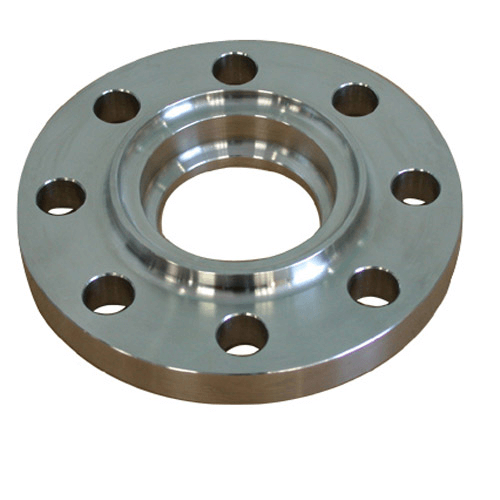

Inconel 600/ 601/ 625 Flanges

625 Inconel Spades Ring Spacers Flanges, UNS N06625 Loose Flanges, DIN 2.4816 Threaded Flanges, DIN 2.4851 Reducing Flanges, Inconel 625 Slip On Flange, DIN 2.4816 Ring Type Joint Flanges.

About Inconel 600/ 601/ 625 Flanges

Inconel alloy, a blend of Nickel and Chromium, gives UNS N06600/N06601/N06625 flanges their distinctive appearance. Inconel is the most used alloy for making various flanges since it has several good qualities. It is durable in an open atmosphere and resistant to oxidation. Because of its highly high-temperature resistance, it can endure the high temperatures used in many manufacturing and processing sectors. Corrosion resistance is another quality that makes it valuable. It is frequently used in hardening and chloride-exposed environments and can withstand hard-exposed environmental circumstances. Due to their high durability and corrosive qualities, Inconel 600/601/625/718 flanges are durable in ammonia and nitrogen-exposed environments. In Inconel 600 Flanges, a higher Chromium concentration prevents high-temperature cracks, a quality essential in the shipbuilding and steel construction industries.

Properties of Inconel 600/601/625 Flanges:

- Inconel 600 flanges are ideal for the iron and soldering industries since they are non-magnetic and conducive to welding.

- It is employed in the production of EDC cracking tubes and thermocouple sheaths.

- Due to its high-pressure sustainability capability, Inconel 600 flanges are utilized in pressurized water reactors to regulate steam generator plates.

- The flanges have several beneficial qualities, including high tensile strength, rugged design, anti-corrosive, flexibility, and durability.

- Additionally, it possesses qualities like oxidation resistance, pitting resistance, stress protection against corrosion, general corrosion resistance, and crevice corrosion resistance.

- DIN 2.4816, 2.4851 and 2.4856 Flanges also have a lot of good qualities that, depending on their applicability, may be used for various tasks.

- Among the best qualities are the best qualities of excellent tensile strength, exceptional dimensional precision, outstanding good surface finish, rugged construction, flexibility resistant to corrosion, extended service lives, affordable maintenance costs, and, most significantly, high toughness.

Uses of Inconel 600/601/625 Flanges:

Steam line pipe, maritime, chemical processing, nuclear power generation, and aerospace are the key industries that employ Inconel 625 flanges. These come in various sizes and forms, such as pipe flanges, rings, slip-on flanges, socket weld flanges, etc.

In the petrochemical, power generating, gas processing, manufacturing of chemical and pharmaceutical equipment, heat exchangers, and condenser sectors, Inconel 600 flanges are employed. These flanges are unusable for any industry. Inconel flanges are a necessary component of the production and processing processes. Additionally, it is utilized in nuclear weapons to regulate numerous tubes and containers. Roller hearths, retorts, muffles, and other items are further used for Inconel 600 flanges.

Industries, including chemical processing, aircraft, the heat treatment sector, power generation, radiant tubes, etc., require Inconel 601 flanges. Additionally, Inconel 601 flanges are utilized in the petrochemical, petroleum and natural gas, pulp and paper, textile, and other sectors.

600 Inconel Flat Flanges Stockist, Inconel Alloy 601 Weld Neck Flanges A/ B Exporter, ASTM B564 Inconel 600 Spectacle Blind Flanges Exporter.

Specification of Inconel 600/ 601/ 625 Flanges

| Specification | ASTM B564 / ASME SB564 |

| Dimension Standard | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| DIN Flanges | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673. |

| JIS Flanges | JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K |

| BS Flanges | BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H. |

Ready stock of Flanges available for Inconel 600/ 601/ 625 Flanges

Equivalent Grades of Inconel 600/ 601/ 625 Flanges

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | GOST | OR | BS | JIS | EN |

| Inconel 600 | N06600 | 2.4816 | NC15FE11M | МНЖМц 28-2,5-1,5 | ЭИ868 | NA 13 | NCF 600 | NiCr15Fe |

| Inconel 601 | N06601 | 2.4851 | NC23FeA | XH60BT | ЭИ868 | NA 49 | NCF 601 | NiCr23Fe |

| Inconel 625 | N06625 | 2.4856 | NC22DNB4M | ХН75МБТЮ | ЭИ602 | NA 21 | NCF 625 | NiCr22Mo9Nb |

Chemical Composition of Inconel 600/ 601/ 625 Flanges

| Grade | Ni | Fe | C | Mn | Si | Cu | Cr | S | Mo | Co | Al | Ti | Nb |

| 600 | 72.0 min | 6.0 - 10.0 | 0.15 max | 1.0 max | 0.5 max | 0.5 max | 14.0 - 17.0 | 0.015 max | - | - | - | - | - |

| 601 | 58.0 – 63.0 | Balance | 0.10 max | 1.0 max | 0.50 max | 1.0 max | 21.0 – 25.0 | 0.015 max | 8.0-10.0 | - | 1.0 – 1.7 | - | - |

| 625 | 58.0 max | 5.0 max | 0.10 max | 0.50 max | 0.50 max | - | 20.0 - 23.0 | 0.015 max | 8.0 - 10.0 | 1.0 max | 0.40 max | 0.40 max | 3.15 - 4.15 |

Mechanical Properties of Inconel 600/ 601/ 625 Flanges

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

| 601 | 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

| 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

Other Types of Flanges of Inconel 600/ 601/ 625 Flanges

Dimensions Standard Of Inconel 600/ 601/ 625 Flanges

| Nominal Size | Outside Diameter (OD) | Min. Thickness (T) | RF Dia. (R) | No. of Bolt Holes | Diameter of Holes | Bolt Circle (BC) | SO Bore ID (SB) | WN Bore ID (WB) | Dia. Hub Base (HB) | Dia. of Hub Top (HT) | SO LTH (SL) | WN LTH (WL) |

| 1⁄2 | 3.50 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.50 | 1.05 | 0.56 | 2.00 |

| 1 | 4.25 | 0.50 | 2.00 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.50 | 4 | 0.62 | 3.50 | 1.70 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5.00 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.90 | 0.81 | 2.38 |

| 2 | 6.00 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7.00 | 0.81 | 4.12 | 4 | 0.75 | 5.50 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.50 | 0.88 | 5.00 | 4 | 0.75 | 6.00 | 3.57 | 3.07 | 4.25 | 3.50 | 1.12 | 2.69 |

| 31⁄2 | 8.50 | 0.88 | 5.50 | 8 | 0.75 | 7.00 | 4.07 | 3.55 | 4.81 | 4.00 | 1.19 | 2.75 |

| 4 | 9.00 | 0.88 | 6.19 | 8 | 0.75 | 7.50 | 4.57 | 4.03 | 5.31 | 4.50 | 1.25 | 2.94 |

| 5 | 10.00 | 0.88 | 7.31 | 8 | 0.88 | 8.50 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11.00 | 0.94 | 8.50 | 8 | 0.88 | 9.50 | 6.72 | 6.07 | 7.56 | 6.63 | 1.50 | 3.44 |

| 8 | 13.50 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16.00 | 1.12 | 12.75 | 12 | 1.00 | 14.25 | 10.88 | 10.02 | 12.00 | 10.75 | 1.88 | 3.94 |

| 12 | 19.00 | 1.19 | 15.00 | 12 | 1.00 | 17.00 | 12.88 | 12.00 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21.00 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14.00 | 2.19 | 4.94 |

| 16 | 23.50 | 1.38 | 18.50 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18.00 | 16.00 | 2.44 | 4.94 |

| 18 | 25.00 | 1.50 | 21.00 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18.00 | 2.62 | 5.44 |

| 20 | 27.50 | 1.62 | 23.00 | 20 | 1.25 | 25.00 | 20.20 | 19.25 | 22.00 | 20.00 | 2.81 | 5.62 |

| 22 | 29.50 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22.00 | 3.07 | 5.82 |

| 24 | 32.00 | 1.81 | 27.25 | 20 | 1.38 | 29.50 | 24.25 | 23.25 | 26.12 | 24.00 | 3.19 | 5.94 |

Size Of Inconel 600/ 601/ 625 Flanges

| Nom. Pipe Size | o | T1 | R | x | No.2/Dia. of Holes | Bolt Circle Dia. | L21 | H | B23 | L | B | r | L34 | B3 | D |

| 1/2 | 3.50 | 0.44 | 1.38 | 1.19 | 4-0.62 | 2.38 | 1.88 | 0.84 | 0.62 | 0.62 | 0.88 | 0.12 | 0.62 | 0.90 | 0.38 |

| 3/4 | 3.88 | 0.50 | 1.69 | 1.50 | 4-0.62 | 2.75 | 2.06 | 1.05 | 0.82 | 0.62 | 1.09 | 0.12 | 0.62 | 1.11 | 0.44 |

| 1 | 4.25 | 0.56 | 2.00 | 1.94 | 4-0.62 | 3.12 | 2.19 | 1.32 | 1.05 | 0.69 | 1.36 | 0.12 | 0.69 | 1.38 | 0.50 |

| 1-1/4 | 4.62 | 0.62 | 2.50 | 2.31 | 4-0.62 | 3.50 | 2.25 | 1.66 | 1.38 | 0.81 | 1.70 | 0.19 | 0.81 | 1.72 | 0.56 |

| 1-1/2 | 5.00 | 0.68 | 2.88 | 2.56 | 4-0.62 | 3.88 | 2.44 | 1.90 | 1.61 | 0.88 | 1.95 | 0.25 | 0.88 | 1.97 | 0.62 |

| 2 | 6.00 | 0.75 | 3.62 | 3.06 | 4-0.75 | 4.75 | 2.50 | 2.38 | 2.07 | 1.00 | 2.44 | 0.31 | 1.00 | 2.46 | 0.69 |

| 2-1/2 | 7.00 | 0.88 | 4.12 | 3.56 | 4-0.75 | 5.50 | 2.75 | 2.88 | 2.47 | 1.12 | 2.94 | 0.31 | 1.12 | 2.97 | 0.75 |

| 3 | 7.50 | 0.94 | 5.00 | 4.25 | 4-0.75 | 6.00 | 2.75 | 3.50 | 3.07 | 1.19 | 3.57 | 0.38 | 1.19 | 3.60 | 0.81 |

| 3-1/2 | 8.50 | 0.94 | 5.50 | 4.81 | 8-0.75 | 7.00 | 2.81 | 4.00 | 3.55 | 1.25 | 4.07 | 0.38 | 1.25 | 4.10 | 0.88 |

| 4 | 9.00 | 0.94 | 6.19 | 5.31 | 8-0.75 | 7.50 | 3.00 | 4.50 | 4.03 | 1.31 | 4.57 | 0.44 | 1.31 | 4.60 | 0.94 |

| 5 | 10.00 | 0.94 | 7.31 | 6.44 | 8-0.88 | 8.50 | 3.50 | 5.56 | 5.05 | 1.44 | 5.66 | 0.44 | 1.44 | 5.69 | 0.94 |

| 6 | 11.00 | 1.00 | 8.50 | 7.56 | 8-0.88 | 9.50 | 3.50 | 6.63 | 6.07 | 1.56 | 6.72 | 0.50 | 1.56 | 6.75 | 1.06 |

| 8 | 13.50 | 1.12 | 10.62 | 9.69 | 8-0.88 | 11.75 | 4.00 | 8.63 | 7.98 | 1.75 | 8.72 | 0.50 | 1.75 | 8.75 | 1.25 |

| 10 | 16.00 | 1.19 | 12.75 | 12.00 | 12-1.00 | 14.25 | 4.00 | 10.75 | 10.02 | 1.94 | 10.88 | 0.50 | 1.94 | 10.92 | 1.31 |

| 12 | 19.00 | 1.25 | 15.00 | 14.38 | 12-1.00 | 17.00 | 4.50 | 12.75 | 12.00 | 2.19 | 12.88 | 0.50 | 2.19 | 12.92 | 1.56 |

| 14 | 21.00 | 1.38 | 16.25 | 15.75 | 12-1.12 | 18.75 | 5.00 | 14.00 | 13.25 | 2.25 | 14.14 | 0.50 | 3.12 | 14.18 | 1.63 |

| 16 | 23.50 | 1.44 | 18.50 | 18.00 | 16-1.12 | 21.25 | 5.00 | 16.00 | 15.25 | 2.50 | 16.16 | 0.50 | 3.44 | 16.19 | 1.75 |

| 18 | 25.00 | 1.56 | 21.00 | 19.88 | 16-1.25 | 22.75 | 5.50 | 18.00 | 17.25 | 2.69 | 18.18 | 0.50 | 3.81 | 18.20 | 1.94 |

| 20 | 27.50 | 1.69 | 23.00 | 22.00 | 20-1.25 | 25.00 | 5.69 | 20.00 | 19.25 | 2.88 | 20.20 | 0.50 | 4.06 | 20.25 | 2.13 |

| 22 | 29.50 | 1.81 | 25.25 | 24.25 | 20-1.38 | 27.25 | 5.88 | 22.00 | 21.25 | 3.13 | 22.22 | 0.50 | 4.25 | 22.25 | 2.38 |

| 24 | 32.00 | 1.88 | 27.25 | 26.12 | 20-1.38 | 29.50 | 6.00 | 24.00 | 23.25 | 3.25 | 24.25 | 0.50 | 4.38 | 24.25 | 2.50 |

Weight Chart Of Inconel 600/ 601/ 625 Flanges

| Standard Of Flanges | Class Of Flanges | Diameter Of Flanges | Diameter Of Bolt Circle | Bolts Number | Size Of Bolt | Bolt Hole Diameter |

| AS4087 Flanges | PN14 Flanges | 95 | 67 | 4 | M12 | 14 |

| AS 2129 Flange | Table C Flanges | 95 | 67 | 4 | 13 | 14 |

| Table D Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table E Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table F Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table H Flanges | 114 | 83 | 4 | 16 | 17 | |

| Table J Flanges | 114 | 83 | 4 | 16 | 17 | |

| ANSI B16.5 Flanges | ANSI 150 Flanges | 89 | 60 | 4 | 13 | 16 |

| ANSI 300 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 600 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 900 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ANSI 1500 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ISO 7005 (DIN) Flange | PN6 Flanges | 80 | 55 | 4 | M10 | 11 |

| PN10 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN16 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN20 Flanges | 90 | 60.5 | 4 | M14 | 16 | |

| PN25 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN40 Flanges | 95 | 65 | 4 | M12 | 14 |

Pressure Rating Of Inconel 600/ 601/ 625 Flanges

| Temp. ℃ | Pressure-ASME temperature rating for B16.47 by class, bar | |||||

| 75 | 150 | 300 | 400 | 600 | 900 | |

| -29 to 38 | 10.0 | 20.0 | 51.7 | 68.9 | 103.4 | 155.1 |

| 50 | 9.8 | 19.5 | 51.7 | 68.9 | 103.4 | 155.1 |

| 100 | 8.8 | 17.7 | 50.7 | 67.5 | 101.3 | 152.0 |

| 150 | 7.9 | 15.8 | 45.9 | 61.2 | 91.9 | 137.8 |

| 200 | 6.9 | 13.8 | 42.7 | 56.9 | 85.3 | 128.0 |

| 250 | 6.0 | 12.1 | 40.5 | 53.9 | 80.9 | 121.4 |

| 300 | 5.1 | 10.2 | 38.9 | 51.8 | 77.7 | 116.6 |

industrial use flanges for Inconel 600/ 601/ 625 Flanges

Price Of Inconel 600/ 601/ 625 Flanges

| High Nickel Alloys Forged Flanges | USD $8.10 - $20.20 / Piece (FOB Price) on request |

| High Nickel Alloys Blind Flanges | USD $8.10 - $20.20 / Piece (FOB Price) on request |

| High Nickel Alloys Slip On Flange | USD $8.10 - $20.20 / Piece (FOB Price) on request |

| High Nickel Alloys Socketweld Flanges | USD $8.10 - $20.20 / Piece (FOB Price) on request |

| High Nickel Alloys Long Weld Neck Flanges | USD $8.10 - $20.20 / Piece (FOB Price) on request |

Application Of Inconel 600/ 601/ 625 Flanges

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Inconel 600/ 601/ 625 Flanges

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

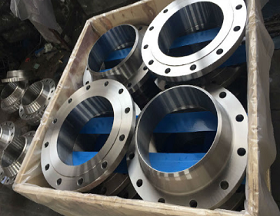

Packing Of Inconel 600/ 601/ 625 Flanges

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

Inconel 625 SWRF Flanges Price Per Kg, Inconel Alloy 601 Groove & Tongue Flanges Price Per Kg, ASTM B564 Inconel 600 SORF Flanges Weight Chart, DIN 2.4851 Reducing Flanges Price List, UNS N06600 WNRF Flanges Price List In India, DIN 2.4856 RTJ Flanges Catalogue, Inconel Alloy 601 Blind Flange Price List, ASTM B564 Inconel 600 Forged Flanges Weight Chart, DIN 2.4851 Forging Facing Flanges Price List In India.

Inconel Alloy 601 Flanges Bolts Exporter in Patna, UNS N06600 WNRF Flanges Stockist in Karnataka, Inconel Alloy 601 Blind Flange Stockist in Pimpri-Chinchwad, Inconel 625 SWRF Flanges Manufacturer in Lucknow, ASTM B564 Inconel 600 Forged Flanges Manufacturer in Bengaluru, UNS N06601 Orifice Flanges Stockist in Bangalore, Inconel Alloy 601 Longweld Neck Flange Supplier in Pune, Inconel 625 Slip On Flange Supplier in Coimbatore, DIN 2.4856 RTJ Flanges Stockist in Gujarat.

Inconel Alloy 601 Flanges Bolts Exporter in Syria, 625 Inconel Weldo / Nipo Flanges Exporter in Indonesia, DIN 2.4816 Threaded Flanges Stockist in Malaysia, UNS N06600 WNRF Flanges Stockist in Saudi Arabia, DIN 2.4851 Reducing Flanges Manufacturer in Vietnam, Inconel Alloy 601 Blind Flange Stockist in UK, Inconel 625 Slip On Flange Supplier in Saudi Arabia, 625 Inconel Spades Ring Spacers Flanges Manufacturer in Tunisia.