Inconel 600/ 601/ 625 Forged fitting

UNS N06600 Cross, 625 Inconel Adaptor, ASTM A182 Inconel 600 Threaded Hex Nipple, DIN 2.4851 Round Plug, DIN 2.4816 Threaded Street Elbow, ASME SA182 Inconel 625 Full Coupling.

About Inconel 600/ 601/ 625 Forged fitting

Nissan Steel is a distributor and supplier of Inconel 625 Forged Fittings, named after the percentages of chromium (22%) and nickel (5%) in the alloy. These fittings are available in various grades, including Inconel 600 Socketweld Fittings and Inconel 601 Forged Fittings. The mixed austenitic-ferritic structure is a primary benefit of Inconel 625 Socketwel Fittings, as is their low cost. These fittings are used to construct paper mills, liquor storage tanks, and pulp and paper digesters.

Although Inconel Forged Threaded Tee Fittings resist stress corrosion cracking, they are not as resistant to this attack as ferritic stainless steel. Compared to austenitic stainless steels, Inconel 625 Socket Weld Tee Fittings have lower thermal expansion and greater thermal conductivity. Inconel 600 Threaded Elbow Fittings are often used in the Nuclear Sector and the Oil and Gas industry, among other applications. Inconel 625 Forged Elbow Fittings can be effectively used as a substitute for 300 series austenitic stainless steels in almost all equipment where superior mechanical power and lighter weight are required, thanks to their socket-welding forging technique.

The Inconel Forged Threaded Cross Fittings come in various shapes and tempers that can impact the mechanical qualities of the fittings. Additionally, the alloying elements in Inconel Forged Socket Weld Cross Fittings can affect the temperature at which steel reaches its eutectoid state.

ASTM A182 Inconel 600 45 Degree Elbow Manufacturer, DIN 2.4851 Threaded Lateral Outlet Supplier, UNS N06625 Threaded Plug Manufacturer, Inconel 601 90 Degree Elbow Stockist.

Specification of Inconel 600/ 601/ 625 Forged fitting

| Specification | ASTM B564 / ASME SB564 |

| Dimension Standard | ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799 |

| Size | 1/8" NB to 4" NB |

| Type | Socketweld Fittings, Screwed-Threaded Fittings |

| Pressure-Temperature Class | Threaded End - 2000 /3000/ 6000 LBS. Socket-weld End - 3000 / 6000/ 9000 LBS. |

Ready stock of available for Inconel 600/ 601/ 625 Forged fitting

Equivalent Grades of Inconel 600/ 601/ 625 Forged fitting

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | GOST | OR | BS | JIS | EN |

| Inconel 600 | N06600 | 2.4816 | NC15FE11M | МНЖМц 28-2,5-1,5 | ЭИ868 | NA 13 | NCF 600 | NiCr15Fe |

| Inconel 601 | N06601 | 2.4851 | NC23FeA | XH60BT | ЭИ868 | NA 49 | NCF 601 | NiCr23Fe |

| Inconel 625 | N06625 | 2.4856 | NC22DNB4M | ХН75МБТЮ | ЭИ602 | NA 21 | NCF 625 | NiCr22Mo9Nb |

Chemical Composition of Inconel 600/ 601/ 625 Forged fitting

| Grade | Ni | Fe | C | Mn | Si | Cu | Cr | S | Mo | Co | Al | Ti | Nb |

| 600 | 72.0 min | 6.0 - 10.0 | 0.15 max | 1.0 max | 0.5 max | 0.5 max | 14.0 - 17.0 | 0.015 max | - | - | - | - | - |

| 601 | 58.0 – 63.0 | Balance | 0.10 max | 1.0 max | 0.50 max | 1.0 max | 21.0 – 25.0 | 0.015 max | 8.0-10.0 | - | 1.0 – 1.7 | - | - |

| 625 | 58.0 max | 5.0 max | 0.10 max | 0.50 max | 0.50 max | - | 20.0 - 23.0 | 0.015 max | 8.0 - 10.0 | 1.0 max | 0.40 max | 0.40 max | 3.15 - 4.15 |

