Monel 400/ K500 Forged fitting

DIN 2.4375 Round Plug, DIN 2.4375 Threaded Lateral Outlet, 400 Monel Adaptor, K500 Monel Union, Monel 400 Threaded 45 Lateral Tee, Monel Alloys K500 Threaded Swage Nipple, K500 Monel Threaded Equal.

About Monel 400/ K500 Forged fitting

Nissan Steel is a corporation that produces a wide range of products using carefully selected machinery that supports and facilitates manufacturing processes. One of the products they manufacture in significant quantities is Monel K500 Forged Fittings. Monel 400 Forged Fittings are one example of the products that can be manufactured using Monel composite. These fittings are widely used in various industrial and commercial applications due to their durability and stunning appearance. The nickel alloys used in these fittings primarily consist of nickel and copper, with smaller amounts of manganese, iron, silicon, and carbon. The composite is highly resistant to corrosion caused by various agents, such as salt water. Rapid production of monel fittings is possible through cold and hot working, welding, and machining. These fittings are ideal for high weight, vibration, and adverse conditions.

Monel 400 Forged Fittings are employed in various sectors, including water supply systems and oil and gas pipelines. These industries extensively use items from this category. Without these fittings, plumbing jobs would be considered incomplete. Manufacturers subject the fabricated fittings to a series of tests and inquiries to determine their quality. The tests include pitting obstruction, outsider assessment, visual review, and PMI tests. After the testing, the fittings are packed to prevent corrosion and damage. Production involves using premium-grade products and paying close attention to quality criteria following global rules. These products are widely used in etrochemicals, natural gas, and petroleum refineries. They are available in various sizes and can be modified to meet individual consumer needs.

DIN 2.4360 Half Coupling Stockist, DIN 2.4375 Threaded Lateral Outlet Supplier, ASME SB564 Monel 400 Reducer Insert Exporter, Monel 400 Tee Supplier.

Specification of Monel 400/ K500 Forged fitting

| Specification | ASTM B564 / ASME SB564 |

| Dimension Standard | ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799 |

| Size | 1/8" NB to 4" NB |

| Type | Socketweld Fittings, Screwed-Threaded Fittings |

| Pressure-Temperature Class | Threaded End - 2000 /3000/ 6000 LBS. Socket-weld End - 3000 / 6000/ 9000 LBS. |

Ready stock of available for Monel 400/ K500 Forged fitting

Equivalent Grades of Monel 400/ K500 Forged fitting

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Monel 400 | 2.4360 | N04400 | NW 4400 | NA 13 | МНЖМц 28-2,5-1,5 | NU-30M | NiCu30Fe |

| Monel K500 | 2.4375 | N05500 | - | - | - | - | - |

Chemical Composition of Monel 400/ K500 Forged fitting

| Grade | Ni | Fe | C | Mn | Si | Cu | Al | Ti | S |

| 400 | 63.0- 70.00 max | 2.50 max | 0.3 max | 2.00 max | 0.50 max | Remainder | - | - | 0.024 max |

| K500 | 63.0 min | 05 - 2 | 0.25 max | 1.5 max | 0.5 max | 27.0 - 33.0 | 2.3 - 3.15 | 0.35 - 0.85 | 0.010 max |

Mechanical Properties of Monel 400/ K500 Forged fitting

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Monel 400 | 8.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80,000 , MPa – 550 | Psi – 35,000 , MPa – 240 | 40 % |

| Monel K500 | 8.44 g/cm3 | 1350 °C (2460 °F) | Psi – 160000 , MPa – 1100 | Psi – 115000 , MPa – 790 | 20 % |

