Inconel 718/ 825 Forged fitting

UNS N07718 Lateral Tee, DIN 2.4668 Exhaust Pipe Reducer, ASTM B564 Inconel 718 1D Elbow, Inconel 718 Buttweld Welded Cap, Inconel 718 Contcentric Reducer.

About Inconel 718/ 825 Forged fitting

Nissan Steel is a well-known company in the industry that produces reinforced and hardened Inconel 718 Forged Fittings using a technique called cold work. Our company manufactures these fittings for various industrial applications, including steam super-heater tube supports and catalyst support grids used to produce nitric acid. In the forging process of these Inconel 825 Fittings, we use a combination of chromium, nickel, and molybdenum, which provide excellent resistance to heat corrosion in various settings. Our custom-made Inconel 718 Socketweld Fittings are designed to provide outstanding resistance to high-temperature environments with modest amounts of sulphur, making them ideal for various applications.

At Nissan Steel, we forge these fittings in sizes and forms per our customers’ requirements to fulfil their needs. We are globally recognized as the most reliable and respected distributor of Inconel Forged Fittings. Our fittings are priced competitively and never increase from the low starting point we consistently maintain. We maintain the highest level of quality for our Inconel 825 Fittings, using only the finest raw materials and an expert team with extensive knowledge and experience. We prioritize national and international standards to ensure the quality of our products. To ensure the highest quality, we put our Inconel 718 Forged Fittings through various types of destructive and non-destructive testing at different production stages. After verifying their quality and characteristics, we package them appropriately for shipment. Our production facility is equipped with state-of-the-art technology and the latest equipment and techniques, enabling us to create large quantities of ready stock and fulfil urgent customer orders.

At Nissan Steel, we also have warehouses where we keep our products in great condition, ensuring they are not damaged in any way. We pride ourselves on providing prompt and damage-free service to our customers and a variety of after-sale services for their convenience.

Inconel 718 Long Stud End Exporter, Inconel 718 Buttweld Welded Cap Exporter, ASME SB564 Inconel 718 Buttweld Reducer Exporter, ASME SB564 Inconel 718 Equal Cross Stockist.

Specification of Inconel 718/ 825 Forged fitting

| Specification | ASTM B564 / ASME SB564 |

| Dimension Standard | ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799 |

| Size | 1/8" NB to 4" NB |

| Type | Socketweld Fittings, Screwed-Threaded Fittings |

| Pressure-Temperature Class | Threaded End - 2000 /3000/ 6000 LBS. Socket-weld End - 3000 / 6000/ 9000 LBS. |

Ready stock of available for Inconel 718/ 825 Forged fitting

Equivalent Grades of Inconel 718/ 825 Forged fitting

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 718 | 2.4668 | N07718 | - | - | - | - | - |

| Incoloy 825 | 2.4858 | N08825 | NCF 825 | NA 16 | ЭП703 | NFE30C20DUM | NiCr21Mo |

Chemical Composition of Inconel 718/ 825 Forged fitting

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015 max | 0.30 max | - | 50.00 - 55.00 | 17.00 - 21.00 |

| 825 | 0.05 max | 1.00 max | 0.5 max | 0.03 max | 1.50 – 3.00 | 22.00 min | 38.00 – 46.00 | 19.50 – 23.50 |

Mechanical Properties of Inconel 718/ 825 Forged fitting

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 718 | 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 482 | 45 % |

| 825 | 8.14 g/cm3 | 1400 °C (2550 °F) | Psi – 80,000 , MPa – 550 | Psi – 32,000 , MPa – 220 | 30 % |

