chemical Composition of Nickel 200/ 201 Flanges

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| Nickel 201 | 0.02 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Mechanical Properties of Nickel 200/ 201 Flanges

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Nickel 200 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

| Nickel 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

Other Types of Flanges of Nickel 200/ 201 Flanges

Dimensions Standard Of Nickel 200/ 201 Flanges

| Nominal Size | Outside Diameter (OD) | Min. Thickness (T) | RF Dia. (R) | No. of Bolt Holes | Diameter of Holes | Bolt Circle (BC) | SO Bore ID (SB) | WN Bore ID (WB) | Dia. Hub Base (HB) | Dia. of Hub Top (HT) | SO LTH (SL) | WN LTH (WL) |

| 1⁄2 | 3.50 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.50 | 1.05 | 0.56 | 2.00 |

| 1 | 4.25 | 0.50 | 2.00 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.50 | 4 | 0.62 | 3.50 | 1.70 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5.00 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.90 | 0.81 | 2.38 |

| 2 | 6.00 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7.00 | 0.81 | 4.12 | 4 | 0.75 | 5.50 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.50 | 0.88 | 5.00 | 4 | 0.75 | 6.00 | 3.57 | 3.07 | 4.25 | 3.50 | 1.12 | 2.69 |

| 31⁄2 | 8.50 | 0.88 | 5.50 | 8 | 0.75 | 7.00 | 4.07 | 3.55 | 4.81 | 4.00 | 1.19 | 2.75 |

| 4 | 9.00 | 0.88 | 6.19 | 8 | 0.75 | 7.50 | 4.57 | 4.03 | 5.31 | 4.50 | 1.25 | 2.94 |

| 5 | 10.00 | 0.88 | 7.31 | 8 | 0.88 | 8.50 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11.00 | 0.94 | 8.50 | 8 | 0.88 | 9.50 | 6.72 | 6.07 | 7.56 | 6.63 | 1.50 | 3.44 |

| 8 | 13.50 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16.00 | 1.12 | 12.75 | 12 | 1.00 | 14.25 | 10.88 | 10.02 | 12.00 | 10.75 | 1.88 | 3.94 |

| 12 | 19.00 | 1.19 | 15.00 | 12 | 1.00 | 17.00 | 12.88 | 12.00 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21.00 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14.00 | 2.19 | 4.94 |

| 16 | 23.50 | 1.38 | 18.50 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18.00 | 16.00 | 2.44 | 4.94 |

| 18 | 25.00 | 1.50 | 21.00 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18.00 | 2.62 | 5.44 |

| 20 | 27.50 | 1.62 | 23.00 | 20 | 1.25 | 25.00 | 20.20 | 19.25 | 22.00 | 20.00 | 2.81 | 5.62 |

| 22 | 29.50 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22.00 | 3.07 | 5.82 |

| 24 | 32.00 | 1.81 | 27.25 | 20 | 1.38 | 29.50 | 24.25 | 23.25 | 26.12 | 24.00 | 3.19 | 5.94 |

Size Of Nickel 200/ 201 Flanges

| Nom. Pipe Size | o | T1 | R | x | No.2/Dia. of Holes | Bolt Circle Dia. | L21 | H | B23 | L | B | r | L34 | B3 | D |

| 1/2 | 3.50 | 0.44 | 1.38 | 1.19 | 4-0.62 | 2.38 | 1.88 | 0.84 | 0.62 | 0.62 | 0.88 | 0.12 | 0.62 | 0.90 | 0.38 |

| 3/4 | 3.88 | 0.50 | 1.69 | 1.50 | 4-0.62 | 2.75 | 2.06 | 1.05 | 0.82 | 0.62 | 1.09 | 0.12 | 0.62 | 1.11 | 0.44 |

| 1 | 4.25 | 0.56 | 2.00 | 1.94 | 4-0.62 | 3.12 | 2.19 | 1.32 | 1.05 | 0.69 | 1.36 | 0.12 | 0.69 | 1.38 | 0.50 |

| 1-1/4 | 4.62 | 0.62 | 2.50 | 2.31 | 4-0.62 | 3.50 | 2.25 | 1.66 | 1.38 | 0.81 | 1.70 | 0.19 | 0.81 | 1.72 | 0.56 |

| 1-1/2 | 5.00 | 0.68 | 2.88 | 2.56 | 4-0.62 | 3.88 | 2.44 | 1.90 | 1.61 | 0.88 | 1.95 | 0.25 | 0.88 | 1.97 | 0.62 |

| 2 | 6.00 | 0.75 | 3.62 | 3.06 | 4-0.75 | 4.75 | 2.50 | 2.38 | 2.07 | 1.00 | 2.44 | 0.31 | 1.00 | 2.46 | 0.69 |

| 2-1/2 | 7.00 | 0.88 | 4.12 | 3.56 | 4-0.75 | 5.50 | 2.75 | 2.88 | 2.47 | 1.12 | 2.94 | 0.31 | 1.12 | 2.97 | 0.75 |

| 3 | 7.50 | 0.94 | 5.00 | 4.25 | 4-0.75 | 6.00 | 2.75 | 3.50 | 3.07 | 1.19 | 3.57 | 0.38 | 1.19 | 3.60 | 0.81 |

| 3-1/2 | 8.50 | 0.94 | 5.50 | 4.81 | 8-0.75 | 7.00 | 2.81 | 4.00 | 3.55 | 1.25 | 4.07 | 0.38 | 1.25 | 4.10 | 0.88 |

| 4 | 9.00 | 0.94 | 6.19 | 5.31 | 8-0.75 | 7.50 | 3.00 | 4.50 | 4.03 | 1.31 | 4.57 | 0.44 | 1.31 | 4.60 | 0.94 |

| 5 | 10.00 | 0.94 | 7.31 | 6.44 | 8-0.88 | 8.50 | 3.50 | 5.56 | 5.05 | 1.44 | 5.66 | 0.44 | 1.44 | 5.69 | 0.94 |

| 6 | 11.00 | 1.00 | 8.50 | 7.56 | 8-0.88 | 9.50 | 3.50 | 6.63 | 6.07 | 1.56 | 6.72 | 0.50 | 1.56 | 6.75 | 1.06 |

| 8 | 13.50 | 1.12 | 10.62 | 9.69 | 8-0.88 | 11.75 | 4.00 | 8.63 | 7.98 | 1.75 | 8.72 | 0.50 | 1.75 | 8.75 | 1.25 |

| 10 | 16.00 | 1.19 | 12.75 | 12.00 | 12-1.00 | 14.25 | 4.00 | 10.75 | 10.02 | 1.94 | 10.88 | 0.50 | 1.94 | 10.92 | 1.31 |

| 12 | 19.00 | 1.25 | 15.00 | 14.38 | 12-1.00 | 17.00 | 4.50 | 12.75 | 12.00 | 2.19 | 12.88 | 0.50 | 2.19 | 12.92 | 1.56 |

| 14 | 21.00 | 1.38 | 16.25 | 15.75 | 12-1.12 | 18.75 | 5.00 | 14.00 | 13.25 | 2.25 | 14.14 | 0.50 | 3.12 | 14.18 | 1.63 |

| 16 | 23.50 | 1.44 | 18.50 | 18.00 | 16-1.12 | 21.25 | 5.00 | 16.00 | 15.25 | 2.50 | 16.16 | 0.50 | 3.44 | 16.19 | 1.75 |

| 18 | 25.00 | 1.56 | 21.00 | 19.88 | 16-1.25 | 22.75 | 5.50 | 18.00 | 17.25 | 2.69 | 18.18 | 0.50 | 3.81 | 18.20 | 1.94 |

| 20 | 27.50 | 1.69 | 23.00 | 22.00 | 20-1.25 | 25.00 | 5.69 | 20.00 | 19.25 | 2.88 | 20.20 | 0.50 | 4.06 | 20.25 | 2.13 |

| 22 | 29.50 | 1.81 | 25.25 | 24.25 | 20-1.38 | 27.25 | 5.88 | 22.00 | 21.25 | 3.13 | 22.22 | 0.50 | 4.25 | 22.25 | 2.38 |

| 24 | 32.00 | 1.88 | 27.25 | 26.12 | 20-1.38 | 29.50 | 6.00 | 24.00 | 23.25 | 3.25 | 24.25 | 0.50 | 4.38 | 24.25 | 2.50 |