Other Types of Monel 400/ K500 Forged fitting

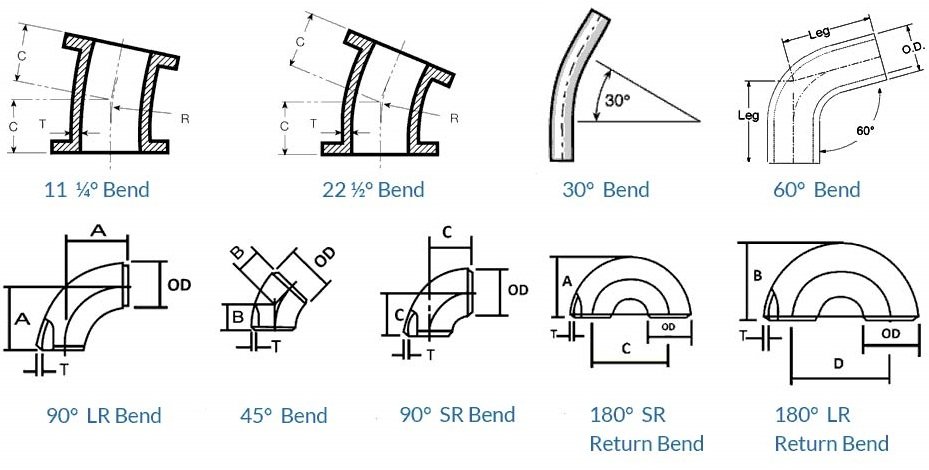

Dimensions Standard Of Monel 400/ K500 Forged fitting

| ASME b16.9 Fittings Normal Pipe Size | ANSI b16 9 Pipe Fitting O D Y | Wall Thickness T (Pipe Elbow Sch.) | LR 45 Deg Elbows Centre to Face B | SR 45 Deg Elbows Weight | LR 90 Deg Elbows Centre to Face A | LR 90 Deg Elbows Weight In Below | SR 90 Deg Elbows Centre to Face A | SR 90 Deg Elbows Weight In Below | ||