Mechanical Properties of Inconel 600/ 601/ 625 Forged fitting

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

| 601 | 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

| 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

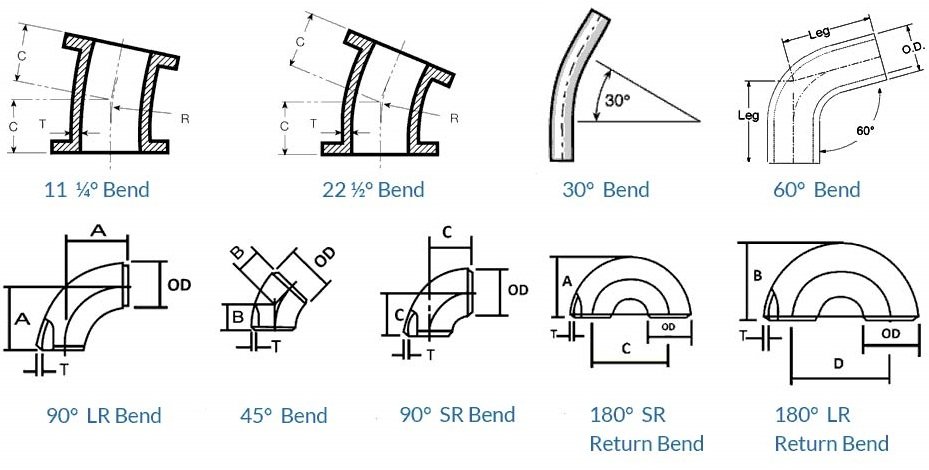

Other Types of Inconel 600/ 601/ 625 Forged fitting

Dimensions Standard Of Inconel 600/ 601/ 625 Forged fitting

| ASME b16.9 Fittings Normal Pipe Size | ANSI b16 9 Pipe Fitting O D Y | Wall Thickness T (Pipe Elbow Sch.) | LR 45 Deg Elbows Centre to Face B | SR 45 Deg Elbows Weight | LR 90 Deg Elbows Centre to Face A | LR 90 Deg Elbows Weight In Below | SR 90 Deg Elbows Centre to Face A | SR 90 Deg Elbows Weight In Below | ||

| mm | inch | mm | mm | Schedule | mm | kg | mm | kg | mm | kg |

| 15 | 1/2” | 21.3 | 2.78 | STD | 15.9 | 0.04 | 38.1 | 0.08 | – | – |

| 3.73 | X.S | 15.9 | 0.05 | 38.1 | 0.10 | – | – | |||

| 20 | 3/4” | 26.7 | 2.87 | STD | 11.1 | 0.04 | 28.6 | 0.08 | – | – |

| 3.91 | X.S | 11.1 | 0.05 | 28.6 | 0.11 | – | – | |||

| 25 | 1” | 33.4 | 3.38 | STD | 22.2 | 0.09 | 38.1 | 0.15 | 25.4 | 0.11 |

| 4.55 | X.S | 22.2 | 0.11 | 38.1 | 0.19 | 25.4 | 0.14 | |||

| 32 | 11/4” | 42.2 | 3.56 | STD | 25.4 | 0.14 | 47.6 | 0.28 | 31.75 | 0.18 |

| 4.85 | X.S | 25.4 | 0.2 | 47.6 | 0.39 | 31.75 | 0.24 | |||

| 40 | 11/2” | 48.3 | 3.68 | STD | 28.6 | 0.2 | 57.1 | 0.4 | 38.1 | 0.26 |

| 5.08 | X.S | 28.6 | 0.25 | 57.1 | 0.5 | 38.1 | 0.35 | |||

| 50 | 2” | 60.3 | 3.91 | STD | 34.9 | 0.36 | 76.2 | 0.72 | 50.8 | 0.5 |

| 5.54 | X.S | 34.9 | 0.5 | 76.2 | 1.0 | 50.8 | 0.68 | |||

| 65 | 21/2” | 73.0 | 5.16 | STD | 44.4 | 0.73 | 95.2 | 1.46 | 63.5 | 0.95 |

| 7.01 | X.S | 44.4 | 0.91 | 95.2 | 1.82 | 63.5 | 1.27 | |||

| 80 | 3” | 88.9 | 5.49 | STD | 50.8 | 1.1 | 114.3 | 2.18 | 76.2 | 1.45 |

| 7.62 | X.S | 50.8 | 1.45 | 114.3 | 2.86 | 76.2 | 1.95 | |||

| 100 | 4” | 114.3 | 6.02 | STD | 63.5 | 2.1 | 152.4 | 4.2 | 101.6 | 2.8 |

| 8.56 | X.S | 63.5 | 2.9 | 152.4 | 5.7 | 101.6 | 3.9 | |||

| 125 | 5” | 141.3 | 6.65 | STD | 79.4 | 3.4 | 190.0 | 6.8 | 127.0 | 4.8 |

| 9.5 | X.S | 79.4 | 5.0 | 190.0 | 10.0 | 127.0 | 6.5 | |||

| 150 | 6” | 168.3 | 7.11 | STD | 95.2 | 5.1 | 229.0 | 10.1 | 152.4 | 6.8 |

| 10.97 | X.S | 95.2 | 7.7 | 229.0 | 15.3 | 152.4 | 10.2 | |||

| 200 | 8” | 219.1 | 8.18 | STD | 127.0 | 10.2 | 305.0 | 20.4 | 203.0 | 13.6 |

| 12.7 | X.S | 127.0 | 15.5 | 305.0 | 30.9 | 203.0 | 20.9 | |||

| 250 | 10” | 273.9 | 9.27 | STD | 159.0 | 18.1 | 381.0 | 36.1 | 254.0 | 24.1 |

| 12.7 | X.S | 159.0 | 24.4 | 381.0 | 48.8 | 254.0 | 32.5 | |||

| 300 | 12” | 323.9 | 9.52 | STD | 190.0 | 26.6 | 457.0 | 53.1 | 305.0 | 35.4 |

| 12.7 | X.S | 190.0 | 35.0 | 457.0 | 70.0 | 305.0 | 46.7 | |||

| 350 | 14” | 355.6 | 9.52 | STD | 222.0 | 34.1 | 533.0 | 68.1 | 356.0 | 45.4 |

| 12.7 | X.S | 222.0 | 45.0 | 533.0 | 90.0 | 356.0 | 60.0 | |||

| 400 | 16” | 406.4 | 9.52 | STD | 254.0 | 45.0 | 610.0 | 89.3 | 406.0 | 59.5 |

| 12.7 | X.S | 254.0 | 59.0 | 610.0 | 118.0 | 406.0 | 78.7 | |||

| 450 | 18” | 457.0 | 9.52 | STD | 286.0 | 56.5 | 686.0 | 113.0 | 457.0 | 75.6 |

| 12.7 | X.S | 286.0 | 75.0 | 686.0 | 150.0 | 457.0 | 100.0 | |||

| 500 | 20” | 508.0 | 9.52 | STD | 318.0 | 85.0 | 762.0 | 140.0 | 508.0 | 93.5 |

| 12.7 | X.S | 318.0 | 112.5 | 762.0 | 186.0 | 508.0 | 124.0 | |||

| 600 | 24” | 610.00 | 9.52 | STD | 381.0 | 101.5 | 914.0 | 203.0 | 610.0 | 135.0 |

| 12.7 | X.S | 381.0 | 134.5 | 914.0 | 269.0 | 610.0 | 179.0 | |||

Size Of Inconel 600/ 601/ 625 Forged fitting

| NPS (inch) | Pipe Schedule. | OD (inch) | Wall Thick. (in) | Temperature | ||||

| 100 Fitting | 200 Fitting | 300 Fitting | 400 Fitting | 500 Fitting | ||||

| Allowable Stress | ||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | ||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 |

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | |

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | |

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 |

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | |

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | |

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 |

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | |

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | |

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 |

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | |

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | |

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 |

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | |

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | |

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 |

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | |

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | |

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 |

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | |

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | |

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 |

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | |

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | |

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 |

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | |

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | |

Weight Chart Of Inconel 600/ 601/ 625 Forged fitting

| Normal Pipe Sizes | A | B | QTY | Weight In KG |

| ¼ | 0.81 | 0.88 | 160 | 0.20 |

| ⁄ | 0.97 | 1.00 | 130 | 0.26 |

| ½ | 1.12 | 1.31 | 100 | 0.57 |

| ¾ | 1.31 | 1.5 | 75 | 0.71 |

| 1 | 1.5 | 1.81 | 40 | 1.08 |

| 1 ¼ | 1.75 | 2.19 | 25 | 1.68 |

| 1 ½ | 2.00 | 2.44 | 18 | 2.38 |

| 2 | 2.38 | 2.97 | 10 | 3.55 |

| 2 ½ | 3.00 | 3.62 | 4 | 6.22 |

| 3 | 3.38 | 4.31 | 2 | 10.36 |

| 4 | 4.19 | 5.75 | 1 | 23.91 |

Pressure Rating Of Inconel 600/ 601/ 625 Forged fitting

| Pressure-Temperature | |||||

| Temperature | Class | ||||

| 150 | 300 | ||||

| 1/4 - 1 inch. | 1 1/4 - 2 inch. | 2 1/2 - 3 inch. | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | - | 935 | 750 | 560 |

| 450 | 232 | - | 725 | 600 | 475 |

| 500 | 260 | - | 510 | 450 | 385 |

| 550 | 288 | - | 300 | 300 | 300 |

industrial use fitting for Inconel 600/ 601/ 625 Forged fitting

Price Of Inconel 600/ 601/ 625 Forged fitting

| High Nickel Alloys Elbow | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Equal Tee | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Reducing Tee | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Cross | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Cap | USD $8.11 - $20.21 / Piece (FOB Price) on request |

Application Of Inconel 600/ 601/ 625 Forged fitting

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Inconel 600/ 601/ 625 Forged fitting

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

Packing Of Inconel 600/ 601/ 625 Forged fitting

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates