Stainless Steel 904L Flanges

SS 904L RTJ Flange, UNS N08904 Groove Flange, 904L SS Reducing Flange, SS 904L Longweld Neck Flange, Stainless Steel 904L Blind Flange, DIN 1.4539 Orifice Flange, DIN 1.4539 Flat Flange.

About Stainless Steel 904L Flanges

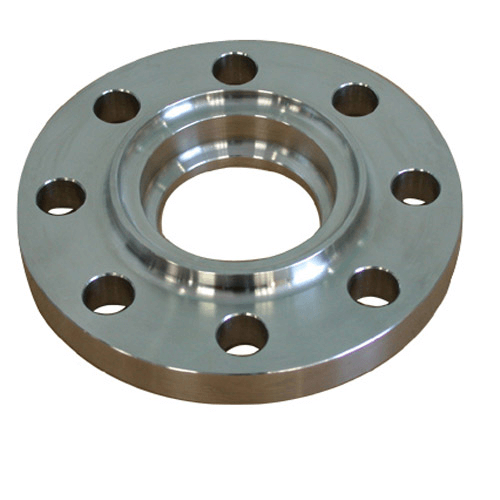

Stainless Steel 904L Flanges, which have a nickel concentration of 25%, are an excellent substitute for most traditional stainless steel. Chloride stress corrosion cracking can happen to conventional stainless steels like these Stainless Steel 904L Flanges under certain circumstances. With increased nickel and molybdenum content, these flanges become more resistant to SSC. As a result, austenitic stainless steels with superior performance, such as these Stainless Steel 904L Flanges, have excellent resistance to SSC.

SS 904L Flanges are used to connect pipes and many sorts of industrial equipment. Bolts are also utilised to fit the flanges when they are being joined. Flanges are designed to support heavy loads. It is composed of steel and has a circular form. These flanges are beneficial in many businesses where high temperatures occur often.

Properties of Stainless Steel 904L Flanges:

- The combination of nickel, chromium, and molybdenum gives it exceptional strength and corrosion resistance.

- These flanges also have strong mechanical properties, such as a minimum yield and tensile strength of 220MPa and 490 MPa respectively.

- The substance has a high melting point of 1350 degrees Celsius. A pipe’s terminus is sealed off with an Alloy 904L Blind Flange, usually permanently.

- The substance is a 904-steel grade with minimal carbon content. As a result, these flanges may be easily welded and formed without running the danger of intergranular corrosion or grain formation from carbide precipitation during welding.

- A plate is connected to the SS 904L flange to provide more room for welding, bolting, and other attaching techniques.

- The flanges are specified by ASTM B649 and meet several ANSI, ASME, DIN, and EN standards.

- These flanges come in various diameters, from 12 to 48 inches, and pressure classes.

- Weld neck elevated face flanges are ASM 904L flanges. These flanges may be found in pressure categories from 150 to 2500 and PN6 to PN64, and they feature raised faces and welded necks for enhanced strength.

- Because they are made to maintain pressure in a high-pressure location and are robust to diluted acids like sulphuric acids in petroleum and chemical facilities and oil refineries, 904L stainless steel flanges are frequently used to seal the tip of the pipe of a pressure vessel.

- These stainless steel lap joint flanges are immune to chloride cracking from stress corrosion.

- They are a more affordable option for moving acidic slurries. These stainless steel 904L threaded flanges are heat and oxidation resistant.

Uses of Stainless Steel 904L Flanges:

904L SS flanges are used in many industries, such as the pharma, petrochemical, marine, seawater, and power-generating sectors. Heating systems, boilers, condensers, the paper and pulp industry, offshore oil drilling, and the manufacture of petrochemical and saltwater equipment all employ SS Flanges.

904L SS Threaded Flange, SS 904L Slip On Flange, ASTM A182 SS 904L Weldneck Flange, ASME SA182 SS 904L Socketweld Flange, UNS N08904 Forge Flange, 904L SS SORF Flange, UNS N08904 Square Flange, DIN 1.4539 Lap Joint Flange.

Specification of Stainless Steel 904L Flanges

| Specification | ASTM A182 / ASME SA182 |

| Dimension Standard | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| DIN Flanges | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673. |

| JIS Flanges | JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K |

| BS Flanges | BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H. |

Ready stock of Flanges available for Stainless Steel 904L Flanges

Equivalent Grades of Stainless Steel 904L Flanges

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

Chemical Composition of Stainless Steel 904L Flanges

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

| SS 904L | 0.020 max | 2.00 max | 1.00 max | 0.040 max | 0.030 max | 19.00 – 23.00 | 4.00 – 5.00 max | 23.00 – 28.00 | 1.00 – 2.00 |

Mechanical Properties of Stainless Steel 904L Flanges

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.95 g/cm3 | 1350 °C (2460 °F) | Psi – 71000 , MPa – 490 | Psi – 32000 , MPa – 220 | 35 % |

Other Types of Flanges of Stainless Steel 904L Flanges

Dimensions Standard Of Stainless Steel 904L Flanges

| Nominal Size | Outside Diameter (OD) | Min. Thickness (T) | RF Dia. (R) | No. of Bolt Holes | Diameter of Holes | Bolt Circle (BC) | SO Bore ID (SB) | WN Bore ID (WB) | Dia. Hub Base (HB) | Dia. of Hub Top (HT) | SO LTH (SL) | WN LTH (WL) |

| 1⁄2 | 3.50 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.50 | 1.05 | 0.56 | 2.00 |

| 1 | 4.25 | 0.50 | 2.00 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.50 | 4 | 0.62 | 3.50 | 1.70 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5.00 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.90 | 0.81 | 2.38 |

| 2 | 6.00 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7.00 | 0.81 | 4.12 | 4 | 0.75 | 5.50 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.50 | 0.88 | 5.00 | 4 | 0.75 | 6.00 | 3.57 | 3.07 | 4.25 | 3.50 | 1.12 | 2.69 |

| 31⁄2 | 8.50 | 0.88 | 5.50 | 8 | 0.75 | 7.00 | 4.07 | 3.55 | 4.81 | 4.00 | 1.19 | 2.75 |

| 4 | 9.00 | 0.88 | 6.19 | 8 | 0.75 | 7.50 | 4.57 | 4.03 | 5.31 | 4.50 | 1.25 | 2.94 |

| 5 | 10.00 | 0.88 | 7.31 | 8 | 0.88 | 8.50 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11.00 | 0.94 | 8.50 | 8 | 0.88 | 9.50 | 6.72 | 6.07 | 7.56 | 6.63 | 1.50 | 3.44 |

| 8 | 13.50 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16.00 | 1.12 | 12.75 | 12 | 1.00 | 14.25 | 10.88 | 10.02 | 12.00 | 10.75 | 1.88 | 3.94 |

| 12 | 19.00 | 1.19 | 15.00 | 12 | 1.00 | 17.00 | 12.88 | 12.00 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21.00 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14.00 | 2.19 | 4.94 |

| 16 | 23.50 | 1.38 | 18.50 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18.00 | 16.00 | 2.44 | 4.94 |

| 18 | 25.00 | 1.50 | 21.00 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18.00 | 2.62 | 5.44 |

| 20 | 27.50 | 1.62 | 23.00 | 20 | 1.25 | 25.00 | 20.20 | 19.25 | 22.00 | 20.00 | 2.81 | 5.62 |

| 22 | 29.50 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22.00 | 3.07 | 5.82 |

| 24 | 32.00 | 1.81 | 27.25 | 20 | 1.38 | 29.50 | 24.25 | 23.25 | 26.12 | 24.00 | 3.19 | 5.94 |

Size Of Stainless Steel 904L Flanges

| Nom. Pipe Size | o | T1 | R | x | No.2/Dia. of Holes | Bolt Circle Dia. | L21 | H | B23 | L | B | r | L34 | B3 | D |

| 1/2 | 3.50 | 0.44 | 1.38 | 1.19 | 4-0.62 | 2.38 | 1.88 | 0.84 | 0.62 | 0.62 | 0.88 | 0.12 | 0.62 | 0.90 | 0.38 |

| 3/4 | 3.88 | 0.50 | 1.69 | 1.50 | 4-0.62 | 2.75 | 2.06 | 1.05 | 0.82 | 0.62 | 1.09 | 0.12 | 0.62 | 1.11 | 0.44 |

| 1 | 4.25 | 0.56 | 2.00 | 1.94 | 4-0.62 | 3.12 | 2.19 | 1.32 | 1.05 | 0.69 | 1.36 | 0.12 | 0.69 | 1.38 | 0.50 |

| 1-1/4 | 4.62 | 0.62 | 2.50 | 2.31 | 4-0.62 | 3.50 | 2.25 | 1.66 | 1.38 | 0.81 | 1.70 | 0.19 | 0.81 | 1.72 | 0.56 |

| 1-1/2 | 5.00 | 0.68 | 2.88 | 2.56 | 4-0.62 | 3.88 | 2.44 | 1.90 | 1.61 | 0.88 | 1.95 | 0.25 | 0.88 | 1.97 | 0.62 |

| 2 | 6.00 | 0.75 | 3.62 | 3.06 | 4-0.75 | 4.75 | 2.50 | 2.38 | 2.07 | 1.00 | 2.44 | 0.31 | 1.00 | 2.46 | 0.69 |

| 2-1/2 | 7.00 | 0.88 | 4.12 | 3.56 | 4-0.75 | 5.50 | 2.75 | 2.88 | 2.47 | 1.12 | 2.94 | 0.31 | 1.12 | 2.97 | 0.75 |

| 3 | 7.50 | 0.94 | 5.00 | 4.25 | 4-0.75 | 6.00 | 2.75 | 3.50 | 3.07 | 1.19 | 3.57 | 0.38 | 1.19 | 3.60 | 0.81 |

| 3-1/2 | 8.50 | 0.94 | 5.50 | 4.81 | 8-0.75 | 7.00 | 2.81 | 4.00 | 3.55 | 1.25 | 4.07 | 0.38 | 1.25 | 4.10 | 0.88 |

| 4 | 9.00 | 0.94 | 6.19 | 5.31 | 8-0.75 | 7.50 | 3.00 | 4.50 | 4.03 | 1.31 | 4.57 | 0.44 | 1.31 | 4.60 | 0.94 |

| 5 | 10.00 | 0.94 | 7.31 | 6.44 | 8-0.88 | 8.50 | 3.50 | 5.56 | 5.05 | 1.44 | 5.66 | 0.44 | 1.44 | 5.69 | 0.94 |

| 6 | 11.00 | 1.00 | 8.50 | 7.56 | 8-0.88 | 9.50 | 3.50 | 6.63 | 6.07 | 1.56 | 6.72 | 0.50 | 1.56 | 6.75 | 1.06 |

| 8 | 13.50 | 1.12 | 10.62 | 9.69 | 8-0.88 | 11.75 | 4.00 | 8.63 | 7.98 | 1.75 | 8.72 | 0.50 | 1.75 | 8.75 | 1.25 |

| 10 | 16.00 | 1.19 | 12.75 | 12.00 | 12-1.00 | 14.25 | 4.00 | 10.75 | 10.02 | 1.94 | 10.88 | 0.50 | 1.94 | 10.92 | 1.31 |

| 12 | 19.00 | 1.25 | 15.00 | 14.38 | 12-1.00 | 17.00 | 4.50 | 12.75 | 12.00 | 2.19 | 12.88 | 0.50 | 2.19 | 12.92 | 1.56 |

| 14 | 21.00 | 1.38 | 16.25 | 15.75 | 12-1.12 | 18.75 | 5.00 | 14.00 | 13.25 | 2.25 | 14.14 | 0.50 | 3.12 | 14.18 | 1.63 |

| 16 | 23.50 | 1.44 | 18.50 | 18.00 | 16-1.12 | 21.25 | 5.00 | 16.00 | 15.25 | 2.50 | 16.16 | 0.50 | 3.44 | 16.19 | 1.75 |

| 18 | 25.00 | 1.56 | 21.00 | 19.88 | 16-1.25 | 22.75 | 5.50 | 18.00 | 17.25 | 2.69 | 18.18 | 0.50 | 3.81 | 18.20 | 1.94 |

| 20 | 27.50 | 1.69 | 23.00 | 22.00 | 20-1.25 | 25.00 | 5.69 | 20.00 | 19.25 | 2.88 | 20.20 | 0.50 | 4.06 | 20.25 | 2.13 |

| 22 | 29.50 | 1.81 | 25.25 | 24.25 | 20-1.38 | 27.25 | 5.88 | 22.00 | 21.25 | 3.13 | 22.22 | 0.50 | 4.25 | 22.25 | 2.38 |

| 24 | 32.00 | 1.88 | 27.25 | 26.12 | 20-1.38 | 29.50 | 6.00 | 24.00 | 23.25 | 3.25 | 24.25 | 0.50 | 4.38 | 24.25 | 2.50 |

Weight Chart Of Stainless Steel 904L Flanges

| Standard Of Flanges | Class Of Flanges | Diameter Of Flanges | Diameter Of Bolt Circle | Bolts Number | Size Of Bolt | Bolt Hole Diameter |

| AS4087 Flanges | PN14 Flanges | 95 | 67 | 4 | M12 | 14 |

| AS 2129 Flange | Table C Flanges | 95 | 67 | 4 | 13 | 14 |

| Table D Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table E Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table F Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table H Flanges | 114 | 83 | 4 | 16 | 17 | |

| Table J Flanges | 114 | 83 | 4 | 16 | 17 | |

| ANSI B16.5 Flanges | ANSI 150 Flanges | 89 | 60 | 4 | 13 | 16 |

| ANSI 300 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 600 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 900 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ANSI 1500 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ISO 7005 (DIN) Flange | PN6 Flanges | 80 | 55 | 4 | M10 | 11 |

| PN10 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN16 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN20 Flanges | 90 | 60.5 | 4 | M14 | 16 | |

| PN25 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN40 Flanges | 95 | 65 | 4 | M12 | 14 |