Other Types of Inconel 718/ 825 Forged fitting

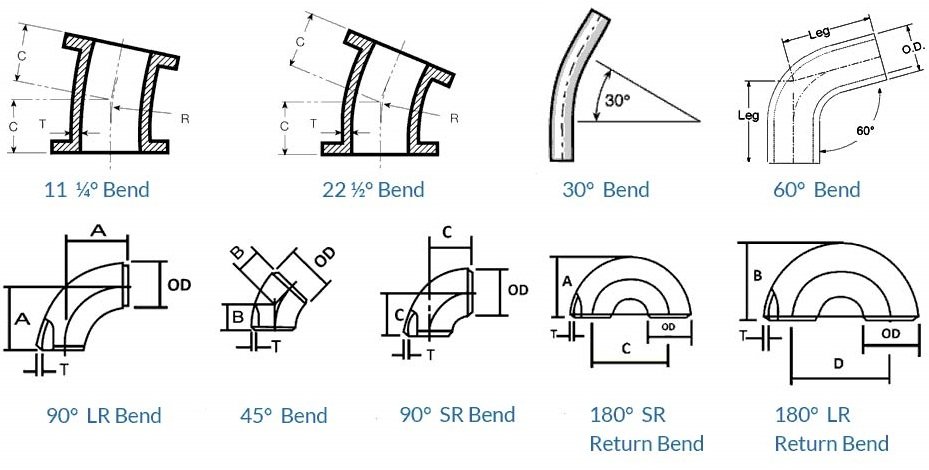

Dimensions Standard Of Inconel 718/ 825 Forged fitting

| ASME b16.9 Fittings Normal Pipe Size | ANSI b16 9 Pipe Fitting O D Y | Wall Thickness T (Pipe Elbow Sch.) | LR 45 Deg Elbows Centre to Face B | SR 45 Deg Elbows Weight | LR 90 Deg Elbows Centre to Face A | LR 90 Deg Elbows Weight In Below | SR 90 Deg Elbows Centre to Face A | SR 90 Deg Elbows Weight In Below | ||

| mm | inch | mm | mm | Schedule | mm | kg | mm | kg | mm | kg |

| 15 | 1/2” | 21.3 | 2.78 | STD | 15.9 | 0.04 | 38.1 | 0.08 | – | – |

| 3.73 | X.S | 15.9 | 0.05 | 38.1 | 0.10 | – | – | |||

| 20 | 3/4” | 26.7 | 2.87 | STD | 11.1 | 0.04 | 28.6 | 0.08 | – | – |

| 3.91 | X.S | 11.1 | 0.05 | 28.6 | 0.11 | – | – | |||

| 25 | 1” | 33.4 | 3.38 | STD | 22.2 | 0.09 | 38.1 | 0.15 | 25.4 | 0.11 |

| 4.55 | X.S | 22.2 | 0.11 | 38.1 | 0.19 | 25.4 | 0.14 | |||

| 32 | 11/4” | 42.2 | 3.56 | STD | 25.4 | 0.14 | 47.6 | 0.28 | 31.75 | 0.18 |

| 4.85 | X.S | 25.4 | 0.2 | 47.6 | 0.39 | 31.75 | 0.24 | |||

| 40 | 11/2” | 48.3 | 3.68 | STD | 28.6 | 0.2 | 57.1 | 0.4 | 38.1 | 0.26 |

| 5.08 | X.S | 28.6 | 0.25 | 57.1 | 0.5 | 38.1 | 0.35 | |||

| 50 | 2” | 60.3 | 3.91 | STD | 34.9 | 0.36 | 76.2 | 0.72 | 50.8 | 0.5 |

| 5.54 | X.S | 34.9 | 0.5 | 76.2 | 1.0 | 50.8 | 0.68 | |||

| 65 | 21/2” | 73.0 | 5.16 | STD | 44.4 | 0.73 | 95.2 | 1.46 | 63.5 | 0.95 |

| 7.01 | X.S | 44.4 | 0.91 | 95.2 | 1.82 | 63.5 | 1.27 | |||

| 80 | 3” | 88.9 | 5.49 | STD | 50.8 | 1.1 | 114.3 | 2.18 | 76.2 | 1.45 |

| 7.62 | X.S | 50.8 | 1.45 | 114.3 | 2.86 | 76.2 | 1.95 | |||

| 100 | 4” | 114.3 | 6.02 | STD | 63.5 | 2.1 | 152.4 | 4.2 | 101.6 | 2.8 |

| 8.56 | X.S | 63.5 | 2.9 | 152.4 | 5.7 | 101.6 | 3.9 | |||

| 125 | 5” | 141.3 | 6.65 | STD | 79.4 | 3.4 | 190.0 | 6.8 | 127.0 | 4.8 |

| 9.5 | X.S | 79.4 | 5.0 | 190.0 | 10.0 | 127.0 | 6.5 | |||

| 150 | 6” | 168.3 | 7.11 | STD | 95.2 | 5.1 | 229.0 | 10.1 | 152.4 | 6.8 |

| 10.97 | X.S | 95.2 | 7.7 | 229.0 | 15.3 | 152.4 | 10.2 | |||

| 200 | 8” | 219.1 | 8.18 | STD | 127.0 | 10.2 | 305.0 | 20.4 | 203.0 | 13.6 |

| 12.7 | X.S | 127.0 | 15.5 | 305.0 | 30.9 | 203.0 | 20.9 | |||

| 250 | 10” | 273.9 | 9.27 | STD | 159.0 | 18.1 | 381.0 | 36.1 | 254.0 | 24.1 |

| 12.7 | X.S | 159.0 | 24.4 | 381.0 | 48.8 | 254.0 | 32.5 | |||

| 300 | 12” | 323.9 | 9.52 | STD | 190.0 | 26.6 | 457.0 | 53.1 | 305.0 | 35.4 |

| 12.7 | X.S | 190.0 | 35.0 | 457.0 | 70.0 | 305.0 | 46.7 | |||

| 350 | 14” | 355.6 | 9.52 | STD | 222.0 | 34.1 | 533.0 | 68.1 | 356.0 | 45.4 |

| 12.7 | X.S | 222.0 | 45.0 | 533.0 | 90.0 | 356.0 | 60.0 | |||

| 400 | 16” | 406.4 | 9.52 | STD | 254.0 | 45.0 | 610.0 | 89.3 | 406.0 | 59.5 |

| 12.7 | X.S | 254.0 | 59.0 | 610.0 | 118.0 | 406.0 | 78.7 | |||

| 450 | 18” | 457.0 | 9.52 | STD | 286.0 | 56.5 | 686.0 | 113.0 | 457.0 | 75.6 |

| 12.7 | X.S | 286.0 | 75.0 | 686.0 | 150.0 | 457.0 | 100.0 | |||

| 500 | 20” | 508.0 | 9.52 | STD | 318.0 | 85.0 | 762.0 | 140.0 | 508.0 | 93.5 |

| 12.7 | X.S | 318.0 | 112.5 | 762.0 | 186.0 | 508.0 | 124.0 | |||

| 600 | 24” | 610.00 | 9.52 | STD | 381.0 | 101.5 | 914.0 | 203.0 | 610.0 | 135.0 |

| 12.7 | X.S | 381.0 | 134.5 | 914.0 | 269.0 | 610.0 | 179.0 | |||

Size Of Inconel 718/ 825 Forged fitting

| NPS (inch) | Pipe Schedule. | OD (inch) | Wall Thick. (in) | Temperature | ||||

| 100 Fitting | 200 Fitting | 300 Fitting | 400 Fitting | 500 Fitting | ||||

| Allowable Stress | ||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | ||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 |

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | |

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | |

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 |

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | |

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | |

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 |

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | |

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | |

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 |

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | |

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | |

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 |

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | |

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | |

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 |

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | |

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | |

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 |

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | |

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | |

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 |

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | |

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | |

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 |

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | |

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | |

Weight Chart Of Inconel 718/ 825 Forged fitting

| Normal Pipe Sizes | A | B | QTY | Weight In KG |

| ¼ | 0.81 | 0.88 | 160 | 0.20 |

| ⁄ | 0.97 | 1.00 | 130 | 0.26 |

| ½ | 1.12 | 1.31 | 100 | 0.57 |

| ¾ | 1.31 | 1.5 | 75 | 0.71 |

| 1 | 1.5 | 1.81 | 40 | 1.08 |

| 1 ¼ | 1.75 | 2.19 | 25 | 1.68 |

| 1 ½ | 2.00 | 2.44 | 18 | 2.38 |

| 2 | 2.38 | 2.97 | 10 | 3.55 |

| 2 ½ | 3.00 | 3.62 | 4 | 6.22 |

| 3 | 3.38 | 4.31 | 2 | 10.36 |

| 4 | 4.19 | 5.75 | 1 | 23.91 |

Pressure Rating Of Inconel 718/ 825 Forged fitting

| Pressure-Temperature | |||||

| Temperature | Class | ||||

| 150 | 300 | ||||

| 1/4 - 1 inch. | 1 1/4 - 2 inch. | 2 1/2 - 3 inch. | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | - | 935 | 750 | 560 |

| 450 | 232 | - | 725 | 600 | 475 |

| 500 | 260 | - | 510 | 450 | 385 |

| 550 | 288 | - | 300 | 300 | 300 |

industrial use fitting for Inconel 718/ 825 Forged fitting

Price Of Inconel 718/ 825 Forged fitting

| High Nickel Alloys Elbow | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Equal Tee | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Reducing Tee | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Cross | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Cap | USD $8.11 - $20.21 / Piece (FOB Price) on request |

Application Of Inconel 718/ 825 Forged fitting

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Inconel 718/ 825 Forged fitting

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

Packing Of Inconel 718/ 825 Forged fitting

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates