Stainless Steel 317/317L Flanges

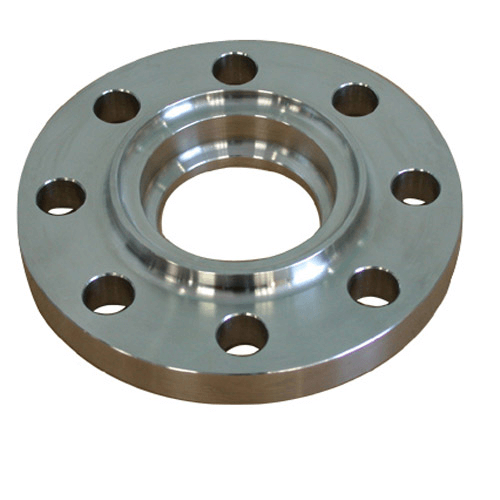

ASTM A182 SS 317 Weldneck Flange, 317 SS SORF Flange, UNS S31700 Forge Flange, Stainless Steel 317 Blind Flange, DIN 1.4449 Flat Flange, DIN 1.4449 Lap Joint Flange, UNS S31700 Groove Flange, ASME SA182 SS 317 Socketweld Flange.

About Stainless Steel 317/317L Flanges

Compared to common chromium-nickel alloys like SS 304 and SS 316L, SS 317 Flanges is a molybdenum-containing austenitic alloy with improved chemical resistance. Chromium-nickel stainless steel austenitic of type 317 SS Flanges has exceptional corrosion resistance. The high molybdenum concentration enhances this grade’s ability to resist pitting. High tensile strength and creep strength are both characteristics of this grade. Type 317 stainless steel is more durable than type 304. This alloy may be heated to between 2100 and 2300F. This alloy can be cold-hammered, which increases its hardness and toughness even though it cannot be heated.

Properties of Stainless Steel 317/317L Flanges:

- This flange grade is brought on by corrosion, resulting from borders where chromium carbide has precipitated. SS 317/317L Flanges may be produced and drawn quickly but cannot be hardened by any heat treatment.

- The corrosion resistance of SS 317L flanges is often weaker than the usual austenitic stainless steel 317 flanges.

- While hard work can improve strength and hardness, these flanges do not react to heat treatment.

- The main advantage of these flanges (and other grades of stainless steel that precipitate harden) is that they are often provided in the solution-treated form when they are barely machinable and may be age-hardened to obtain relatively high strengths.

- Because the temperature during this ageing process of these flanges is so low, no noticeable deformation occurs.

- Additionally, the flanges offer stronger creep, stress-to-rupture, and tensile strength levels at higher temperatures.

- Compared to alloys of other stainless-steel grades, alloy 317L with a low carbon content offers higher corrosion resistance.

- SS 317L is resistant to sensitisation experienced during welding and other heat treatments because it has less carbon.

Applications of Stainless Steel 317/317L Flanges:

In applications where it is prohibited to anneal after welding, chromium-nickel austenitic stainless steel with a low carbon content is also utilized, and that steel is designated as SS 317/317L. Additionally, consumers can use it for applications that call for excellent corrosion resistance. The pulp and paper sector, energy exchangers, dynamite, air quality control, food, and drinks all employ materials of this grade. The 317L Stainless Steel Flanges are utilized in various industries and applications. In pipe systems, slurry tanks, compressors, tanks, valves, and other structures, SS 317 flanges are often employed. These Flanges are designed to function in harsh environments like the desulphurisation of flue gas systems. It is employed in cementing, thermal cycling, oxidising, and nitriding applications. It is also considered a non-flammable material and highly resistant to marine atmosphere. These flanges aid in preventing leaks in high-pressure pipes. These flanges give access to a line for measuring liquids or gases. They can be mounted beside flow nozzles or orifice plates.

SS 317 RTJ Flange, SS 317 Slip On Flange, UNS S31700 Square Flange, 317 SS Reducing Flange, 317 SS Threaded Flange, SS 317 Longweld Neck Flange, DIN 1.4449 Orifice Flange.

Specification of Stainless Steel 317/317L Flanges

| Specification | ASTM A182 / ASME SA182 |

| Dimension Standard | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| DIN Flanges | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673. |

| JIS Flanges | JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K |

| BS Flanges | BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H. |

Ready stock of Flanges available for Stainless Steel 317/317L Flanges

Equivalent Grades of Stainless Steel 317/317L Flanges

| STANDARD | UNS | WNR. | JIS | EN |

| SS 317 | S31700 | 1.4449 | SUS 317 | - |

| SS 317L | S31703 | 1.4438 | SUS 317L | X2CrNiMo18-15-4 |

Chemical Composition of Stainless Steel 317/317L Flanges

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| 317 | 0.08 max | 2 max | 1 max | 0.040 max | 0.03 max | 18 – 20 | 3 – 4 | 11 – 14 | - |

| 317L | 0.035 max | 2 max | 1 max | 0.040 max | 0.03 max | 18 – 20 | 3 – 4 | 11 – 15 | - |

Mechanical Properties of Stainless Steel 317/317L Flanges

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Other Types of Flanges of Stainless Steel 317/317L Flanges

Dimensions Standard Of Stainless Steel 317/317L Flanges

| Nominal Size | Outside Diameter (OD) | Min. Thickness (T) | RF Dia. (R) | No. of Bolt Holes | Diameter of Holes | Bolt Circle (BC) | SO Bore ID (SB) | WN Bore ID (WB) | Dia. Hub Base (HB) | Dia. of Hub Top (HT) | SO LTH (SL) | WN LTH (WL) |

| 1⁄2 | 3.50 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.50 | 1.05 | 0.56 | 2.00 |

| 1 | 4.25 | 0.50 | 2.00 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.50 | 4 | 0.62 | 3.50 | 1.70 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5.00 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.90 | 0.81 | 2.38 |

| 2 | 6.00 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7.00 | 0.81 | 4.12 | 4 | 0.75 | 5.50 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.50 | 0.88 | 5.00 | 4 | 0.75 | 6.00 | 3.57 | 3.07 | 4.25 | 3.50 | 1.12 | 2.69 |

| 31⁄2 | 8.50 | 0.88 | 5.50 | 8 | 0.75 | 7.00 | 4.07 | 3.55 | 4.81 | 4.00 | 1.19 | 2.75 |

| 4 | 9.00 | 0.88 | 6.19 | 8 | 0.75 | 7.50 | 4.57 | 4.03 | 5.31 | 4.50 | 1.25 | 2.94 |

| 5 | 10.00 | 0.88 | 7.31 | 8 | 0.88 | 8.50 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11.00 | 0.94 | 8.50 | 8 | 0.88 | 9.50 | 6.72 | 6.07 | 7.56 | 6.63 | 1.50 | 3.44 |

| 8 | 13.50 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16.00 | 1.12 | 12.75 | 12 | 1.00 | 14.25 | 10.88 | 10.02 | 12.00 | 10.75 | 1.88 | 3.94 |

| 12 | 19.00 | 1.19 | 15.00 | 12 | 1.00 | 17.00 | 12.88 | 12.00 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21.00 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14.00 | 2.19 | 4.94 |

| 16 | 23.50 | 1.38 | 18.50 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18.00 | 16.00 | 2.44 | 4.94 |

| 18 | 25.00 | 1.50 | 21.00 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18.00 | 2.62 | 5.44 |

| 20 | 27.50 | 1.62 | 23.00 | 20 | 1.25 | 25.00 | 20.20 | 19.25 | 22.00 | 20.00 | 2.81 | 5.62 |

| 22 | 29.50 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22.00 | 3.07 | 5.82 |

| 24 | 32.00 | 1.81 | 27.25 | 20 | 1.38 | 29.50 | 24.25 | 23.25 | 26.12 | 24.00 | 3.19 | 5.94 |

Size Of Stainless Steel 317/317L Flanges

| Nom. Pipe Size | o | T1 | R | x | No.2/Dia. of Holes | Bolt Circle Dia. | L21 | H | B23 | L | B | r | L34 | B3 | D |

| 1/2 | 3.50 | 0.44 | 1.38 | 1.19 | 4-0.62 | 2.38 | 1.88 | 0.84 | 0.62 | 0.62 | 0.88 | 0.12 | 0.62 | 0.90 | 0.38 |

| 3/4 | 3.88 | 0.50 | 1.69 | 1.50 | 4-0.62 | 2.75 | 2.06 | 1.05 | 0.82 | 0.62 | 1.09 | 0.12 | 0.62 | 1.11 | 0.44 |

| 1 | 4.25 | 0.56 | 2.00 | 1.94 | 4-0.62 | 3.12 | 2.19 | 1.32 | 1.05 | 0.69 | 1.36 | 0.12 | 0.69 | 1.38 | 0.50 |

| 1-1/4 | 4.62 | 0.62 | 2.50 | 2.31 | 4-0.62 | 3.50 | 2.25 | 1.66 | 1.38 | 0.81 | 1.70 | 0.19 | 0.81 | 1.72 | 0.56 |

| 1-1/2 | 5.00 | 0.68 | 2.88 | 2.56 | 4-0.62 | 3.88 | 2.44 | 1.90 | 1.61 | 0.88 | 1.95 | 0.25 | 0.88 | 1.97 | 0.62 |

| 2 | 6.00 | 0.75 | 3.62 | 3.06 | 4-0.75 | 4.75 | 2.50 | 2.38 | 2.07 | 1.00 | 2.44 | 0.31 | 1.00 | 2.46 | 0.69 |

| 2-1/2 | 7.00 | 0.88 | 4.12 | 3.56 | 4-0.75 | 5.50 | 2.75 | 2.88 | 2.47 | 1.12 | 2.94 | 0.31 | 1.12 | 2.97 | 0.75 |

| 3 | 7.50 | 0.94 | 5.00 | 4.25 | 4-0.75 | 6.00 | 2.75 | 3.50 | 3.07 | 1.19 | 3.57 | 0.38 | 1.19 | 3.60 | 0.81 |

| 3-1/2 | 8.50 | 0.94 | 5.50 | 4.81 | 8-0.75 | 7.00 | 2.81 | 4.00 | 3.55 | 1.25 | 4.07 | 0.38 | 1.25 | 4.10 | 0.88 |

| 4 | 9.00 | 0.94 | 6.19 | 5.31 | 8-0.75 | 7.50 | 3.00 | 4.50 | 4.03 | 1.31 | 4.57 | 0.44 | 1.31 | 4.60 | 0.94 |

| 5 | 10.00 | 0.94 | 7.31 | 6.44 | 8-0.88 | 8.50 | 3.50 | 5.56 | 5.05 | 1.44 | 5.66 | 0.44 | 1.44 | 5.69 | 0.94 |

| 6 | 11.00 | 1.00 | 8.50 | 7.56 | 8-0.88 | 9.50 | 3.50 | 6.63 | 6.07 | 1.56 | 6.72 | 0.50 | 1.56 | 6.75 | 1.06 |

| 8 | 13.50 | 1.12 | 10.62 | 9.69 | 8-0.88 | 11.75 | 4.00 | 8.63 | 7.98 | 1.75 | 8.72 | 0.50 | 1.75 | 8.75 | 1.25 |

| 10 | 16.00 | 1.19 | 12.75 | 12.00 | 12-1.00 | 14.25 | 4.00 | 10.75 | 10.02 | 1.94 | 10.88 | 0.50 | 1.94 | 10.92 | 1.31 |

| 12 | 19.00 | 1.25 | 15.00 | 14.38 | 12-1.00 | 17.00 | 4.50 | 12.75 | 12.00 | 2.19 | 12.88 | 0.50 | 2.19 | 12.92 | 1.56 |

| 14 | 21.00 | 1.38 | 16.25 | 15.75 | 12-1.12 | 18.75 | 5.00 | 14.00 | 13.25 | 2.25 | 14.14 | 0.50 | 3.12 | 14.18 | 1.63 |

| 16 | 23.50 | 1.44 | 18.50 | 18.00 | 16-1.12 | 21.25 | 5.00 | 16.00 | 15.25 | 2.50 | 16.16 | 0.50 | 3.44 | 16.19 | 1.75 |

| 18 | 25.00 | 1.56 | 21.00 | 19.88 | 16-1.25 | 22.75 | 5.50 | 18.00 | 17.25 | 2.69 | 18.18 | 0.50 | 3.81 | 18.20 | 1.94 |

| 20 | 27.50 | 1.69 | 23.00 | 22.00 | 20-1.25 | 25.00 | 5.69 | 20.00 | 19.25 | 2.88 | 20.20 | 0.50 | 4.06 | 20.25 | 2.13 |

| 22 | 29.50 | 1.81 | 25.25 | 24.25 | 20-1.38 | 27.25 | 5.88 | 22.00 | 21.25 | 3.13 | 22.22 | 0.50 | 4.25 | 22.25 | 2.38 |

| 24 | 32.00 | 1.88 | 27.25 | 26.12 | 20-1.38 | 29.50 | 6.00 | 24.00 | 23.25 | 3.25 | 24.25 | 0.50 | 4.38 | 24.25 | 2.50 |

Weight Chart Of Stainless Steel 317/317L Flanges

| Standard Of Flanges | Class Of Flanges | Diameter Of Flanges | Diameter Of Bolt Circle | Bolts Number | Size Of Bolt | Bolt Hole Diameter |

| AS4087 Flanges | PN14 Flanges | 95 | 67 | 4 | M12 | 14 |

| AS 2129 Flange | Table C Flanges | 95 | 67 | 4 | 13 | 14 |

| Table D Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table E Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table F Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table H Flanges | 114 | 83 | 4 | 16 | 17 | |

| Table J Flanges | 114 | 83 | 4 | 16 | 17 | |

| ANSI B16.5 Flanges | ANSI 150 Flanges | 89 | 60 | 4 | 13 | 16 |

| ANSI 300 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 600 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 900 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ANSI 1500 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ISO 7005 (DIN) Flange | PN6 Flanges | 80 | 55 | 4 | M10 | 11 |

| PN10 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN16 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN20 Flanges | 90 | 60.5 | 4 | M14 | 16 | |

| PN25 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN40 Flanges | 95 | 65 | 4 | M12 | 14 |

Pressure Rating Of Stainless Steel 317/317L Flanges

| Temp. ℃ | Pressure-ASME temperature rating for B16.47 by class, bar | |||||

| 75 | 150 | 300 | 400 | 600 | 900 | |

| -29 to 38 | 10.0 | 20.0 | 51.7 | 68.9 | 103.4 | 155.1 |

| 50 | 9.8 | 19.5 | 51.7 | 68.9 | 103.4 | 155.1 |

| 100 | 8.8 | 17.7 | 50.7 | 67.5 | 101.3 | 152.0 |

| 150 | 7.9 | 15.8 | 45.9 | 61.2 | 91.9 | 137.8 |

| 200 | 6.9 | 13.8 | 42.7 | 56.9 | 85.3 | 128.0 |

| 250 | 6.0 | 12.1 | 40.5 | 53.9 | 80.9 | 121.4 |

| 300 | 5.1 | 10.2 | 38.9 | 51.8 | 77.7 | 116.6 |

industrial use flanges for Stainless Steel 317/317L Flanges

Price Of Stainless Steel 317/317L Flanges

| Stainless Steel Forged Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Blind Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Slip On Flange | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Socketweld Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Long Weld Neck Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

Application Of Stainless Steel 317/317L Flanges

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Stainless Steel 317/317L Flanges

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

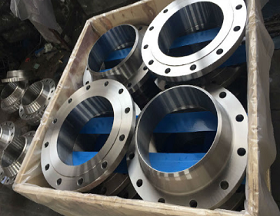

Packing Of Stainless Steel 317/317L Flanges

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

Stainless Steel Flanges

- Stainless Steel 304/ 304L/ 304H Flanges

- Stainless Steel 309 Flanges

- Stainless Steel 310/ 310S Flanges

- Stainless Steel 316/ 316L/ 316Ti Flanges

- Stainless Steel 317/317L Flanges

- Stainless Steel 321 Flanges

- Stainless Steel 347/ 347H Flanges

- Stainless Steel 410/ 420/ 430 Flanges

- Stainless Steel 446 Flanges

- Stainless Steel 904L Flanges

- Stainless Steel 15-5 PH Flanges

- Stainless Steel 17-4 PH Flanges