Pressure Rating Of Stainless Steel 904L Flanges

| Temp. ℃ | Pressure-ASME temperature rating for B16.47 by class, bar | |||||

| 75 | 150 | 300 | 400 | 600 | 900 | |

| -29 to 38 | 10.0 | 20.0 | 51.7 | 68.9 | 103.4 | 155.1 |

| 50 | 9.8 | 19.5 | 51.7 | 68.9 | 103.4 | 155.1 |

| 100 | 8.8 | 17.7 | 50.7 | 67.5 | 101.3 | 152.0 |

| 150 | 7.9 | 15.8 | 45.9 | 61.2 | 91.9 | 137.8 |

| 200 | 6.9 | 13.8 | 42.7 | 56.9 | 85.3 | 128.0 |

| 250 | 6.0 | 12.1 | 40.5 | 53.9 | 80.9 | 121.4 |

| 300 | 5.1 | 10.2 | 38.9 | 51.8 | 77.7 | 116.6 |

industrial use flanges for Stainless Steel 904L Flanges

Price Of Stainless Steel 904L Flanges

| Stainless Steel Forged Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Blind Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Slip On Flange | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Socketweld Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Long Weld Neck Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

Application Of Stainless Steel 904L Flanges

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Stainless Steel 904L Flanges

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

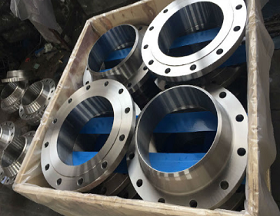

Packing Of Stainless Steel 904L Flanges

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

SS 904L Slip On Flange Price Per Kg, ASME SA182 SS 904L Socketweld Flange At Factory Price, UNS N08904 Forge Flange Price List In India, SS 904L Longweld Neck Flange At Factory Price, 904L SS Reducing Flange At Factory Price, Stainless Steel 904L Blind Flange Price List, DIN 1.4539 Lap Joint Flange Catalogue, DIN 1.4539 Flat Flange Catalogue, 904L SS SORF Flange Weight Calculator, UNS N08904 Square Flange Price List In India, 904L SS Threaded Flange Weight Calculator, UNS N08904 Groove Flange Weight Chart, ASTM A182 SS 904L Weldneck Flange Weight Chart, SS 904L RTJ Flange Price Per Kg, DIN 1.4539 Orifice Flange Price List.

ASTM A182 SS 904L Weldneck Flange Manufacturer in Bengaluru, DIN 1.4539 Lap Joint Flange Stockist in Ahmedabad, SS 904L Slip On Flange Supplier in Coimbatore, SS 904L RTJ Flange Stockist in Nashik, DIN 1.4539 Orifice Flange Manufacturer in Vadodara, UNS N08904 Groove Flange Stockist in Bangalore, Stainless Steel 904L Blind Flange Stockist in Pimpri-Chinchwad, SS 904L Longweld Neck Flange Supplier in Pune, 904L SS Reducing Flange Supplier in Hyderabad, UNS N08904 Forge Flange Manufacturer in Mumbai, 904L SS SORF Flange Stockist in Bharuch, 904L SS Threaded Flange Supplier in Hyderabad, ASME SA182 SS 904L Socketweld Flange Stockist in Chennai, UNS N08904 Square Flange Supplier in Daman, DIN 1.4539 Flat Flange in Gujarat.

DIN 1.4539 Lap Joint Flange Stockist in Malaysia, UNS N08904 Square Flange Supplier in Italy, DIN 1.4539 Flat Flange in UK, SS 904L RTJ Flange Stockist in Oman, Stainless Steel 904L Blind Flange Stockist in UK, DIN 1.4539 Orifice Flange Manufacturer in Vietnam, SS 904L Longweld Neck Flange Supplier in Qatar, UNS N08904 Groove Flange Exporter in South Africa, 904L SS SORF Flange Stockist in Australia, ASTM A182 SS 904L Weldneck Flange Manufacturer in USA, 904L SS Reducing Flange Exporter in Indonesia, 904L SS Threaded Flange Exporter in Kuwait, SS 904L Slip On Flange Supplier in Saudi Arabia, UNS N08904 Forge Flange Manufacturer in Singapore, ASME SA182 SS 904L Socketweld Flange Stockist in UAE.

Stainless Steel Flanges

- Stainless Steel 304/ 304L/ 304H Flanges

- Stainless Steel 309 Flanges

- Stainless Steel 310/ 310S Flanges

- Stainless Steel 316/ 316L/ 316Ti Flanges

- Stainless Steel 317/317L Flanges

- Stainless Steel 321 Flanges

- Stainless Steel 347/ 347H Flanges

- Stainless Steel 410/ 420/ 430 Flanges

- Stainless Steel 446 Flanges

- Stainless Steel 904L Flanges

- Stainless Steel 15-5 PH Flanges

- Stainless Steel 17-4 PH Flanges