| mm | inch | mm | mm | Schedule | mm | kg | mm | kg | mm | kg |

| 15 | 1/2” | 21.3 | 2.78 | STD | 15.9 | 0.04 | 38.1 | 0.08 | – | – |

| 3.73 | X.S | 15.9 | 0.05 | 38.1 | 0.10 | – | – | |||

| 20 | 3/4” | 26.7 | 2.87 | STD | 11.1 | 0.04 | 28.6 | 0.08 | – | – |

| 3.91 | X.S | 11.1 | 0.05 | 28.6 | 0.11 | – | – | |||

| 25 | 1” | 33.4 | 3.38 | STD | 22.2 | 0.09 | 38.1 | 0.15 | 25.4 | 0.11 |

| 4.55 | X.S | 22.2 | 0.11 | 38.1 | 0.19 | 25.4 | 0.14 | |||

| 32 | 11/4” | 42.2 | 3.56 | STD | 25.4 | 0.14 | 47.6 | 0.28 | 31.75 | 0.18 |

| 4.85 | X.S | 25.4 | 0.2 | 47.6 | 0.39 | 31.75 | 0.24 | |||

| 40 | 11/2” | 48.3 | 3.68 | STD | 28.6 | 0.2 | 57.1 | 0.4 | 38.1 | 0.26 |

| 5.08 | X.S | 28.6 | 0.25 | 57.1 | 0.5 | 38.1 | 0.35 | |||

| 50 | 2” | 60.3 | 3.91 | STD | 34.9 | 0.36 | 76.2 | 0.72 | 50.8 | 0.5 |

| 5.54 | X.S | 34.9 | 0.5 | 76.2 | 1.0 | 50.8 | 0.68 | |||

| 65 | 21/2” | 73.0 | 5.16 | STD | 44.4 | 0.73 | 95.2 | 1.46 | 63.5 | 0.95 |

| 7.01 | X.S | 44.4 | 0.91 | 95.2 | 1.82 | 63.5 | 1.27 | |||

| 80 | 3” | 88.9 | 5.49 | STD | 50.8 | 1.1 | 114.3 | 2.18 | 76.2 | 1.45 |

| 7.62 | X.S | 50.8 | 1.45 | 114.3 | 2.86 | 76.2 | 1.95 | |||

| 100 | 4” | 114.3 | 6.02 | STD | 63.5 | 2.1 | 152.4 | 4.2 | 101.6 | 2.8 |

| 8.56 | X.S | 63.5 | 2.9 | 152.4 | 5.7 | 101.6 | 3.9 | |||

| 125 | 5” | 141.3 | 6.65 | STD | 79.4 | 3.4 | 190.0 | 6.8 | 127.0 | 4.8 |

| 9.5 | X.S | 79.4 | 5.0 | 190.0 | 10.0 | 127.0 | 6.5 | |||

| 150 | 6” | 168.3 | 7.11 | STD | 95.2 | 5.1 | 229.0 | 10.1 | 152.4 | 6.8 |

| 10.97 | X.S | 95.2 | 7.7 | 229.0 | 15.3 | 152.4 | 10.2 | |||

| 200 | 8” | 219.1 | 8.18 | STD | 127.0 | 10.2 | 305.0 | 20.4 | 203.0 | 13.6 |

| 12.7 | X.S | 127.0 | 15.5 | 305.0 | 30.9 | 203.0 | 20.9 | |||

| 250 | 10” | 273.9 | 9.27 | STD | 159.0 | 18.1 | 381.0 | 36.1 | 254.0 | 24.1 |

| 12.7 | X.S | 159.0 | 24.4 | 381.0 | 48.8 | 254.0 | 32.5 | |||

| 300 | 12” | 323.9 | 9.52 | STD | 190.0 | 26.6 | 457.0 | 53.1 | 305.0 | 35.4 |

| 12.7 | X.S | 190.0 | 35.0 | 457.0 | 70.0 | 305.0 | 46.7 | |||

| 350 | 14” | 355.6 | 9.52 | STD | 222.0 | 34.1 | 533.0 | 68.1 | 356.0 | 45.4 |

| 12.7 | X.S | 222.0 | 45.0 | 533.0 | 90.0 | 356.0 | 60.0 | |||

| 400 | 16” | 406.4 | 9.52 | STD | 254.0 | 45.0 | 610.0 | 89.3 | 406.0 | 59.5 |

| 12.7 | X.S | 254.0 | 59.0 | 610.0 | 118.0 | 406.0 | 78.7 | |||

| 450 | 18” | 457.0 | 9.52 | STD | 286.0 | 56.5 | 686.0 | 113.0 | 457.0 | 75.6 |

| 12.7 | X.S | 286.0 | 75.0 | 686.0 | 150.0 | 457.0 | 100.0 | |||

| 500 | 20” | 508.0 | 9.52 | STD | 318.0 | 85.0 | 762.0 | 140.0 | 508.0 | 93.5 |

| 12.7 | X.S | 318.0 | 112.5 | 762.0 | 186.0 | 508.0 | 124.0 | |||

| 600 | 24” | 610.00 | 9.52 | STD | 381.0 | 101.5 | 914.0 | 203.0 | 610.0 | 135.0 |

| 12.7 | X.S | 381.0 | 134.5 | 914.0 | 269.0 | 610.0 | 179.0 | |||

Size Of Monel 400/ K500 Forged fitting

| NPS (inch) | Pipe Schedule. | OD (inch) | Wall Thick. (in) | Temperature | ||||

| 100 Fitting | 200 Fitting | 300 Fitting | 400 Fitting | 500 Fitting | ||||

| Allowable Stress | ||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | ||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 |

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | |

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | |

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 |

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | |

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | |

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 |

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | |

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | |

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 |

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | |

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | |

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 |

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | |

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | |

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 |

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | |

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | |

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 |

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | |

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | |

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 |

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | |

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | |

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 |

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | |

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | |

Weight Chart Of Monel 400/ K500 Forged fitting

| Normal Pipe Sizes | A | B | QTY | Weight In KG |

| ¼ | 0.81 | 0.88 | 160 | 0.20 |

| ⁄ | 0.97 | 1.00 | 130 | 0.26 |

| ½ | 1.12 | 1.31 | 100 | 0.57 |

| ¾ | 1.31 | 1.5 | 75 | 0.71 |

| 1 | 1.5 | 1.81 | 40 | 1.08 |

| 1 ¼ | 1.75 | 2.19 | 25 | 1.68 |

| 1 ½ | 2.00 | 2.44 | 18 | 2.38 |

| 2 | 2.38 | 2.97 | 10 | 3.55 |

| 2 ½ | 3.00 | 3.62 | 4 | 6.22 |

| 3 | 3.38 | 4.31 | 2 | 10.36 |

| 4 | 4.19 | 5.75 | 1 | 23.91 |

Pressure Rating Of Monel 400/ K500 Forged fitting

| Pressure-Temperature | |||||

| Temperature | Class | ||||

| 150 | 300 | ||||

| 1/4 - 1 inch. | 1 1/4 - 2 inch. | 2 1/2 - 3 inch. | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | - | 935 | 750 | 560 |

| 450 | 232 | - | 725 | 600 | 475 |

| 500 | 260 | - | 510 | 450 | 385 |

| 550 | 288 | - | 300 | 300 | 300 |

industrial use fitting for Monel 400/ K500 Forged fitting

Price Of Monel 400/ K500 Forged fitting

| High Nickel Alloys Elbow | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Equal Tee | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Reducing Tee | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Cross | USD $8.11 - $20.21 / Piece (FOB Price) on request |

| High Nickel Alloys Cap | USD $8.11 - $20.21 / Piece (FOB Price) on request |

Application Of Monel 400/ K500 Forged fitting

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Monel 400/ K500 Forged fitting

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

Packing Of Monel 400/ K500 Forged fitting

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates