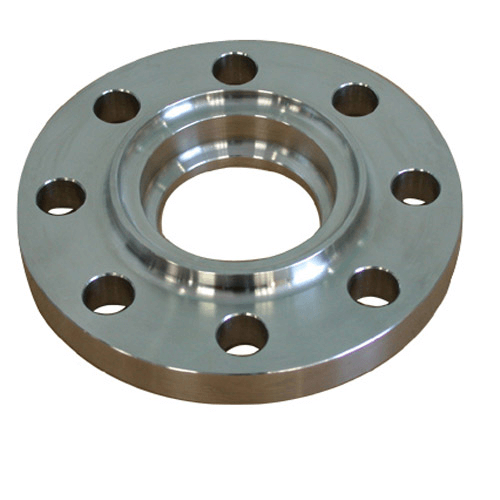

Stainless Steel 15-5 PH Flanges

UNS S15500 Lap Joint Flanges, UNS S15500 Screwed Flanges, DIN 1.4545 Forging Facing Flanges, SS 15-5PH Weld Neck Flanges A/ B, SS 15-5PH Slip On Flange, Stainless Steel 15-5PH Flanges Bolts, ASTM A182 SS 15-5PH Forged Flanges.

About Stainless Steel 15-5 PH Flanges

A variation of 17-4 PH is 15-5 PH stainless steel, sometimes referred to as UNS S15500 or XM-12. The low-carbon form of stainless steel alloy 304 is known as 15-5PH flanges. Martensitic stainless steel of type 15-5 PH is robust, resistant to corrosion, mechanically effective at 600°F, and has high toughness in both the longitudinal and transverse directions. Scale and distortion are lessened by short heating at low temperatures. Due to its many properties, stainless steel 15-5 PH flanges are employed in various industries. The features of the flanges include corrosion resistance, pitting corrosion resistance, crack protection against corrosion, and numerous other resistance qualities.

Properties of SS 15-5 PH Flanges :

- A martensitic, high-alloy steel with precipitation hardening is called 15-5 PH. It has exceptional strength and hardness in terms of mechanical qualities and exceptional corrosion resistance.

- It demonstrates notable environmental tolerance, including resistance to low concentrations of acetic acid, salt, nitric acid, and sodium hydroxide.

- Before forging, the stock has to be evenly heated to 2150–2200°F (1180–1205°C) and kept there for an hour. It is not recommended to forge material below 1850° F.

- Before further processing, forged steel should be cooled to below 90° F (32° C) for the best particle sizes and mechanical qualities. Before hardening, factories must chemically treat a substance.

- Resistance and shielded fusion welding techniques may both fuse this grade of flanges well. Due to the potential for carbon pickup, oxyacetylene soldering is not advised. Stresses should be kept to a minimum when designing weld joints.

- DIN 1.4545 flanges may be age hardened in a single step using a low temperature treatment, and its manufacturing properties are comparable to those of other cryogenic treatment grades.

- A minimum amount of delta ferrite is produced by balancing the chemical analysis, which results in better longitudinal toughness and ductility as well as high forgeability.

- Due to its resistance to forming any carbon layer inside the machine or device, it enhances weldability. The fact that it has less carbon makes this feasible.

SS 15-5 PH Flanges have the following chemical composition :

In 15-5 PH stainless steel, there are considerable amounts of chromium, nickel, and copper. It’s possible to find traces of tantalum, columbium, silicon, manganese, phosphorus, sulfur, and each of these elements in amounts that don’t go beyond 1% of the compositional total.

Usage for SS 15-5 PH Flanges :

Creep tension and rupture-free qualities are flanges’ main advantages. It has more flexibility and resistance. Stainless Steel 15-5Ph Flanges are distinguished by their lack of carbide layer production, which guards against machine wear. Its mechanical power is increased by its high density and significant elongation capacity. It is utilized in commercial settings for waste treatment, expansion joints, and the manufacture of aircraft machinery.

SS Weldo / Nipo Flanges Exporter, DIN 1.4545 Reducing Flanges Manufacturer, SS 15-5PH Groove & Tongue Flanges Stockist, ASME SA182 SS 15-5PH Spectacle Blind Flanges Exporter, Stainless Steel 15-5PH Flanges Bolts Exporter.

Specification of Stainless Steel 15-5 PH Flanges

| Specification | ASTM A182 / ASME SA182 |

| Dimension Standard | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| DIN Flanges | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673. |

| JIS Flanges | JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K |

| BS Flanges | BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H. |

Ready stock of Flanges available for Stainless Steel 15-5 PH Flanges

Equivalent Grades of Stainless Steel 15-5 PH Flanges

| STANDARD | WERKSTOFF NR. | UNS |

| SS 15-5PH | 1.4545 | S15500 |

Chemical Composition of Stainless Steel 15-5 PH Flanges

| Grade | C | Cb+Ta | Cr | Cu | Fe | Mn | Ni | P | S | Si |

| SS 15-5 PH | 0.07 max | 0.15-0.45 | 14.0-15.0 | 2.5-4.5 | Bal | 1.0 max | 3.5-5.5 | 0.04 max | 0.03 max | 1.0 max |

Mechanical Properties of Stainless Steel 15-5 PH Flanges

| Grade | Tensile Strength ksi (MPa) | Yield Strength 0.2% ksi (min) | Elongation % | Hardness (Rockwell) MAX |

| SS 15-5 PH | 161,000 | 140,000 | 7.6% | C35 |

Other Types of Flanges of Stainless Steel 15-5 PH Flanges

Dimensions Standard Of Stainless Steel 15-5 PH Flanges

| Nominal Size | Outside Diameter (OD) | Min. Thickness (T) | RF Dia. (R) | No. of Bolt Holes | Diameter of Holes | Bolt Circle (BC) | SO Bore ID (SB) | WN Bore ID (WB) | Dia. Hub Base (HB) | Dia. of Hub Top (HT) | SO LTH (SL) | WN LTH (WL) |

| 1⁄2 | 3.50 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.50 | 1.05 | 0.56 | 2.00 |

| 1 | 4.25 | 0.50 | 2.00 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.50 | 4 | 0.62 | 3.50 | 1.70 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5.00 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.90 | 0.81 | 2.38 |

| 2 | 6.00 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7.00 | 0.81 | 4.12 | 4 | 0.75 | 5.50 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.50 | 0.88 | 5.00 | 4 | 0.75 | 6.00 | 3.57 | 3.07 | 4.25 | 3.50 | 1.12 | 2.69 |

| 31⁄2 | 8.50 | 0.88 | 5.50 | 8 | 0.75 | 7.00 | 4.07 | 3.55 | 4.81 | 4.00 | 1.19 | 2.75 |

| 4 | 9.00 | 0.88 | 6.19 | 8 | 0.75 | 7.50 | 4.57 | 4.03 | 5.31 | 4.50 | 1.25 | 2.94 |

| 5 | 10.00 | 0.88 | 7.31 | 8 | 0.88 | 8.50 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11.00 | 0.94 | 8.50 | 8 | 0.88 | 9.50 | 6.72 | 6.07 | 7.56 | 6.63 | 1.50 | 3.44 |

| 8 | 13.50 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16.00 | 1.12 | 12.75 | 12 | 1.00 | 14.25 | 10.88 | 10.02 | 12.00 | 10.75 | 1.88 | 3.94 |

| 12 | 19.00 | 1.19 | 15.00 | 12 | 1.00 | 17.00 | 12.88 | 12.00 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21.00 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14.00 | 2.19 | 4.94 |

| 16 | 23.50 | 1.38 | 18.50 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18.00 | 16.00 | 2.44 | 4.94 |

| 18 | 25.00 | 1.50 | 21.00 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18.00 | 2.62 | 5.44 |

| 20 | 27.50 | 1.62 | 23.00 | 20 | 1.25 | 25.00 | 20.20 | 19.25 | 22.00 | 20.00 | 2.81 | 5.62 |

| 22 | 29.50 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22.00 | 3.07 | 5.82 |

| 24 | 32.00 | 1.81 | 27.25 | 20 | 1.38 | 29.50 | 24.25 | 23.25 | 26.12 | 24.00 | 3.19 | 5.94 |

Size Of Stainless Steel 15-5 PH Flanges

| Nom. Pipe Size | o | T1 | R | x | No.2/Dia. of Holes | Bolt Circle Dia. | L21 | H | B23 | L | B | r | L34 | B3 | D |

| 1/2 | 3.50 | 0.44 | 1.38 | 1.19 | 4-0.62 | 2.38 | 1.88 | 0.84 | 0.62 | 0.62 | 0.88 | 0.12 | 0.62 | 0.90 | 0.38 |

| 3/4 | 3.88 | 0.50 | 1.69 | 1.50 | 4-0.62 | 2.75 | 2.06 | 1.05 | 0.82 | 0.62 | 1.09 | 0.12 | 0.62 | 1.11 | 0.44 |

| 1 | 4.25 | 0.56 | 2.00 | 1.94 | 4-0.62 | 3.12 | 2.19 | 1.32 | 1.05 | 0.69 | 1.36 | 0.12 | 0.69 | 1.38 | 0.50 |

| 1-1/4 | 4.62 | 0.62 | 2.50 | 2.31 | 4-0.62 | 3.50 | 2.25 | 1.66 | 1.38 | 0.81 | 1.70 | 0.19 | 0.81 | 1.72 | 0.56 |

| 1-1/2 | 5.00 | 0.68 | 2.88 | 2.56 | 4-0.62 | 3.88 | 2.44 | 1.90 | 1.61 | 0.88 | 1.95 | 0.25 | 0.88 | 1.97 | 0.62 |

| 2 | 6.00 | 0.75 | 3.62 | 3.06 | 4-0.75 | 4.75 | 2.50 | 2.38 | 2.07 | 1.00 | 2.44 | 0.31 | 1.00 | 2.46 | 0.69 |

| 2-1/2 | 7.00 | 0.88 | 4.12 | 3.56 | 4-0.75 | 5.50 | 2.75 | 2.88 | 2.47 | 1.12 | 2.94 | 0.31 | 1.12 | 2.97 | 0.75 |

| 3 | 7.50 | 0.94 | 5.00 | 4.25 | 4-0.75 | 6.00 | 2.75 | 3.50 | 3.07 | 1.19 | 3.57 | 0.38 | 1.19 | 3.60 | 0.81 |

| 3-1/2 | 8.50 | 0.94 | 5.50 | 4.81 | 8-0.75 | 7.00 | 2.81 | 4.00 | 3.55 | 1.25 | 4.07 | 0.38 | 1.25 | 4.10 | 0.88 |

| 4 | 9.00 | 0.94 | 6.19 | 5.31 | 8-0.75 | 7.50 | 3.00 | 4.50 | 4.03 | 1.31 | 4.57 | 0.44 | 1.31 | 4.60 | 0.94 |

| 5 | 10.00 | 0.94 | 7.31 | 6.44 | 8-0.88 | 8.50 | 3.50 | 5.56 | 5.05 | 1.44 | 5.66 | 0.44 | 1.44 | 5.69 | 0.94 |

| 6 | 11.00 | 1.00 | 8.50 | 7.56 | 8-0.88 | 9.50 | 3.50 | 6.63 | 6.07 | 1.56 | 6.72 | 0.50 | 1.56 | 6.75 | 1.06 |

| 8 | 13.50 | 1.12 | 10.62 | 9.69 | 8-0.88 | 11.75 | 4.00 | 8.63 | 7.98 | 1.75 | 8.72 | 0.50 | 1.75 | 8.75 | 1.25 |

| 10 | 16.00 | 1.19 | 12.75 | 12.00 | 12-1.00 | 14.25 | 4.00 | 10.75 | 10.02 | 1.94 | 10.88 | 0.50 | 1.94 | 10.92 | 1.31 |

| 12 | 19.00 | 1.25 | 15.00 | 14.38 | 12-1.00 | 17.00 | 4.50 | 12.75 | 12.00 | 2.19 | 12.88 | 0.50 | 2.19 | 12.92 | 1.56 |

| 14 | 21.00 | 1.38 | 16.25 | 15.75 | 12-1.12 | 18.75 | 5.00 | 14.00 | 13.25 | 2.25 | 14.14 | 0.50 | 3.12 | 14.18 | 1.63 |

| 16 | 23.50 | 1.44 | 18.50 | 18.00 | 16-1.12 | 21.25 | 5.00 | 16.00 | 15.25 | 2.50 | 16.16 | 0.50 | 3.44 | 16.19 | 1.75 |

| 18 | 25.00 | 1.56 | 21.00 | 19.88 | 16-1.25 | 22.75 | 5.50 | 18.00 | 17.25 | 2.69 | 18.18 | 0.50 | 3.81 | 18.20 | 1.94 |

| 20 | 27.50 | 1.69 | 23.00 | 22.00 | 20-1.25 | 25.00 | 5.69 | 20.00 | 19.25 | 2.88 | 20.20 | 0.50 | 4.06 | 20.25 | 2.13 |

| 22 | 29.50 | 1.81 | 25.25 | 24.25 | 20-1.38 | 27.25 | 5.88 | 22.00 | 21.25 | 3.13 | 22.22 | 0.50 | 4.25 | 22.25 | 2.38 |

| 24 | 32.00 | 1.88 | 27.25 | 26.12 | 20-1.38 | 29.50 | 6.00 | 24.00 | 23.25 | 3.25 | 24.25 | 0.50 | 4.38 | 24.25 | 2.50 |

Weight Chart Of Stainless Steel 15-5 PH Flanges

| Standard Of Flanges | Class Of Flanges | Diameter Of Flanges | Diameter Of Bolt Circle | Bolts Number | Size Of Bolt | Bolt Hole Diameter |

| AS4087 Flanges | PN14 Flanges | 95 | 67 | 4 | M12 | 14 |

| AS 2129 Flange | Table C Flanges | 95 | 67 | 4 | 13 | 14 |

| Table D Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table E Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table F Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table H Flanges | 114 | 83 | 4 | 16 | 17 | |

| Table J Flanges | 114 | 83 | 4 | 16 | 17 | |

| ANSI B16.5 Flanges | ANSI 150 Flanges | 89 | 60 | 4 | 13 | 16 |

| ANSI 300 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 600 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 900 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ANSI 1500 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ISO 7005 (DIN) Flange | PN6 Flanges | 80 | 55 | 4 | M10 | 11 |

| PN10 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN16 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN20 Flanges | 90 | 60.5 | 4 | M14 | 16 | |

| PN25 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN40 Flanges | 95 | 65 | 4 | M12 | 14 |

Pressure Rating Of Stainless Steel 15-5 PH Flanges

| Temp. ℃ | Pressure-ASME temperature rating for B16.47 by class, bar | |||||

| 75 | 150 | 300 | 400 | 600 | 900 | |

| -29 to 38 | 10.0 | 20.0 | 51.7 | 68.9 | 103.4 | 155.1 |

| 50 | 9.8 | 19.5 | 51.7 | 68.9 | 103.4 | 155.1 |

| 100 | 8.8 | 17.7 | 50.7 | 67.5 | 101.3 | 152.0 |

| 150 | 7.9 | 15.8 | 45.9 | 61.2 | 91.9 | 137.8 |

| 200 | 6.9 | 13.8 | 42.7 | 56.9 | 85.3 | 128.0 |

| 250 | 6.0 | 12.1 | 40.5 | 53.9 | 80.9 | 121.4 |

| 300 | 5.1 | 10.2 | 38.9 | 51.8 | 77.7 | 116.6 |

industrial use flanges for Stainless Steel 15-5 PH Flanges

Price Of Stainless Steel 15-5 PH Flanges

| Stainless Steel Forged Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Blind Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Slip On Flange | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Socketweld Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Long Weld Neck Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

Application Of Stainless Steel 15-5 PH Flanges

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Stainless Steel 15-5 PH Flanges

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

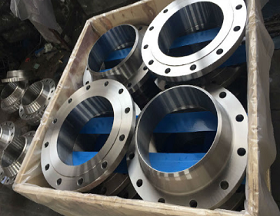

Packing Of Stainless Steel 15-5 PH Flanges

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

DIN 1.4545 Ring Type Joint Flanges Catalogue, DIN 1.4545 Reducing Flanges Price List, ASTM A182 SS 15-5PH Forged Flanges Weight Chart, UNS S15500 Screwed Flanges Weight Calculator, 15-5PH SS Flat Flanges Weight Calculator, UNS S15500 WNRF Flanges Price List In India, 15-5PH SS Spades Ring Spacers Flanges Price Per Kg, UNS S15500 Orifice Flanges Weight Chart, ASME SA182 SS 15-5PH Spectacle Blind Flanges Weight Chart, 15-5PH SS Expander Flanges Weight Calculator, SS 15-5PH Slip On Flange Price Per Kg, 15-5PH SS Weldo / Nipo Flanges At Factory Price, Stainless Steel 15-5PH Square Flanges Price List.

Stainless Steel 15-5PH Flanges Bolts Exporter in Patna, UNS S15500 Loose Flanges Manufacturer in Daman, ASTM A182 SS 15-5PH Forged Flanges Manufacturer in Bengaluru, UNS S15500 Screwed Flanges Stockist in Nagpur, UNS S15500 WNRF Flanges Stockist in Karnataka, Stainless Steel 15-5PH Blind Flange Stockist in Pimpri-Chinchwad, UNS S15500 Orifice Flanges Stockist in Bangalore, DIN 1.4545 RTJ Flanges Stockist in Gujarat, DIN 1.4545 Threaded Flanges Stockist in Ahmedabad, DIN 1.4545 Reducing Flanges Manufacturer in Vadodara, ASTM A182 15-5PH SORF Flanges Supplier in Bihar, 15-5PH SS Spades Ring Spacers Flanges Manufacturer in Ahmedabad.

15-5PH SS Flat Flanges Stockist in Australia, DIN 1.4545 Threaded Flanges Stockist in Malaysia, SS 15-5PH Weld Neck Flanges A/ B Exporter in Yemen, UNS S15500 Screwed Flanges Stockist in Libya, 15-5PH SS Weldneck Flanges Exporter in Kuwait, SS 15-5PH SWRF Flanges Manufacturer in Israel, 15-5PH SS Weldo / Nipo Flanges Exporter in Indonesia, UNS S15500 Loose Flanges Manufacturer in Italy, UNS S15500 WNRF Flanges Stockist in Saudi Arabia, ASTM A182 SS 15-5PH Forged Flanges Manufacturer in USA, ASME SA182 15-5PH Socketweld Flange Stockist in UAE, DIN 1.4545 RTJ Flanges Stockist in UK, UNS S15500 Orifice Flanges Exporter in South Africa.

Stainless Steel Flanges

- Stainless Steel 304/ 304L/ 304H Flanges

- Stainless Steel 309 Flanges

- Stainless Steel 310/ 310S Flanges

- Stainless Steel 316/ 316L/ 316Ti Flanges

- Stainless Steel 317/317L Flanges

- Stainless Steel 321 Flanges

- Stainless Steel 347/ 347H Flanges

- Stainless Steel 410/ 420/ 430 Flanges

- Stainless Steel 446 Flanges

- Stainless Steel 904L Flanges

- Stainless Steel 15-5 PH Flanges

- Stainless Steel 17-4 PH Flanges