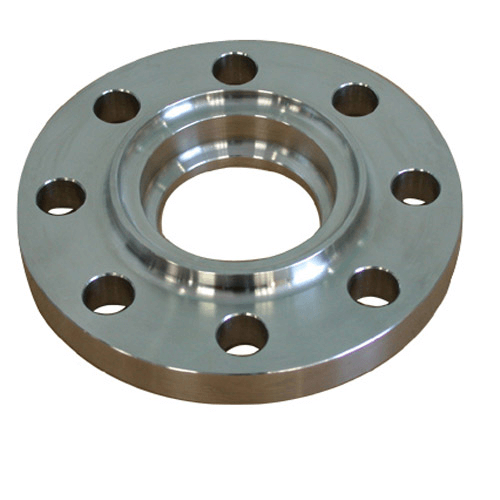

Stainless Steel 309 Flanges

UNS S30900 Forge Flange, 309 SS Reducing Flange, Stainless Steel 309 Blind Flange, SS 309 Longweld Neck Flange, ASTM A182 SS 309 Weldneck Flange, DIN 1.4828 Flat Flange, SS 309 Slip On Flange, UNS S30900 Square Flange.

About Stainless Steel 309 Flanges

Properties of stainless steel 309 Flanges:

- These components increase the grade’s flexibility and durability. The significant chromium and nickel strength provide superior robustness and scalability.

- Stainless steel 309/309S flanges provide good corrosion resistance, embrittlement, and tension cracking.

- These flanges offer high heat and corrosion resistance.

- Alloy 309 may be used at temperatures up to 1832°F (1000°C) in sulfur-containing atmospheres because of its substantial chromium and reduced nickel content.

- Due to its modest resistance to carbon absorption, the alloy is not advised for usage in severely carburising environments.

- Alloy 309 Flanges can be used in applications that involve mild oxidation, nitriding, cementing, and thermal cycling; however, factories must lower the high service heat.

- Because this alloy has less carbon, the grade is more stable and weldable.

- Due to its superior chemical and mechanical characteristics, SS 309/309S blind flanges are frequently employed as boilers and heat exchangers.

- These flanges have extraordinarily high yield and tensile strengths.

- The 309 Stainless Steel Flanges are subjected to mechanical tensile testing and other hardness tests to ensure optimum satisfaction.

Applications of 309 Stainless Steel Flanges:

Grade 309 flanges can endure extreme heat, inclement weather, and chloride-rich environments. These materials are the name of a family of corrosion-resistant steels, not a single substance. Depending on the diverse capabilities, an extensive range of Stainless Steel 309 Flanges are available in different diameters, wall thicknesses, and ranges of measures. Since SS 309 Flanges can be reinforced at 1038 degrees Celsius before being extinguished in water, they also protect the marine environment. The flanges are a necessary component of modern life and are used incommercial applications, such as automotive headers, food manufacturing lines, and mechanical parts.Because of their tensile strength, damage tolerance, and simplicity of maintenance, stainless steel flanges are the ideal material for various applications. Additionally, it is 100% recyclable and has a long-life cycle.

309 SS SORF Flange, SS 309 RTJ Flange, 309 SS Threaded Flange, DIN 1.4828 Orifice Flange, ASME SA182 SS 309 Socketweld Flange, UNS S30900 Groove Flange, DIN 1.4828 Lap Joint Flange.

Specification of Stainless Steel 309 Flanges

| Specification | ASTM A182 / ASME SA182 |

| Dimension Standard | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| DIN Flanges | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673. |

| JIS Flanges | JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K |

| BS Flanges | BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H. |

Ready stock of Flanges available for Stainless Steel 309 Flanges

Equivalent Grades of Stainless Steel 309 Flanges

| STANDARD | WERKSTOFF NR. | UNS |

| SS 309 | 1.4828 | S30900 |

Chemical Composition of Stainless Steel 309 Flanges

| Grade | C | Ni | Si | S | Mn | P | Cr | Mo |

| SS 309 | 0.20 max | 12.0 – 15.0 | 0.75 max | 0.03 max | 2.00 max | 0.045 max | 22.0 – 24.0 | – |

Mechanical Properties of Stainless Steel 309 Flanges

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| SS 309 | 8.0 g/cm3 | 1455°C (2650°F) | Psi – 89900 , MPa – 620 | Psi – 45000 , MPa – 310 | 45 % |

Other Types of Flanges of Stainless Steel 309 Flanges

Dimensions Standard Of Stainless Steel 309 Flanges

| Nominal Size | Outside Diameter (OD) | Min. Thickness (T) | RF Dia. (R) | No. of Bolt Holes | Diameter of Holes | Bolt Circle (BC) | SO Bore ID (SB) | WN Bore ID (WB) | Dia. Hub Base (HB) | Dia. of Hub Top (HT) | SO LTH (SL) | WN LTH (WL) |

| 1⁄2 | 3.50 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.50 | 1.05 | 0.56 | 2.00 |

| 1 | 4.25 | 0.50 | 2.00 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.50 | 4 | 0.62 | 3.50 | 1.70 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5.00 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.90 | 0.81 | 2.38 |

| 2 | 6.00 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7.00 | 0.81 | 4.12 | 4 | 0.75 | 5.50 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.50 | 0.88 | 5.00 | 4 | 0.75 | 6.00 | 3.57 | 3.07 | 4.25 | 3.50 | 1.12 | 2.69 |

| 31⁄2 | 8.50 | 0.88 | 5.50 | 8 | 0.75 | 7.00 | 4.07 | 3.55 | 4.81 | 4.00 | 1.19 | 2.75 |

| 4 | 9.00 | 0.88 | 6.19 | 8 | 0.75 | 7.50 | 4.57 | 4.03 | 5.31 | 4.50 | 1.25 | 2.94 |

| 5 | 10.00 | 0.88 | 7.31 | 8 | 0.88 | 8.50 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11.00 | 0.94 | 8.50 | 8 | 0.88 | 9.50 | 6.72 | 6.07 | 7.56 | 6.63 | 1.50 | 3.44 |

| 8 | 13.50 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16.00 | 1.12 | 12.75 | 12 | 1.00 | 14.25 | 10.88 | 10.02 | 12.00 | 10.75 | 1.88 | 3.94 |

| 12 | 19.00 | 1.19 | 15.00 | 12 | 1.00 | 17.00 | 12.88 | 12.00 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21.00 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14.00 | 2.19 | 4.94 |

| 16 | 23.50 | 1.38 | 18.50 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18.00 | 16.00 | 2.44 | 4.94 |

| 18 | 25.00 | 1.50 | 21.00 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18.00 | 2.62 | 5.44 |

| 20 | 27.50 | 1.62 | 23.00 | 20 | 1.25 | 25.00 | 20.20 | 19.25 | 22.00 | 20.00 | 2.81 | 5.62 |

| 22 | 29.50 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22.00 | 3.07 | 5.82 |

| 24 | 32.00 | 1.81 | 27.25 | 20 | 1.38 | 29.50 | 24.25 | 23.25 | 26.12 | 24.00 | 3.19 | 5.94 |

Size Of Stainless Steel 309 Flanges

| Nom. Pipe Size | o | T1 | R | x | No.2/Dia. of Holes | Bolt Circle Dia. | L21 | H | B23 | L | B | r | L34 | B3 | D |

| 1/2 | 3.50 | 0.44 | 1.38 | 1.19 | 4-0.62 | 2.38 | 1.88 | 0.84 | 0.62 | 0.62 | 0.88 | 0.12 | 0.62 | 0.90 | 0.38 |

| 3/4 | 3.88 | 0.50 | 1.69 | 1.50 | 4-0.62 | 2.75 | 2.06 | 1.05 | 0.82 | 0.62 | 1.09 | 0.12 | 0.62 | 1.11 | 0.44 |

| 1 | 4.25 | 0.56 | 2.00 | 1.94 | 4-0.62 | 3.12 | 2.19 | 1.32 | 1.05 | 0.69 | 1.36 | 0.12 | 0.69 | 1.38 | 0.50 |

| 1-1/4 | 4.62 | 0.62 | 2.50 | 2.31 | 4-0.62 | 3.50 | 2.25 | 1.66 | 1.38 | 0.81 | 1.70 | 0.19 | 0.81 | 1.72 | 0.56 |

| 1-1/2 | 5.00 | 0.68 | 2.88 | 2.56 | 4-0.62 | 3.88 | 2.44 | 1.90 | 1.61 | 0.88 | 1.95 | 0.25 | 0.88 | 1.97 | 0.62 |

| 2 | 6.00 | 0.75 | 3.62 | 3.06 | 4-0.75 | 4.75 | 2.50 | 2.38 | 2.07 | 1.00 | 2.44 | 0.31 | 1.00 | 2.46 | 0.69 |

| 2-1/2 | 7.00 | 0.88 | 4.12 | 3.56 | 4-0.75 | 5.50 | 2.75 | 2.88 | 2.47 | 1.12 | 2.94 | 0.31 | 1.12 | 2.97 | 0.75 |

| 3 | 7.50 | 0.94 | 5.00 | 4.25 | 4-0.75 | 6.00 | 2.75 | 3.50 | 3.07 | 1.19 | 3.57 | 0.38 | 1.19 | 3.60 | 0.81 |

| 3-1/2 | 8.50 | 0.94 | 5.50 | 4.81 | 8-0.75 | 7.00 | 2.81 | 4.00 | 3.55 | 1.25 | 4.07 | 0.38 | 1.25 | 4.10 | 0.88 |

| 4 | 9.00 | 0.94 | 6.19 | 5.31 | 8-0.75 | 7.50 | 3.00 | 4.50 | 4.03 | 1.31 | 4.57 | 0.44 | 1.31 | 4.60 | 0.94 |

| 5 | 10.00 | 0.94 | 7.31 | 6.44 | 8-0.88 | 8.50 | 3.50 | 5.56 | 5.05 | 1.44 | 5.66 | 0.44 | 1.44 | 5.69 | 0.94 |

| 6 | 11.00 | 1.00 | 8.50 | 7.56 | 8-0.88 | 9.50 | 3.50 | 6.63 | 6.07 | 1.56 | 6.72 | 0.50 | 1.56 | 6.75 | 1.06 |

| 8 | 13.50 | 1.12 | 10.62 | 9.69 | 8-0.88 | 11.75 | 4.00 | 8.63 | 7.98 | 1.75 | 8.72 | 0.50 | 1.75 | 8.75 | 1.25 |

| 10 | 16.00 | 1.19 | 12.75 | 12.00 | 12-1.00 | 14.25 | 4.00 | 10.75 | 10.02 | 1.94 | 10.88 | 0.50 | 1.94 | 10.92 | 1.31 |

| 12 | 19.00 | 1.25 | 15.00 | 14.38 | 12-1.00 | 17.00 | 4.50 | 12.75 | 12.00 | 2.19 | 12.88 | 0.50 | 2.19 | 12.92 | 1.56 |

| 14 | 21.00 | 1.38 | 16.25 | 15.75 | 12-1.12 | 18.75 | 5.00 | 14.00 | 13.25 | 2.25 | 14.14 | 0.50 | 3.12 | 14.18 | 1.63 |

| 16 | 23.50 | 1.44 | 18.50 | 18.00 | 16-1.12 | 21.25 | 5.00 | 16.00 | 15.25 | 2.50 | 16.16 | 0.50 | 3.44 | 16.19 | 1.75 |

| 18 | 25.00 | 1.56 | 21.00 | 19.88 | 16-1.25 | 22.75 | 5.50 | 18.00 | 17.25 | 2.69 | 18.18 | 0.50 | 3.81 | 18.20 | 1.94 |

| 20 | 27.50 | 1.69 | 23.00 | 22.00 | 20-1.25 | 25.00 | 5.69 | 20.00 | 19.25 | 2.88 | 20.20 | 0.50 | 4.06 | 20.25 | 2.13 |

| 22 | 29.50 | 1.81 | 25.25 | 24.25 | 20-1.38 | 27.25 | 5.88 | 22.00 | 21.25 | 3.13 | 22.22 | 0.50 | 4.25 | 22.25 | 2.38 |

| 24 | 32.00 | 1.88 | 27.25 | 26.12 | 20-1.38 | 29.50 | 6.00 | 24.00 | 23.25 | 3.25 | 24.25 | 0.50 | 4.38 | 24.25 | 2.50 |

Weight Chart Of Stainless Steel 309 Flanges

| Standard Of Flanges | Class Of Flanges | Diameter Of Flanges | Diameter Of Bolt Circle | Bolts Number | Size Of Bolt | Bolt Hole Diameter |

| AS4087 Flanges | PN14 Flanges | 95 | 67 | 4 | M12 | 14 |

| AS 2129 Flange | Table C Flanges | 95 | 67 | 4 | 13 | 14 |

| Table D Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table E Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table F Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table H Flanges | 114 | 83 | 4 | 16 | 17 | |

| Table J Flanges | 114 | 83 | 4 | 16 | 17 | |

| ANSI B16.5 Flanges | ANSI 150 Flanges | 89 | 60 | 4 | 13 | 16 |

| ANSI 300 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 600 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 900 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ANSI 1500 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ISO 7005 (DIN) Flange | PN6 Flanges | 80 | 55 | 4 | M10 | 11 |

| PN10 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN16 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN20 Flanges | 90 | 60.5 | 4 | M14 | 16 | |

| PN25 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN40 Flanges | 95 | 65 | 4 | M12 | 14 |

Pressure Rating Of Stainless Steel 309 Flanges

| Temp. ℃ | Pressure-ASME temperature rating for B16.47 by class, bar | |||||

| 75 | 150 | 300 | 400 | 600 | 900 | |

| -29 to 38 | 10.0 | 20.0 | 51.7 | 68.9 | 103.4 | 155.1 |

| 50 | 9.8 | 19.5 | 51.7 | 68.9 | 103.4 | 155.1 |

| 100 | 8.8 | 17.7 | 50.7 | 67.5 | 101.3 | 152.0 |

| 150 | 7.9 | 15.8 | 45.9 | 61.2 | 91.9 | 137.8 |

| 200 | 6.9 | 13.8 | 42.7 | 56.9 | 85.3 | 128.0 |

| 250 | 6.0 | 12.1 | 40.5 | 53.9 | 80.9 | 121.4 |

| 300 | 5.1 | 10.2 | 38.9 | 51.8 | 77.7 | 116.6 |

industrial use flanges for Stainless Steel 309 Flanges

Price Of Stainless Steel 309 Flanges

| Stainless Steel Forged Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Blind Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Slip On Flange | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Socketweld Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Long Weld Neck Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

Application Of Stainless Steel 309 Flanges

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Stainless Steel 309 Flanges

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

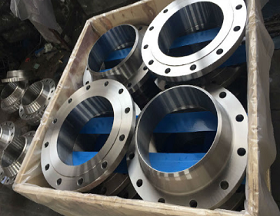

Packing Of Stainless Steel 309 Flanges

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

Stainless Steel Flanges

- Stainless Steel 304/ 304L/ 304H Flanges

- Stainless Steel 309 Flanges

- Stainless Steel 310/ 310S Flanges

- Stainless Steel 316/ 316L/ 316Ti Flanges

- Stainless Steel 317/317L Flanges

- Stainless Steel 321 Flanges

- Stainless Steel 347/ 347H Flanges

- Stainless Steel 410/ 420/ 430 Flanges

- Stainless Steel 446 Flanges

- Stainless Steel 904L Flanges

- Stainless Steel 15-5 PH Flanges

- Stainless Steel 17-4 PH Flanges