Weight Chart Of Nickel 200/ 201 Flanges

| Standard Of Flanges | Class Of Flanges | Diameter Of Flanges | Diameter Of Bolt Circle | Bolts Number | Size Of Bolt | Bolt Hole Diameter |

| AS4087 Flanges | PN14 Flanges | 95 | 67 | 4 | M12 | 14 |

| AS 2129 Flange | Table C Flanges | 95 | 67 | 4 | 13 | 14 |

| Table D Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table E Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table F Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table H Flanges | 114 | 83 | 4 | 16 | 17 | |

| Table J Flanges | 114 | 83 | 4 | 16 | 17 | |

| ANSI B16.5 Flanges | ANSI 150 Flanges | 89 | 60 | 4 | 13 | 16 |

| ANSI 300 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 600 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 900 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ANSI 1500 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ISO 7005 (DIN) Flange | PN6 Flanges | 80 | 55 | 4 | M10 | 11 |

| PN10 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN16 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN20 Flanges | 90 | 60.5 | 4 | M14 | 16 | |

| PN25 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN40 Flanges | 95 | 65 | 4 | M12 | 14 |

Pressure Rating Of Nickel 200/ 201 Flanges

| Temp. ℃ | Pressure-ASME temperature rating for B16.47 by class, bar | |||||

| 75 | 150 | 300 | 400 | 600 | 900 | |

| -29 to 38 | 10.0 | 20.0 | 51.7 | 68.9 | 103.4 | 155.1 |

| 50 | 9.8 | 19.5 | 51.7 | 68.9 | 103.4 | 155.1 |

| 100 | 8.8 | 17.7 | 50.7 | 67.5 | 101.3 | 152.0 |

| 150 | 7.9 | 15.8 | 45.9 | 61.2 | 91.9 | 137.8 |

| 200 | 6.9 | 13.8 | 42.7 | 56.9 | 85.3 | 128.0 |

| 250 | 6.0 | 12.1 | 40.5 | 53.9 | 80.9 | 121.4 |

| 300 | 5.1 | 10.2 | 38.9 | 51.8 | 77.7 | 116.6 |

industrial use flanges for Nickel 200/ 201 Flanges

Price Of Nickel 200/ 201 Flanges

| High Nickel Alloys Forged Flanges | USD $8.10 - $20.20 / Piece (FOB Price) on request |

| High Nickel Alloys Blind Flanges | USD $8.10 - $20.20 / Piece (FOB Price) on request |

| High Nickel Alloys Slip On Flange | USD $8.10 - $20.20 / Piece (FOB Price) on request |

| High Nickel Alloys Socketweld Flanges | USD $8.10 - $20.20 / Piece (FOB Price) on request |

| High Nickel Alloys Long Weld Neck Flanges | USD $8.10 - $20.20 / Piece (FOB Price) on request |

Application Of Nickel 200/ 201 Flanges

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Nickel 200/ 201 Flanges

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

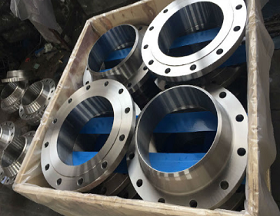

Packing Of Nickel 200/ 201 Flanges

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

Nickel 201 SWRF Flanges Price Per Kg, 200 Nickel Expander Flanges Weight Calculator, 200 Nickel Spades Ring Spacers Flanges Price Per Kg, Nickel Alloy 201 Flanges Bolts Catalogue, Nickel Alloy 200 Longweld Neck Flange At Factory Price, Nickel Alloy 201 Blind Flange Price List, ASTM B564 Nickel 200 Forged Flanges Weight Chart, UNS N02200 Screwed Flanges Weight Calculator.

201 Nickel Weldo / Nipo Flanges Supplier in Hyderabad, Nickel Alloy 200 Weld Neck Flanges A/ B Exporter in Punjab, 200 Nickel Alloy Weldneck Flanges Supplier in Hyderabad, Nickel Alloy 201 Flanges Bolts Exporter in Patna, DIN 2.4066 Forging Facing Flanges Supplier in Kolkata, Nickel 201 SWRF Flanges Manufacturer in Lucknow, DIN 2.4068 Ring Type Joint Flanges Supplier in Tamilnadu, 200 Nickel Flat Flanges Stockist in Bharuch.

ASME SB564 Nickel 200 Socketweld Flange Stockist in UAE, ASTM B564 Nickel 200 Forged Flanges Manufacturer in USA, Nickel Alloy 200 Weld Neck Flanges A/ B Exporter in Yemen, 201 Nickel Weldo / Nipo Flanges Exporter in Indonesia, DIN 2.4066 Forging Facing Flanges Supplier in Algeria, Nickel Alloy 201 Square Flanges Exporter in Iran, Nickel Alloy 200 Longweld Neck Flange Supplier in Qatar.